Siemens NX 9 offers until 5 times more productivity in the development of products in all the sectors

The last version of the software NX of

The introduction of the technology of design of fourth generation (4GD) will improve the productivity in the design of big assemblings and the software NX Realize Shape offers a new set of tools of design improvised with an unprecedented integration in the development of the product. NX 9 also includes the integration PLM through the surroundings of work Activate Workspace of Siemens, as well as multiple improvements in the integrated solutions CAD/CAM/FALLS. The improvements in NX 9 have been implemented to create value resolving common questions in multiple industries like the automotive sector, the aerospace, the nautics construction, the products of consumption or the machinery, among others.

“NX 9 represents an important step forward for Siemens, for our customers and for the development of product in general”, ensures Jim Rusk, vice-president senior of Siemens Industry Software. “With new significant advances like synchronous technology 2D, 4GD and NX Realize Shape are offering to our customers a flexibility in the unprecedented design, what at the same time increases of significant form his productivity in the development of product. And to take advantage of our successful solution Activate Workspace, are improving the experience of user of high definition so that it help to our customers to adopt decisions more intelligent that result in better products.”

Synchronous technology 2D, a step forward to the industrial intelligence

Whereas the modelling 3D is the method of design of product preferred all over the world, the outlines in 2D and the data of product in 2D – in a wide variety of digital formats- still use in practically all the industries and in some appearances of the development of product. Unfortunately, because of structures of incompatible data and a technology CAD inconsistente, work with these archives in 2D can result tedious and slow. Synchronous technology 2D deletes these problems when adding intelligence to the data in 2D without need of conversion, allowing to the users edit intuitivamente archives multi-CAD 2D until five faster times. This can be of particular use for industries like the automotive sector, the aerospace, the machinery and others with big quantities of data of product in 2D inherited.

“Synchronous technology 2D of Siemens is a tool 2D of new generation that resolves many of the lacks of the outlines and drawings”, explains Chad Jackson, main analyst of Lifecycle Insights, a centre of investigation and quality consultancy leader in PLM. “It understands the inherent geometrical relations in the outlines in 2D and applies hypothesis controlled by the user in the moment of change to allow intelligent modifications. Also it applies these suppositions of local form in place to do it to global level to guarantee a better performance.”

Unprecedented improvements

The new NX Realize Shape offered in NX 9 provides some only surroundings of free design to generate products with forms very stylized or complex surfaces. It is the only solution of the industry that integrates the most advanced tools, flexible and easy to use to realizar designs of free form with a package of software CAD/CAM/FALLS leader. Like result, the companies that produce a big variety of products of consumption –as well as the ones of the aerospace industry, medical and marine– can reduce the time of development of product deleting multiple steps associated with the use of separate tools for the design of free form and development of the engineering.

Cientos Of additional improvements in NX 9 tackle all and each one of the appearances CAD, CAM and FALLS. The introduction of 4GD, a new paradigm of design and management of data that allows to obtain versatile and efficient methods for the collaboration and the design in context, accelerates the development on a large scale of complex products that contain million components. The incorporation of Activate Workspace 2.0, the new and innovative interface of the software Teamcenter of Siemens, allows to the users of NX 9 find quickly notable information, pieces, tasks, flows of work, requirements and specifications- even from multiple sources of external data.

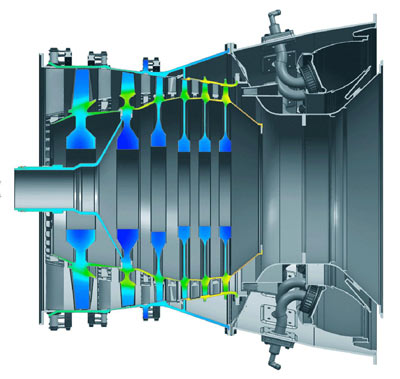

The new tools of NX FALLS improve the thermal sensors simulation of motors of aeroplanes, reducing in 75% the necessary time to configure the conditions of outline more complex. A new solver thermal sensors NX FALLS in parallel provides a better performance in the models on a large scale achieving better results. The improvements in the software NX Nastran, the main editor of UGLY solutions for the computational performance, the precision and escalabilidad, allow to reduce to the half the times of simulations of noises, vibration and NVH.

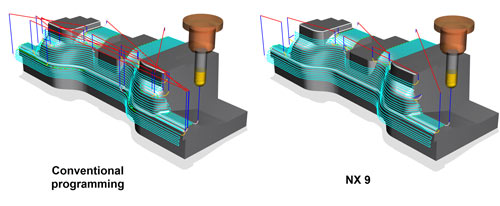

The new capacities of NX for manufacture provide a control of the programming CAM and CMM faster and flexible. For the mechanised of matrices and moulds, the new capacity of management of the region of cut provides to the user a graphic interaction for a more efficient programming, until 40% faster in some complex pieces, as well as a more precise control on the strategies of mechanised. The new capacity of programming of multiple pieces allows to the programmers reutilizar sequences of mechanised with any number of similar pieces in a configuration. For example, a configuration with six identical pieces can be programmed until four faster times. The new MRL Connect for NX, connects NX CAM directly with the Manufacturing Resource Library (MRL) in Teamcenter, what gives to the easy programmers access to a library shared of standard tools, accessories and staff. The functionalities of CMM Inspection Programming have expanded further of the solids to bear the sheet metal pieces, offering to the manufacturers of the aerospace industry and defence, electronics equipment dealers equipment dealers of high technology and to the industries of automotive sector, a solution of programming highly automated.