This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

Desarrollo de nuevos SMC de altas prestaciones mecánicas (parte 2)Development of new SMC's high performance mechanical (part 2)

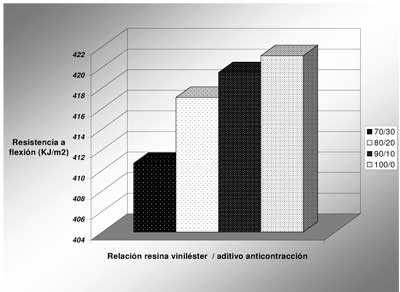

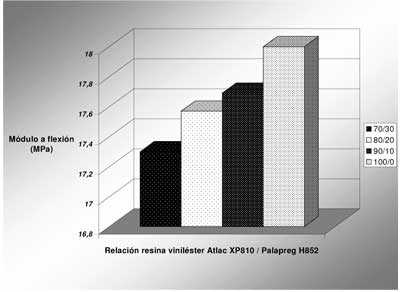

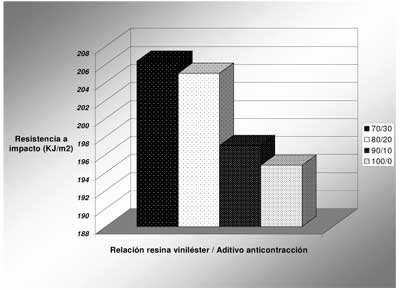

In the formulations developed changed the relationship resin vinylester thermoplastic additive anticontracción studying the following proportions: 70/30, 80/20 and 90/10 and 100/0

The results of the mechanical characterization after the compression hot 150 ° - 160 ° C in 180 s. cycles and a provision sandwich (woven into the view faces and mat inside) of the 2 layers of SMC used for mold filling you can see in the following graphs (Charpy impact test and essay of) (inflection).

The influence of the thermoplastic additive has been demonstrated after the characterization of the mechanical, and set the best value in proportion; 80 resin/20 additive thermoplastic for adequate benefits to impact and bending.

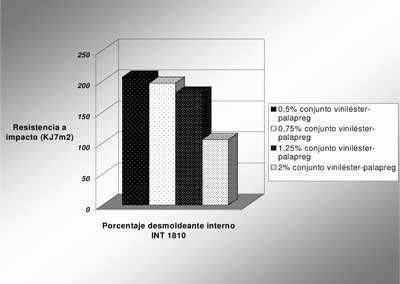

In keeping with the basis of the initial formulation, analysed four formulations more in which varied the percentage of the rusting internal INT used 1810, with respect to the weight set total resin vinylester Atlac XP810-Palapreg H852 (0.5, 0.75, 1.25 and 2%) to observe the effect of the component within the formulation that, although essential, breaks the perfect crossover in the structure of the matrix.

The following table presents the formulation developed basis:

The results of the mechanical characterization after the compression hot 150 ° - 160 ° C in 180 s. cycles and a provision sandwich (woven into the view faces and mat inside) of the 2 layers of SMC used for mold filling you can see in the following graph (Charpy impact test):

The higher is the percentage of rusting internal worse are the mechanical performance of the prepreg but better is its anti-corrosion for what has sought a balance setting the optimal percentage of the rusting at 0.75 per cent for a suitable anti-corrosion.

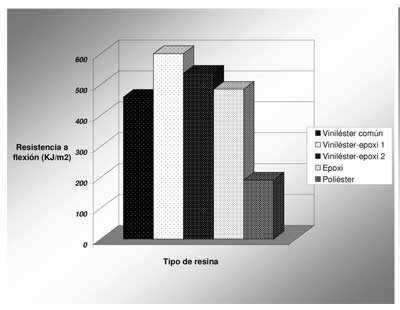

Once selected both reinforcing agent, the amount of the internal rusting which gives best performance mechanical, as well as the optimum of the additive proportion anticontracción, has defined the formulation "reference" to compare its performance front those who have the same composition but different polymer matrix.

With regard to the nature and the type of polymer matrices used are:

• The vinylester

• Vinylester - latest generation epoxy,

• Epoxy

• Polyester

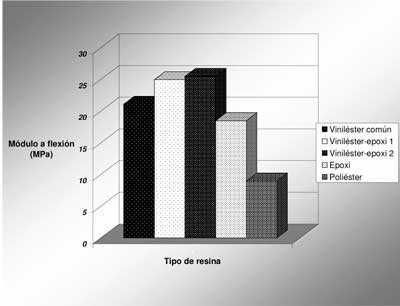

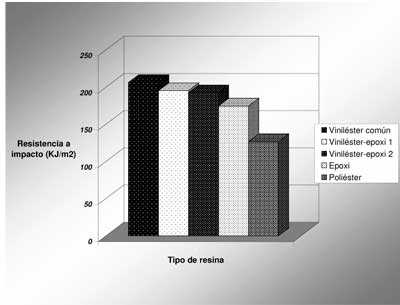

The results of the characterization may be seen in the following graphs (Charpy impact test) and bending test: