Cutting by stream of water

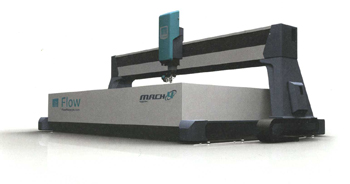

The cut by stream of water is a process of mechanical type by means of which achieves cut a material, doing hit on this a stream of water to big speed that produces the finishing wished. Today already it is an usual resource to the hour to mechanise pieces, simple and at the same time very complex. It is a very versatile tool whose application is extensible to practically all the works of the industry, entered by Flow International in 1980, of a today rudimentary way.

The procedure of cut in cold is sued in all the applications in which the material can not remain affected by the heat. Descartamos The cut with circular saw, saw of strip, tool of calar and penetrate. Of course the cut by laser or plasma. The first step is the design of the piece, with the timely program of computer-aided design (CAD), by means of which assign the measures of the object, the thickness and the type of material to cut. Designed the piece, links to the particular program of the machine of cut by stream of water. After storing the program in the database, by means of the computer of the machine of cutting looks for the archive saved. It decides the type of cutting that wishes obtain, from the grossest to the most clear-cut, but the edges always will be clean and without imperfections, according to the price that was had to pay the customer. It adjusts and fixed the piece to cut, that can be a rest of mechanised that wish rentabilizar.

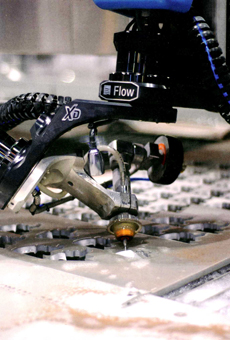

The correct location of the pieces to cut will allow, in the case of machines with multiple cabezales of cut, work in parallel and speed up of this form the process of cut, being able to work with different commissions of simultaneous form. From this moment proceeds to the cut of the piece and the machine takes the control of the operation. It exists the possibility to interrupt the process to check if all goes correct. The machine initiates the cut to the end in a process contínuo that finishes with an excellent finishing of the piece to mechanise.

The filter of water

His diameter oscillates between 0,08 and 0,45 mm, whereby goes out a mix of water and abrasive, launched to a pressesure until 4.000 bars, or more, able to cut any type of material. Of the filter by which goes out the stream depends the technical feasibility of the operation as if the stream is conical, with tendency to an increase of the diameter, loses power of cut, precision and quality. The pressesure is contributed by a gifted bomb with an intensificador of ultrapresión, with a maximum of at least until 4.000 bars of pressesure. The water goes out to the speed of Mach 4c. 50 HP are sufficient for the bomb.

Depending of the object of work exists the option to use lower pressesure, on some 2.000 bars, or even work without the abrasive. But this uses with materials of little hardness (plastic) that do not need of the abrasive to be cut. Sometimes it does not interest to cut but only mark the piece or print a metallic sign. Generally it works to very high pressesures even in occasions in that it would not do fault but like this speeds up the process, attaining greater rapidity of cutting. The cut can go from minutes to hours. The speed of cut is of maximum importance and will depend on factors like the pressesure of the bomb, the capacity of the intensificador, the diameter of the nozzle, the quantity and quality of the abrasive and of the thickness of the piece. The maximum speed of exit of the liquid has a maximum of 1.000 m/s roughly.

A machine of Flow, of cut by water. This signature entered this system in 1980, of a today rudimentary way.

The abrasive (mix of clay and glass) adds intensity of cut, because the water to alone can not seccionar material very hard. The thickness of the piece to cut will have to have 5 mm like minimum, so that this procedure was profitable, and a maximum of 200 mm. With soft materials there is not limit of thickness: with water to 4000 bars and abrasive can cut cork of 2m of thickness. The hard materials are: steels toughened, titanium, alloys of nickel, ceramic.

Regarding pumps, there are them of all the powers in the market. We quote one: bomb of piston of ultra high pressesure for cut by water; maximum psi 90.000 (6.200 bars), 50 HP (37 kW).

The cut by plasma is faster that the cut by water but heats the material. Photo Vanad.

The method can employ , without cut, to prepare surfaces, the cleaning of ships, trucks and in the aerospace industry. It does not generate contaminantes neither comports superficial oxidation. Besides, the generation of shaving is not a problem. The machine has of a container to receive the stream of water and the material deleted. The abrasive used can recycle for reutilizarlo. This process does not toughen the material neither the shapeless by what, in this sense, is more useful that the laser, the oxicorte or the plasma. Likewise, to the not having tools of cutting does not exist the wear of the same. It is a process without exfoliation neither desgarros, apt to mechanise profiles intricados. And there are not residual tensions due to the fact that the process does not generate efforts of cutting. Neither it generates gases.

The mechanised can realizar it the same engineer that has designed the piece since it does not require a gross manual work but simply program the machine, situate the piece and collect it once mechanised. In comparison with the laser, the stream of water allows to cut greater thicknesses. Regarding speed of cutting the plasma is faster that the cut by water.

In the office does fault a PC for the design of the piece and, in the workshop, a PC of workshop where receive the orders of the PC of office. Here it is where executes the order of work directly on the machine of cut by water. It needs refrigeration of the mechanical system that realizar the cut, to avoid the overheating. A small bomb moves the refrigerante. The deposit of abrasive does not create problems. For the water does fault a descalcificador, to avoid the obstruction of pipes.