The freedom it is necessary to live it with Arburg in the K 2013

The manufacturer of machines

“The fair K no only is the main world-wide fair of the plastic but for Arburg has been and is the perfect stage to amaze to the international skilled world. And this year we will do it more than ever”, it stands out Michael Hehl, partner manager and spokesman of the management of Arburg. “To offer an advance of the innovative program of the fair, will present previously a selection of world-wide novelties and other appearances stood out so much in the skilled presses as in our website”, indicates Hehl. “But also there are revolutionary innovations that is not possible resumir in words, but simply it has to see them one same.“These are the aims that pursues the campaign of communication for the fair K: 'The freedom it is necessary to live it!'. From here that it was indispensable to visit the stand of Arburg in the K 2013 to witness with us the start of a new era”.

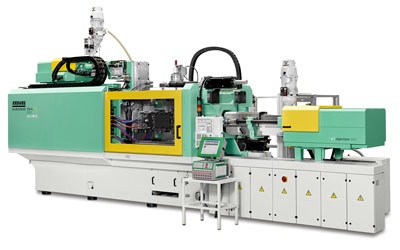

In the section of machines of injection, the fair of Düsseldorf will serve to present to world-wide level the Allrounder 820 To electrical, which complete the electrical series of technology tip Alldrive. This machine incorporates a unit of closing with kneepad with a strength of closing of 4.000 kN and a unit of electrical injection of size 2.100, both components again development. The empty existent up to now in the rank between 3.200 kN and 5.000 kN remains in this way covered. The same is applicable to the hybrid series of high performance Hidrive, which will be also available in the future with this new size of kneepad. With the new sizes of unit of electrical injection and of unit of closing the program of Arburg wins in modularidad, what will allow to the customers can configure his Allrounder of form even more detailed to the application and to the product, and follow increasing the efficiency in his production.

For the sector of the automation, the company germana, together with his partner collaborator fpt Robotik, will present a world-wide novelty: a robot of six axles Agilus of the company Kuka with surface of handle 'Selogica' implemented. This robot is suspended in a willing linear axis transversalmente to the machine. The combination of the robot of six axles with a linear axis makes possible movements more dynamic and interventions faster in the mould. The result are time of cycle shorter and a greater productivity. Another advantage of this mobile solution is the greater zone of work, since the small robot can displace on the axis and the surface of the floor underneath, offering an use without limitations. Of this way, the robot Agilus can realizar numerous tasks in the production of pieces injected. Regarding size and performance, the robot has been configured for capacities of load between 6 and 10 kg, with what is perfectly adapted for the needs of the transformation of the plastic. At the same time it supposes an economic solution for the realisation of tasks of manipulation.

The exhibition will have a new solution of automation based in an Allrounder 470 S for two components, that will allow to see the last development of the sobremoldeo by injection of compound of particles foamed (PCIM). This process, still young, has been developed jointly by the companies Ruch Novaplast, Krallmann and Arburg, and opens possibilities totally new for the light construction. In the exposed machine in the K injects in a first step the llanta of plastic in the tyre of foam of particles entered. After the transfer of the prepieza in the mould realizar the sobreinyección of the tyre with a TPE. The robot of six axles realizar all the operations of manipulation, from the introduction of the tyre foamed until the delivery of the pieces finished to the installation of packaging. Here, the stock exchanges print during the process.

Another innovative process for the light construction is the moldeo by direct injection of long fibres. In this process, a lateral feeding in the unit of injection incorporates fibres until 50 mm of length directly in the mass melted liquid and distributes them homogéneamente. It is possible to adjust individually the length of the fibres, the percentage of the same and the combination of materials. The new process offers a big flexibility and the possibility to develop a 'know-how' own. To this adds an advantage of significant costs, since the materials of game (plastic and rovings of fibre of glass) are cheaper that the granulated of long fibre. The process will show in an Allrounder 820 S hydraulics of energetic consumption optimised endowed of servohidráulica working with a mould of the company Georg Kaufmann Formenbau AG. By means of the sobreinyección of insertos thermoplastic reinforced with continuous fibre (organic sheets) obtain stable compound components and of high resistance with inferior weights to 300 grams for upper lengths to 500 mm. The organic sheets combine effectively two or more material, with what improve his respective properties. The continuous fibres, generally of glass, carbon and aramida in shape of fabric or rejilla, determine the mechanical properties, such as the resistance and the rigidity. Inside the compound, the material of the matrix is the manager of the transmission of strengths between the fibres and protects the structure of reinforcement of the pandeo and the environingingmental influences.

The Allrounder 720 To electrical for two components, had horizontally on the dish of mobile closing of the machine.

Another novelty presented is the application with cubic mould totally electrical for the manufacture of enclosures realizar in collaboration with the partner Foboha. The Allrounder 720 To electrical for two components possesses a strength of closing of 3.200 kN. The unit of injection 800, of greater size, is had horizontally, whereas the unit of injection 400 smaller is mounted horizontally on the dish of mobile closing, displacing with this last. 'Totally electrical' means in this application that so much the twist of the cube like the linear trip of the mould of 12+12 cavities realizar by means of accionamientos electrical. Like result obtain advantages in precision and time of cycle, and with this a greater productivity of the installation.

In addition to the technology of electrical cubic mould and of the sobremoldeo by injection of compound of particles foamed will present also another application multicomponente. In collaboration with the company Rico will show the union between a thermoplastic and a liquid silicone (LSR). An Allrounder 570 S hydraulics with two units of willing injection in L will produce a sucker like the used in the sector of the logistics to move heavy or bulky loads. For the manufacture of the sucker, a system of robot Multilift V enters a casquillo threaded of metal, which sobreinyecta with the two components.

With more than ten exposed machines in the stand ferial own and more than ten machines in stands of other companies, Arburg will occupy a place stood out in the K 2013 and will be able to show all his range of products: machines Allrounder electrical, hybrid and hydraulics, horizontal and vertical machines, solutions of automation and transformation of thermoplastic, thermostable and silicone, transformation multicomponente, sobreinyección of insertos, technician of containers and packagings, medical engineering and much more. All the models presented are configured exactly to the respective requirements of the product and requirements of production, and show the future of the efficient production of pieces of plastic with the technician of Arburg.