Sumitomo (SHI) Demag Shows a technological jump in the injection

The visitor that approach to the stand of this company (represented by

With the Systec SP 280 (strength of closing of 280 t) Sumitomo (SHI) Demag presents a new type of machine, especially thought for the sector of the packaging. “SP” Are the initials of “Speed Performance”, which achieves by means of an accionamiento hybrid and specific modules. Besides, in combination with the platform Systec, what attains is a relation price-ideal performance. The model Systec SP is suitable when they require stable processes in the massive production of articles for the sector of the packs and packaging. An example will show in the K with the injection of containers of PP with capacity of 1,2 l and a process of IML. It uses a double mould and an injected of 84 g, in a cycle of 5,3 s. The extraction equipment equipment of the container decorated and the insertion of the label IML in the mould for the following cycle realizar simultaneously by means of an automatism of high speed developed by Sepro Robotique in collaboration with Machines Pagès. This new machine is ideal for those that do not need the model of high provision THE-Exis SP.

The manufacture of a screen multitáctil using a Systec 210 of 210 t of strength of closing puts of self-evident the experience of Sumitomo (SHI) Demag in cells of injection totally automated and the reliable production in a reliable process of innovative products. In the process, the functional plates of PET with fine metallic structure recubren by means of rociado with PMMA in the process of IML.

The narrow frame, also injected, decorates at the same time by means of IML with a finishing lacado in black. All the processes realizar in the cell, in conditions of clean room (ISO Class 7).

Although the most important part of all the process is the injection, the back steps that realizar out of the mould in a cycle of 40 s contribute to the quality of the piece and to his economic value.

Change of fast colour and new plastification

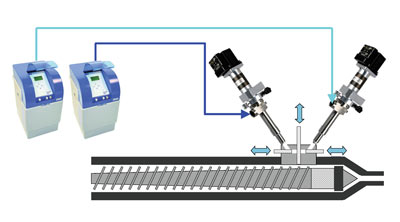

Sumitomo (SHI) Demag plastics Machinery Presents two new modules for the injection: activeColourChange, a system of dosage of pigments that reduces to the maximum the time of change of colour and the unit of plastification SL, that works without the usual zone of compressesion. The aim is to increase the efficiency by means of the combination of the length, energetic efficiency, availability and performance of the production.

With activeColourChange, Sumitomo (SHI) Demag has developed a new system of dosage of liquid pigment in which the pigment dosifica in a system closed directly to the zone of mixed loaded with mass melted. On the contrary that the pigmentation by means of masterbatch, for example, the zones of feeding and of compressesion remain totally free of pigment. It is thus that when it produces a change of colour, the zone of the husillo that has to clean is much shorter, which accelerates the process notably. The new system can be used until with five colours. The set up or turned off of the dosage is integrated in the control of the machine NC5 plus and is automated. So alone some cycles after the beginning of the pigmentation can obtain pieces coloreadas.

On the other hand, also stands out in this stand the system of plastification SL that distinguishes of the conventional systems by a husillo without zone of compressesion. The level of filled optimum regulates is determined by the properties of the material and the parameters of the process and the feeding of the material controls by means of a husillo dosificador. The material added melts exclusively by means of a supply of heat controlled through the warming of the cylinder of the husillo plastificador. One of his advantages is the homogeneity of the mass melted, without variations in the viscosity, which reduces the differences in the quality of the product because of a process without variations. Another of his advantages is the one who refers to the purity of the mass melted, something very important for example in the sector of the optical pieces.

The system SL is at present an option of the totally electrical machines of the series -EV, available in strengths of closing of 50 to 180 t.