New formulations with natural loads for the manufacture of pieces by rotomoldeo

The moldeo rotational or rotomoldeo is the process of transformation of the plastic employed to produce hollow pieces, in which plastic in dust or liquid pours inside a mould while it turns in two twinaxial axles. The plastic goes melting while it distributes and adheres in all the internal surface. Finally, the mould cools to allow the extraction equipment equipment of the piece finished. Said process characterises for allowing the obtaining of pieces with big superficial quality, good homogeneity of thicknesses and high mechanical properties. The moldeo rotational offers big freedom of design, as it offers the possibility to manufacture from small hollow pieces like toys (dolls, balls, caballitos), mannequins, pieces of luggage, buoys and other devices of flotation until pieces of big size like helmets of launches and canoes, tanks of fuel, industrial barrels of big size, containers and tanks of storage, among others.

To weigh that in the last years, the rotomoldeo has gone purchasing a greater technological maturity because of the innovations in equipment and technical of control incorporated, from the point of view of the materials, the process finds in a technological level more retarded that the rest of processes by the little or invalid availability of materials more sustainable with the environingingment, that on the one hand reduce the consumption of plastic and by another possess greater characteristic of biodegradabilidad and reciclabilidad.

With this end, Aiju, beside Ebrim and ULPG, are working jointly in look for of new alternatives for the obtaining of compound plastics for rotomoldeo, employing natural waste that on the one hand, help to minimise the quantity of plastic employed, when treating of a derivative product of the oil and no renewable and besides more expensive, and on the other hand give him an use to waste that up to now did not take advantage of or employed for other uses, like the incineration. In this work has employed the shell of almond like natural load.

Materials and experimental methods

Material

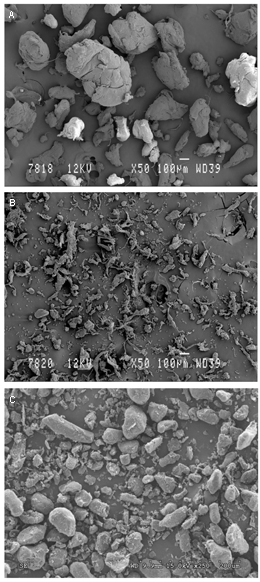

The shell of almond employed has been of the variety ‘marcona' and possesses an approximate density of 1.043 g/cm³. Also it has employed additive oxo-degradable, Addiflex HES, to induce to the degradation of the plastic matrix.

Experimental methods and equipment employed

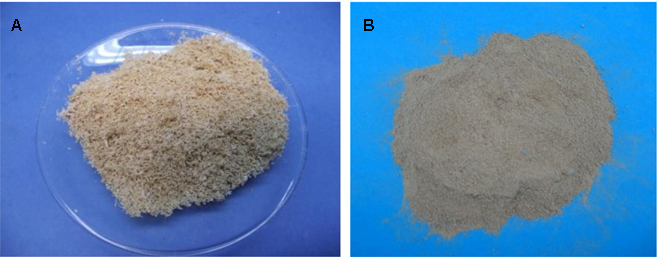

Appears 1: Photography of the shell of almond: to) triturada and b) dust.

The proofs of rotomoldeo have carried out in a small machine to scale laboratory. The mould employed has been a mould of aluminium, in shape of cube of dimensions 85x85x85 mm. The mechanical properties have determined from the probetas extracted of the pieces obtained by rotomoldeo. The results of the mechanical characterisation have obtained like the average of the values obtained of the characterisation of each one of the faces.

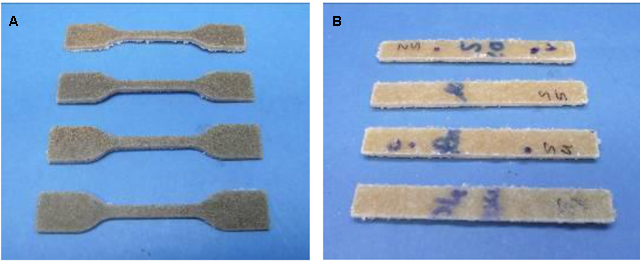

Have obtained two models of probetas normalised, ones in shape of halterio for the essays of traction and other rectangular for the essays of flexión and impact. In the Figure 3 include the two models of probetas obtained.

