ABB, goes beyond the traditional download of the injection machine at Equiplast 2005

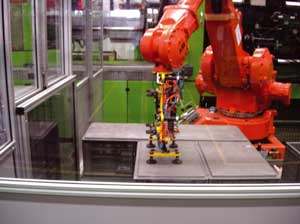

Based on detailed above, ABB has been roboticized a new facility in which the task of unloading of injected parts is only one of the many productive cell.

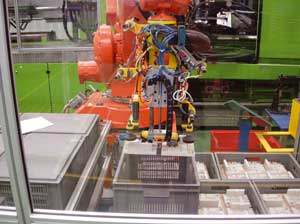

The installation in question is composed of a run by a robot ABB model IRB4400 Engel of 350 tonnes injection machine. The pieces are injected into a mold of four cavities and, as a prelude to the injection process, place a screw in each of the cavities.

After the download of the fuel transfer, the pieces should be placed in plastic crates, piling six pieces by floor and placing a cardboard separator between each floor.

After the robotization of the entire process, an operator places a pallet with inverted plastic boxes. From that moment the robot carries out a series of tasks that allow 75 minutes later, we have at the point of exit from the cell of work cited pallet loaded with perfectly injected parts boxes.

To do this the robot is responsible for:

- Catch and flip the plastic box in which shall be deposited with the injected parts.

- Place the box in the corresponding position of palletizing.

- Feed of inserts (screws) to the injection machine prior to the injection process.

- Download the injection machine.

- Place the pieces injected into the interior of the plastic box.

- Place separator cardboard on each layer of pieces.

All tasks are performed with a single clip of manipulation. The design and conception of that element allows the needs of different and varied processes existing in the productive cell manipulation.

The end result is a productive cell in which, during the phase of injection, the robot carries out various additional tasks, managing to increase the performance of the teams of the workstation, and one of greater autonomy of the productive cell.