A new dimension of the steel

Although the folded of sheets of steel does not suppose any novelty, the conformed three-dimensional (3D) allows to create serpenteos, open compartments and forms more elaborated with an alone sheet of steel, deleting like this the need to solder. The trick consists in realizar the molding 3D without damage of the properties of the steels of high resistance, as well it has discovered the Swedish company Deform in collaboration with

When in 1907 founded Degerfors Ironingingworks, the current Deform, the steels of high resistance, the conformed three-dimensional of our days and even the welding still were for inventing. To give form to the sheets of steel employed hydraulics presses and rollers of flexión before joining them by means of rivets.

A century afterwards, Deform has desvelado the secrets of the ‘forming in hot' of the steel of high resistance without loss of the properties of east. Also it has developed a process for the design of an individual sheet of steel of high resistance with an elaborated outline, deleting in this way the need to solder several sheets.

“The market of the conformed 3D is growing, but requires still educate to designers and engineers on the possibility to conform in hot the steel of high resistance”, declares Conny Lundstedt, director of sales of the signature, that has topado with a lot of sceptics in the decade that carries in Deform. “They are used to descartar like impossible the conformed in hot of the qualities of steel of high resistance for thinking that when heating this to give him form go to destroy his properties, which, in reality, is not uncertain. Now well, we apply a process certified only in which we conform in hot but only destroy temporarily the properties of the steel, for afterwards restore them to the time that keep the form. There are not a lot of companies that are able to do this”.

According to Anders Bergstedt, technician of sales, the conformed with 3D operates of form quite direct. “It plants a cold or hot sheet between an upper mould and another inferior, designed by Deform, configuring of agreement to the design required”.

The preservation of the form and the properties of the steels of high resistance after the process of conformed, is what, to trial of Lundstedt, does of the offer of Deform something ‘only', apart from popular between the customers ‘of high category and high level of requirement' in the fields of defence, maritime, nuclear and of the oil and the gas.

Deform Considers that the use of an only sheet in place of several pieces soldered offers advantages so much to customers as to final users. No only they avoid the weak points around the areas soldered, but the customers save also time and money in works of welding. For the final users, the use combined of steels of high resistance and conformed 3D results often in a more robust product and light that, in the case of the vehicles, offers a greater hygiene to his occupants.

“One of the big challenges of the industry of our days is the fight by some sustainable surroundings and the reduction of the wastes”, asevera Lundstedt. “The weight is an essential factor in a lot of sectors, and in particular inside the transport and the minería, where each kilo that recorta to the weight of the vehicle can add to the load. When a product or vehicle weighs less, consumes less fuel and is more respectful with the environingingment. Besides, what less steel requires and less waste generates, more ecological will be the product”.

Although the advantages to combine steels of high resistance and conformed 3D are innumerable. Bergstedt resalta That the customers have to calculate the planned performance of the investment before putting hands to the work, since the moulds used for the configuration involve an initial cost. “Sometimes it does not have felt to invest in the mould. You have to determine if it goes to allow you save money, improve your product and optimise the level of protection of the same. You can not commission a piece of proof and see if it works. That is the only disadvantage of the conformacdo in 3D”.

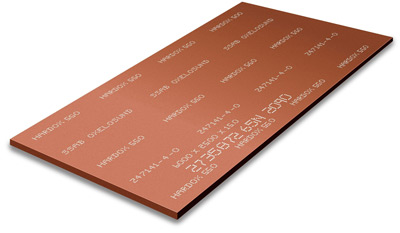

Deform Carries more than two decades working with the products of steel of SSAB. It employs Armox in many of his sheets of protection, whereas Weldox and Hardox use in other applications. Good part of the sheets of Deform are subjected to proof in surroundings of high requirement. His sheets of protection for minería find often under tanks and armoured vehicles and Weldox uses with frequency in the frame and the helmet of pressesure of the submarines. In case to detect a suspicious package in an airport, this will plant inside a camera of deflagración, with all probability manufactured from sheet of steel of high resistance conformed with 3D, evacuating afterwards for his detonation under conditions of hygiene.

“When they use thick sheets of steel to the carbon joined by welding, the containers weigh so much that result difficult to transport”, explains Lundstedt. “At present the containers can elaborate with steel Weldox temperate and revenido of three-dimensional forming in hot. The two semiesferas manufacture of an alone piece, without welding any. This method, joined to the use of steel Weldox, allows to the designers diminish in two thirds the thickness of the camera without loss any of resistance, what results in a new container lighter and easy to transport”.

To Deform, the collaboration with SSAB has worked him very well and trust can strengthen it even more in the future. “They have steels of first quality and enjoy of an excellent reputation to international level. On our part, we are expert in the forming by 3D to his steels of high resistance. At the same time we benefit us to a large extent of his global and excellent network support technical”, concludes Lundstedt.