Results

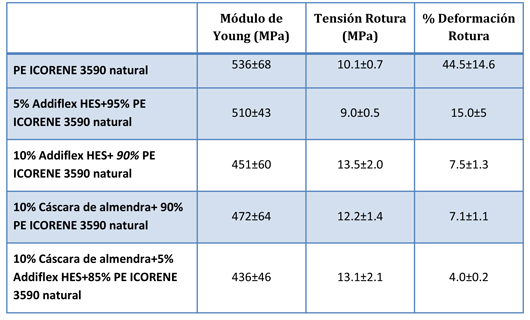

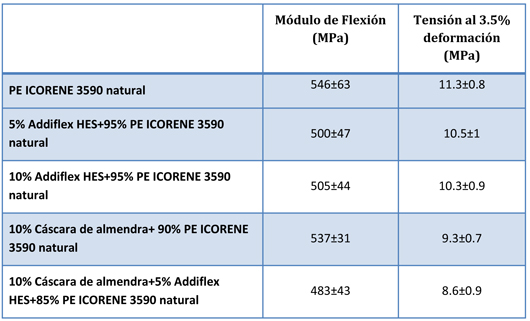

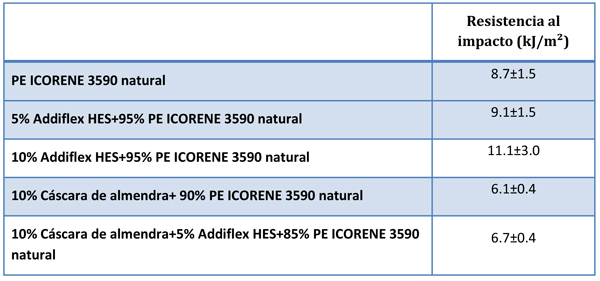

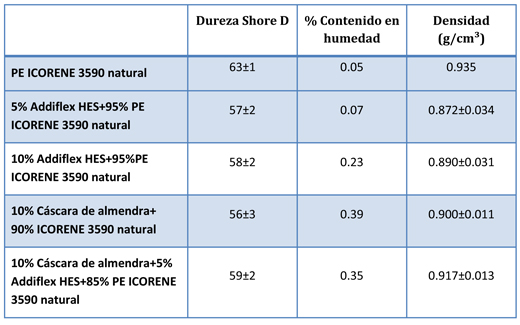

In the Table 1 and Table 2 show the results the mechanical properties of traction and flexión respectively of the different material rotomoldeados. The incorporation or increase of the percentage of additive oxo-degradable in the formulations, Addiflex HES, produces a decrease of the rigidity of the material.

Conclusions

From the results obtained of these preliminary proofs, extract the following conclusions:

- The incorporation or increase of the percentage of additive oxo-degradable in the formulations, produces a decrease of the rigidity of the material.

- The shell of almond acts like load, increasing the fragility of the material.

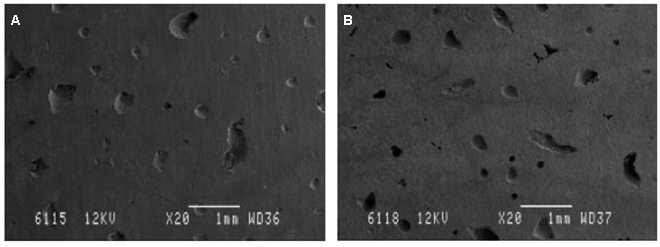

- The surface of the pieces obtained present intersticios (hollow) due to the fact that the process of rotomoldeo realizar without pressesures of compactación.

Next activities

Inside the study of the employment of natural fibres in the process of rotomoldeo, the next activities of the project will centre in realizar proofs with new natural waste (fibres celulósicas, fibre platanera, shell of walnut, etc.) as well as with mixes of biodegradable materials with natural waste. They will optimise and they will improve said formulations so as to be able to employ them in the process of rotomoldeo.

The activities developed in the present work have been possible thanks to the financials contributed by the Ivace (Valencian Institute of Business Competitiveness) and by the Ministry of Science and Innovation to the project whose reference is IMDEEA/2012/30 and IPT-2011-1894-420000, respectively.

To the Cooperative of Castilla, The Trencaora, by the free supply of the shell of almond.