Lapeyra & Taltavull: new generation of facilities at Equiplast 2005

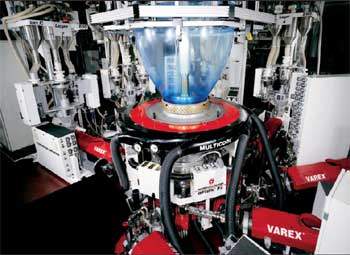

The new head of blown patented Maxicone is very suitable for use with wide and complex barrier film for film poliolefínico of several layers. Thanks to its compact design and system tapered Distributor, patented, is guaranteed with five or seven layers, minimum volumes of melt and minimal pressure loss. This greatly reduces the time spent in the mass fused at the head blowing and the time required for a change in the installation of blown film product. Reductions of up to 80 percent of the time of change are achieved.

A key aspect to achieve maximum production yields is the effective cooling of the bubble of film. With the cooling of double-decker Multicool D ring, the installation of five layers has one of the most effective systems for external cooling, that currently exists in the market.

The new basket brusher Variocage ensures accurate guidance of band with minimum tolerances for the width and convinces thanks to its robustness, stable construction and little need of maintenance. Thanks to the continuous regulation of the diameter, film can be measured up to a maximum width of 1600 mm. A flat installation extremely long and thus uniform cooling of the bubble of film, are the advantages of the new reversible shot Multinip.

The new Filmatic S winder is equipped as standard with an automatic decrease in tension of the band and the presora strength, adapted to the diameter of the coil.

The management and control of the individual components of the installation of VAREX blown film is through the new column of command Procontrol TS, where the operator made all the introductions through a touch screen.

Short resetting times due to a compact design

This time of extremely short change is achieved thanks to the very compact construction. Compared with earlier systems, the size of the Maxicone has been reduced by almost half. The head, which is equipped with the patented conical distribution system, has the smallest melt volume of all systems in the market.

As a result, this brings the following advantages:

- Very short change product and rinse times

- Long life of production (useful life)

- Lower pressure drop of the flow of the molten mass combined with a high-performance

- Excellent basic tolerances

- Very good perspective of the film

In the technological centre of extrusion in Lengerich, which has been renovated, is available to customers an installation of extrusion for the blown film Varex of 7 layers, with a head Maxicone, for testing.

The system Optifil

The system of automatic regulation of the profiles of W & H works based on the principle of a relationship between the temperature of the molten mass or the film out of the slot nozzle cooling is and of the tolerances of the film. More than 90 percent of all the influences on tolerances due to thermal inhomogeneities. This brought as a result of influence in local temperature of the melt and mix her using the now famous OPTIFIL P.

The new line of three-layer Varex supplied to "Aspla – Plásticos Españoles", in Torrelavega at the beginning of the year, also the system of automatic regulation of profiles Optifil P n ° 555.

Aspla - Plastics Spanish, a leading international company in the manufacture of industrial films, hygiene films, as well as films for food products, operates under the banner of the Armando Alvarez group. Client from W & H for long years, has a number of lines of extrusion blow from W & H with Optifil P systems and several flexographic printers.

Around the world "the Optifil P film" has become a synonym for high quality film. Since the W & H introduced in 1988 the prototype, the Optifil P has been provided in all continents and operates successfully under very different peripheral conditions. It is not exclusively facilities in new lines, it is also an ideal solution for the subsequent equipment of existing blowers heads or machines with automatic cooling Optifil P2K ring.

Optifil P2K represents a later extension of lines of film blown with a modern system of regulation of the profile without involving mechanical modifications of the blower header. The software used is identical to the accredited lines equipped with Optifil P type.

Today the use of automatic regulation of profiles systems in facilities for the blowing of movies of three layers, layers five and seven layers is standard. There are good reasons for this: to achieve a significant improvement of the quality and offers significant advantages in cost. After having sold more than 555 Optifil P systems on a global scale, Windmöller & Hölscher strengthens as a leader in systems for automatic regulation of the profiles in facilities for the blowing of films.

Nostic Air Cage guarantees quality film

Filmex: encapsulated innovator of the edge reduces manufacturing costs

Of course, the encapsulation of the edge with the installation of Filmex cast film extrusion is also possible with barrier film production.

Despite the extremely high production for PP speed, is reached a very high quality of film, made from the smooth progress of cylinder cooling ("chill-roll") through pretreatment of film to the sensitive winding through the Filmatic M winderall the components of the installation are in perfect harmony.

W & H gets another reduction in the rate of decline in the installation of extrusion of film Filmex cast through the regulation of row again development Profile booster. With this innovative in the row slot regulation is strongly reduce the Filmex boot times and thus are also reduced the rate of decline.

Easy Set: the technical innovation of the year 2005 in the flexographic printing

Heliostar G: new series of rotogravure printers

The Heliostar G series rotogravure printers can be equipped with up to 12 entintadores groups and are available in widths of printing that can range from 900 to 1700 mm.

The Heliostar GE and Helikostar GL models offer different technical solutions for changes between works: the conception of the GL Heliostar change is based on the most modern technique of pluggable carts, a plug-in cart for the change of system of inking and printing cylinders is available per Inker groupwhich remains among the Inker during printing. The basic concept behind this machine is the system of automatic change of orders Ecoplus. This allows a change of order very fast and simple, since the change of the cylinder of printing or the cylinder and the trays of ink is carried out fully automatically in all entintadores groups at the same time.