Helmut Roegele In the K of the hand of Illig, Buss and Kentya

Illig (Hall 3, To52)

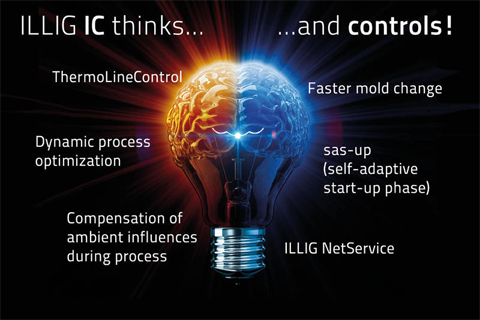

In the K of this year, Illig presents the termoconformado of the future with the machines roll-fed instrumented with the innovative IC-Technology. The machines instrumented with the 'Concept Intelligent Control Illig' appear marked with the addition 'IC'. This new concept elevates the termoconformado to a new level: the optimisation of the dynamic process, one of the elements of this concept, allows for the first time use the optimum of a line of termoconformado, provided by the technology of machines of nowadays, that is to say the units of servomotor employ in all the sections of the machine, quickly and requiring a minimum operative effort.

In the stand present , in conditions of production, two lines of termoconformado roll-fed automatic with machines and moulds of the series RDM-K and RDKP, instrumented with the new technology of IC. The machines RDM-K are designed specifically for the production in series of glasses of different forms and sizes with thermoplastic material. The termoconformadoras roll-fed of the series RDKP produce trays and packages with hinges, that use for example, for the protection of alimentary products during the transport and presentation in the shelf of the supermarket. In the stand will produce glasses of APET in a machine 54K IC-RDM with an area of conformed of 520 x 300 mm². The machine is instrumented with a mould of 18 cavities, that is to say, can produce more than 50.000 glasses by hour. On the other hand, the machine 72 IC-RDKP produces containers with hinges in PP (maximum area of 756x535 mm²) in a mould of six cavities.

Buss Compounding (Hall 16, To59)

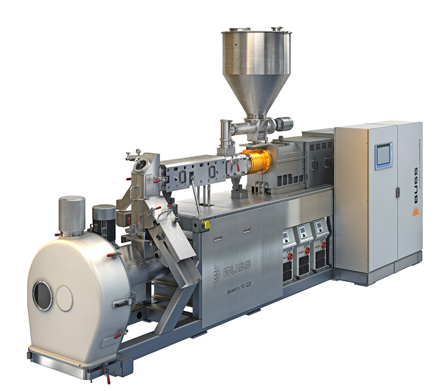

The quantec G3 incorporates twelve years of knowledges and experience of the technology 4-flight of Buss. His mechanical and technological characteristics key are a longer section of processes, now expanded to 14 L / D (L = length of the section of process, D = diameter of the husillo) —for a better mix and greater performance— and the biggest diameter of the zone of entrance. The soft transition to the small diameter of the zone of the mezcladores/amasadores sees facilitated by the coatings conical in accordance with the specific requirements of the product. Besides, the husillo external to diameter of the axis has increased to 1,62. This increases the volume of available performance to a constant speed.

A fundamental characteristic of the quantec G3, regarding the quality of the product, is the design patented of the fins of his husillo. The geometry of the surface, of a free form optimised, ensures a space of constant cutting between the fins and the bolts of kneaded –especially the length of the fin of the husillo–. This geometry plays a decisive paper, in particular for a kneaded and a soft mix, by means of the maintenance of the strength of constant cutting on the product and deleting in this way any risk of local overheating.

Kentya (Hall 17, To79)

Said lines of extrusion are having a lot of success by his competitive price, simple handle and big flexibility with regard to the needs of the customer, for treating of an own mark. All this without incorporating equipment of crystallisation.