With the software of

Gestamp And AutoForm, together to a robust production

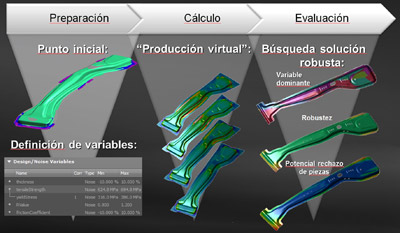

The simulation does indispensable in the study of these processes and no longer only is necessary an alone simulation but it has to analyse a group of them to guarantee the results taking into account the variability of the properties of the material, of the thickness of the sheet or of the conditions of the troquel during the production of the piece.

The use of the software of AutoForm improves the reliability in the planning and reduces the number of essays of coin and the time of his tuned. Like result obtain pieces with greater quality and designs of matrices that can produce with maximum confidence; besides, the time of presses and the ratios of defective piece reduce substantially.

In the year 2005 appear AutoForm-Sigma, only module in the market, specialised in analysing and improve the robustness of pieces of metallic sheet and his processes. With AutoForm-Sigma the process of manufacture is more efficient and stable reaching the aims of quality wished.

In the start of the year 2012 Gestamp Global Tooling and AutoForm undertake a project colaborativo with the end to implement the solution AutoForm-Sigma in the daily work of the troquelerías of the group. Of this form Gestamp Global Tooling bet by the innovation to achieve greater competitiveness and increase the profitability of his processes, trying reduce the times of unemployed machine and of adjust of the tool in addition to minimising the cycles of compensation of the troquel to achieve the quality wished of the piece.

The project initiates with a small learning of AutoForm-Sigma to the experts in simulation and processes of Gestamp Global Tooling. Once finalised the learning, the users of AutoForm of this division of Gestamp can verify the advantages of the use of AutoForm-Sigma in any of the pieces that are working, overcoat in pieces of aluminium, material increasingly common in the production of pieces of metallic sheet.

AutoForm-Sigma No only contributes the possibility to increase the robustness of the process but it also helps in the taking of decisions. The tendency to use formats of sheet smaller to reduce costs of material can cause, in some cases, defects of piece and unsteadiness of the production. This at the end comports an increase of costs of production of troquel. This example is a problematic typical that finds Gestamp Global Tooling daily. Thanks to his long experience in troquelería, the experts of Gestamp know which problems causes this reduction of format of sheet but in occasions need no only an opinion but this go accompanied of a quantitative result to be able to take a decision. By means of the results Cp and Cpk that provides AutoForm-Sigma, this possible defect of the piece is easily tangible and the user of this solution of AutoForm has of greater arguments for rebatir a decision to the final customer.

After a year of cooperation between both companies, where AutoForm has supported and creame this implementation of the product, Gestamp Global Tooling has purchased the solution AutoForm-Sigma and follows working in the improvement and increase of robustness of his processes.

According to Pablo Pascual, director of Engineering of Gestamp Global Tooling: “the utilisation of AutoForm-Sigma has allowed us have a tool of able work to detect the most influential parameter inside the process of filling allowing us act of fast and effective form in the election of the suitable process. In a second place, the utilisation of AutoForm-Sigma has allowed us in unstable pieces, because of his own configuration (DP, Aluminium) or his conception, define a stable process of filling to ensure a correct industrialisation in the OEMS or the own plants of manufacture of Gestamp”.