Robotic solutions for transformers of plastic

In Düsseldorf,

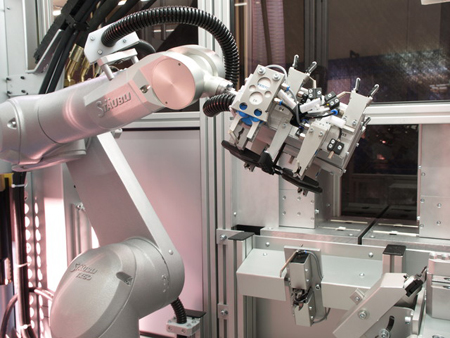

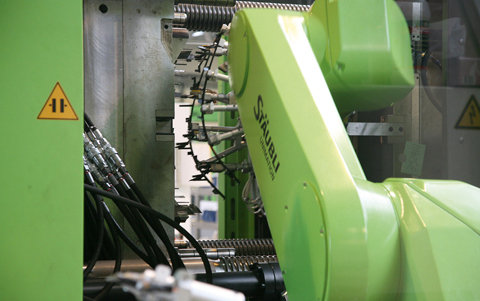

In narrow collaboration with transformers of plastic and manufacturers of machinery, Stäubli has developed many of the robots and tools of software that expose . Of this way offers the perfect solution for the automation of plants of injection of plastic, independently that it use in surroundings of adverse production or in white room. The series of robots TX and RX, specific for plastic, are perfect for diverse operations like download of pieces, mechanised complete of pieces moldeadas by injection, decoration and/or labeling in mould; so much for the use of the own machine inyectora as for numerous additional applications.

The fast robots Stäubli of six axles, exert increasingly sequential tasks, as for example deburring, verification, cutting, encolado, setting or packaging. They fulfil all the requirements to realizar these functions, thanks to his structure and precision, and to his dynamic elements. When loading and download machines of injection, reduces to the minimum the opening times of mould. The series of robots plastics can manipulate loads of until 34 kilos. It covers from the compact TX40 plastics, going through the classes TX60 and TX90 of intermediate weight until the RX160 plastics, with his scope of two metres.

Three new special cinematic solutions

The Fast Picker TP80, with more than 200 picks by minute, is recommended for all the applications of pick & place in the industry of the plastic. The robot RX170 hsm, instead, has been designed to mechanise material of plastic of fast and simple form. It has substituted the sixth axis in this robot, by an electrohusillo, that thanks to his scope, allows to mechanise big pieces of precise form. The combination with a linear axis allows to realizar without difficulties the mechanised of pieces of plastic of several metres of length.

Programming: everything is possible

The developers of software, have created the application VALplast so that, so much the operarios of plant like the integradores of systems, can benefit of the capacities of the robot without need to have any special knowledge. This interface speeds up extraordinarily the programming basing in essential elements already predefinidos. Besides, thanks to the solution of software uniVAL drive, Stäubli offers to the manufacturers the option to operate the robots through the own system of control of the machine inyectora. It treats of an interface in real time that allows the integration of Scara and antropomórficos under control external.

In his stand, Stäubli Robotics shows how the solutions of automation for the industry of processing of plastic can be productive and profitable; Stäubli has of the suitable solution for a wide spectrum of sectors (automotive sector, aeronautical sector component manufacturing sector component manufacturing, aerospace, feeding, chemist, doctor and similar), where requires the automation in the transformation of the plastic.