Flexibility and low cost for the transformation of sheet

Mariluz Penalva, division of Industry and Transport of

During the last years, and more specifically from the presentation of the strategy Horizon 2020, Europe has changed the industrial orientation that had followed during almost a decade. With the new orientation the industrial state will have to change his up to now declining participation in the GDP and increase it with new technologies, new procedures, new organisational structures, that situate again to the continent in his traditional position of leadership.

The sector of the transformation of sheet lives a moment of clear expansion. The increase of sales of vehicles supports from automotive sector to the good moment of the aeronautical sector component manufacturing sector component manufacturing sector, with record of manufacture of aeroplanes every year, and complements with the renewal of the sector appliance by means of products with greater value with regard to the previous generation.

The products with pieces of metallic sheet, in all his varieties, are in full force. The European companies that wish to ensure his quota of market and international presence have to offer products more sophisticated, more competitive and appeals for the final customer, incorporating new designs, new materials and a continuous adaptation to the demand. Between the new technologies of process of metallic sheet, the conformed incremental is in peak by his potential to reduce time of development of product, shortening the phase of design of pieces that later will manufacture by means of traditional technologies. More still, it can be considered a valid productive option when it needs manufacture unitary components or with ratios of production reduced.

In this article review some of the potential applications of the conformed incremental from the experience purchased by Tecnalia in this technology.

Description of the technology

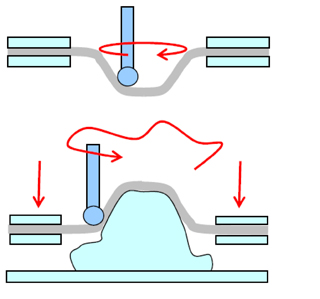

The conformed incremental is a process of transformation of sheet based in the punctual plastic deformation and progressive of a subject sheet by his perimeter. The deformation realizar by means of to the action of a tool that acts to way of punzón and that follows a path established controlled numerically as it illustrates the Figure 1.

The process carries out without need to use coin, being able to or not using a support of support manufactured in materials of low cost (wood, resin or similar) and easy to mechanise. Therefore, the basic equipment consists only in a tooling to tie up the sheet, the tool of deformation and a system CNC (robot, fresadora) that moves the tool according to the path programmed. Therefore, they are not necessary big investments and exists an increasing tendency to develop the process in cells robotizadas of low cost like the showed in the Figure 2.

Appears 2. Robotic cell of conformed incremental installed by Tecnalia in the PFT Hérault (France).

As it realizar the process with or without support, see the Figure 3, can speak of Two Point Incremental Forming (TPIF) or of Single Point Incremental Forming (SPIF) respectively. The flexibility in front of changes of design is maximum when it opts by a configuration SPIF. However, with the configuration TPIF obtain surfaces of greater geometrical precision and double curvatures.

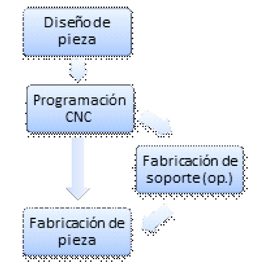

By the characteristics of the process the sequence to manufacture a piece results very simple, as it can appreciate in the Figure 4. From the geometry of the piece proceeds to the generation of the program of CNC that controls the movements of the machine/robot. It is in this point in where it is necessary a deep knowledge of the process and of the material to define the paths and parameters of process that give place to a valid piece. The last phase is the manufacture in himself same although when it opts by the type of configuration TPIF is precise to manufacture previously the support of support.

Technical feasibility of the manufacture of components of appliance

Tecnalia has analysed the technical feasibility to manufacture prototypes for components of sheet of products consummate of white line, by means of conformed incremental. The application of the technology will allow to validate better the designs, shortening the phase of design and avoiding changes of last hour (modifications in the matrices once that his manufacture has been launched or even finalised) which repercutirá positively in the costs and terms of delivery of the product.

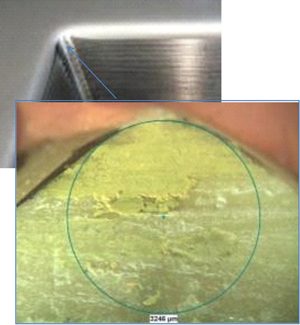

Nowadays the prototypes that realizar in the sector are geometrical approximations obtained from retales cut and soldiers. With the state of the current art of the conformed incremental is also possible to tackle an approximate reproduction of the geometry of many of the components of this sector. However, it is necessary to take into account that the obtaining of some frequent geometrical details in the components, such as small radii of agreement, eyelashes for the setting or recess of little depth to lodge logos is not still evident. If it wishes accelerate the phase of design and delete the need of modifications once launched the industrialisation of the component is necessary that the prototype reproduce faithfully the geometry of design. From the knowledge of base of the previously purchased technology, Tecnalia has collaborated with Fagor Industrial to develop tools and paths of conformed specific with which is possible to reproduce the different geometrical details of components of his catalogue of products. The Figure 6 and the Figure 5 show to way of example two of the details produced.

Once developed the tools and the specific paths is possible to combine them between yes, together with tools and standard paths to produce prototypes with the geometry wished. The Figure 7 sample a piece demostrador of a component of the door of an industrial washing machine. The demostrador includes to scale real all the geometrical details of the component (radios of agreement of 1mm, recess of 2mm of depth, corners of radius 3mm).

