This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

Poderosos servomotores para prensasTheir demand has increased in recent years

Powerful servo motor to presses

Jean-Luc Montamat, Vice President of business development of GE Fanuc Automation Europe (General Electric and Fanuc Ltd. company), describes the new generation of engines and its advantages, including its high degree of flexibility and precision. The most recent developments in presses are representative of the trend towards the use of systems servo where, previously, only the hydraulic systems were conceivable. This is possible due to the availability of large systems I servo AC developed by Fanuc in recent years. Digital servo control system offers greater accuracy and efficiency.

Jean-Luc Montamat: "the large servo motors of GE Fanuc offer the reliability required to deal with the effort for the presses." These robust engines can operate continuously 24 hours. "Support without any problem the frequent accelerations, decelerations and vibration characteristics of the pressing process, and guarantee maximum precision and repeatability."

Ten years ago, several Japanese manufacturers began to use large Fanuc servo systems in their new presses. Since then the acceptance of these machines has been growing gradually. The year 2001 was a milestone in this development: GE Fanuc introduced a servo motor of large size with a nominal capacity of 110kW. This encouraged manufacturers and did grow demand for large servo motors. FANUC developed two models with nominal powers of 200kW and 250kW, called Alpha 2000 and 3000 Alpha (HV) is, respectively, that have a power output of 400/450kW, a maximum torque of 3800/5500Nm at speeds of rotation of up 2000rpm. To get even more power, two or three engines can be used in tandem, or synchronous mode.

In these servo motors, designers have optimized the shape of the magnetic circuit by FEM (finite element method) analysis, thus improving the characteristics of the couple and the efficiency of the engine. In addition, the special form of the large servo motor rotor increases mechanical stability under the centrifugal force and against mechanical vibrations. Of GE Fanuc large servo motors offer the reliability necessary to counteract the effort for the presses. These robust engines can be used 24 hours, being able to cope with the frequent accelerations, decelerations and strong vibrations of the operations of pressing without any problem.

With energy saving function

GE Fanuc has been integrated into their large servo motors function which helps the user to save energy. This function returns the power regenerated in the slowing down of the servo motor to the power supply network, rather than dissipate it through resistors. For example consider a press servo of the class of 100 tons (equipped with a servo motor Alpha 1000 (HV) is) and a functioning of 8 hours per day for 260 days a year. At a cost of 0.08 EUR/kWh, annual electricity savings reaches almost 8000 euros.

Recovered electrical energy can be directly reused in the press. To ensure an effective reuse, other machines connected to the same transformer must also use this energy. If they cannot use all of the recovered energy, remaining energy flows to the external feeding system. In addition to energy savings, the regeneration of electric current system has the advantage that it is not necessary to use resistors, which occupy space and generate heat.

Reliable power supply

When you install a press servo in a deformation of sheet metal plant, one of the biggest concerns is normally necessary food for the system. For large systems in GE Fanuc servo, the minimum voltage is 372V (93 per cent of 400V) if the servo motor is to produce maximum torque. The operator can take the following measures to ensure that you get more than 372V of the power supply. The use of low impedance power cords, and cables short of large section connected to the power supply of the servo unit help to prevent voltage drops. In addition, the systems servo GE Fanuc 400V AC can operate with voltages in the range of 400V up to 480V AC. If a stream of 480V AC can be applied by raising tension with transformers, a drop in voltage up 108V is admissible (= 480V - 372V). Another measure is to store the energy regenerated in capacitors. This option is available when you need a high output torque to accelerate the servomotor and shaping the piece. The capacitors function as an "electric steering wheel".

Presses servo require a large electric power for short periods to speed the servo motor and shaping the piece. However, while the servo motor is moving at constant speed, the electrical power required is very small. Therefore, a full cycle of pressing needs the same amount of power, or even lower, than the conventional mechanical presses with the same force of pressing.

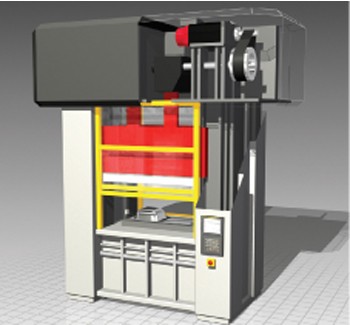

Power for large presses: new servomotors 2000 Alpha and Alpha 3000 (HV) is offering a maximum output of 400/450kW power. The maximum rotational speed is 2000rpm.

A strong combination

After the first successes of the applications of the servo presses, increased demand for more power from pressing. Currently requires forces that not even a "great servomotor" can be achieved by itself only. For this reason, Fanuc has developed a technology to allow a single servo motor is powered by multiple amplifiers servo. Multiple isolated windings, each of which is connected to an amplifier, are aligned in the engine. This allows the use of amplifiers standard servo for each winding, getting a reduction of costs, high reliability and easy maintenance.

It has also developed a technique to power a machine with several servo axis, in which case a single engine may not generate the necessary torque to the press. Loads of different servo motors can vary. Software digital Fanuc servo technology reduces interference between the engines, caused by different loads.

Angle and movement control

GE Fanuc CNC technology provides two different controls of movement. "Control of the angle", which regulates the position of the wheel of transmission, and the "motion control", which regulates the position of the car.

The angle control is used for continuous pressing cycles, which monitors the positions of the servo motor and wheel transmission. In this mode of operation, the upper and lower dead position are fixed. In order to maintain accuracy, the CNC records current dead position in each cycle of pressing through a linear sensor in the car. It then controls a unit of height adjustment. This provides high productivity, because servo-motor and transmission wheel does not need to invest your address.

The control of the Movement attaches a high precision to the pressing process. The position is also controlled via the linear rule in the cart. The engine is moved so that you can find the correct position of the cursor detected linear rule. This procedure allows the servo motor to rotate in the opposite direction. The top and bottom dead positions can be interchanged.

The ability to directly control "big servos" allows an optimized pressing procedure. These servo motors offer also many advantages for stamping lines.

Related Companies or Entities