Development of the technology for the aeronautical sector component manufacturing sector component manufacturing sector

The technologies employed in the aeronautical sector component manufacturing sector component manufacturing sector to produce components of metallic sheet, especially the realizar with materials termorresistentes (alloys of titanium and of basic nickel), are based in the employment of specific toolings particularly costly and with terms of delivery very long. In this case also, the conformed incremental has the necessary characteristics to obtain previous prototypes without need of these specific toolings. With this would be possible to speed up the test of validation of the designs and minimise the frequent iterations between the phases of design and industrialisation, avoiding like this the modification of toolings that penalises costs and terms. More still, the process can be also a technology of utility to manufacture loose pieces of models of aeroplane more ancient or series with ratios of production very low.

Tecnalia leads the project INMA, funded by the FP7 of the EU (agreement No. 266208), oriented to the development and application of of the conformed incremental for the aeronautical sector component manufacturing sector component manufacturing sector, with the collaboration of Airbus France and WSK Rzeszów (Group Pratt & Whitney Canada) as potential final users of the technology.

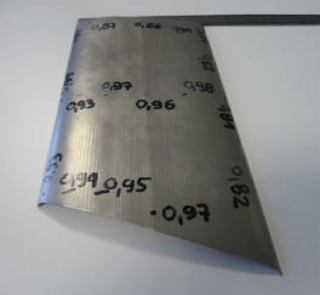

In the frame of the project one of the most notable activities has been the definition and adecuación of the process to the deformation in hot of You6To the-4V. For this has implemented the system of the Figure 8 that allows to realizar the operation of conformed to temperature controlled and homogénea. Likewise, they have fixed the optimum conditions of operation regarding temperature of work and conditions of warming and cooling of the sheet. Also it has been necessary the design of able specific tools to guarantee a superficial integrity (superficial finishing, microgrietas, layer alpha) acceptable by the strict norms of the sector.

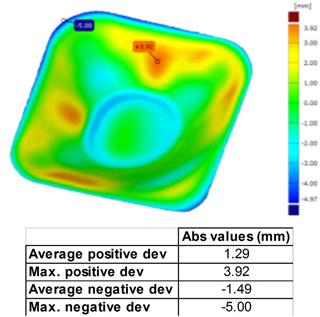

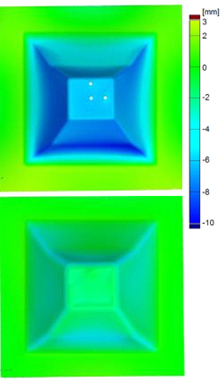

The results showed in the Figure 9 confirm the potential of the technology to manufacture pieces without specific toolings. Nevertheless, it is necessary to improve still the geometrical precision of the pieces. For this is collaborating with one of the partners of the project in the application of an intelligent algorithm of compensation of the path of tool that has showed promising results, see the Figure 10, for the conformed without matrix in cold.

Another of the activities of the project has been the manufacture of pieces demostrador of the technology for the sector. In the Figure 11 shows a piece realizar in Inconel 718. It treats of a subcomponente of an arriostramiento situated in the low part of the engine. The conformed incremental also allows to tackle the manufacture of the components of tube with geometries more complex like the showed in the Figure 12.

Manufacture of envolventes architectural and ornamental elements

The employment of envolventes architectural of innovative design so much by aesthetic reasons as of functionality (thermal sensors conditioning of the building, renewal of the façade…) is an increasingly recurrent option under construction. The majority of the times the envolvente is exclusive for each building and composes of crowd of elements that present designs very miscellaneous or even only. Therefore, the conformed incremental can be a very appropriate technology for the envolventes that present elements of sheet. The Figure 13 sample an envolvente metallic realizar in collaboration with Alpha Art.

In addition to the envolventes, the conformed incremental can be also of utility in the sector of the construction to manufacture ornamental elements so much of external as of interiors. The Figure 14 and the Figure 15 show a pair of examples of this type of applications. The technology can apply equally to sheet drilled and to materials no metallic like the thermoplastic.

Conclusions

The current industrial situation demands a greater competitiveness in the manufactura of the products, what achieves in a lot of cases with a change disruptivo of the manufacture by means of new processes. The conformed incremental of metallic sheet gathers the suitable characteristics to cover a space that to date is not resolved: the obtaining of pieces prototype and short series with a high degree of detail and in a time reduced. Obviously, when a company poses include the technology between his productive processes results indispensable a previous analysis of the application or applications considered. Like sucede with any new technology of production, a deep knowledge of the process to define the suitable parameters is the key so that the final result was the wished.

Tecnalia has identified the potential of the conformed incremental for some pertaining components to the aeronautical sector component manufacturing sector component manufacturing sectors, white line and construction, but is evident that exist a lot of more. The final aim is to support to the companies and transfer the technology by means of:

- Develop of knowledge of specific process for each case (new geometries, new materials, parameters of process…)

- Design and tuned of installations of conformed incremental

- Tuned of the process and manufacture at first pieces

- Development of specific auxiliary equipment (tools, software, useful of tie up…)

- Studies of feasibility of the process