Kreyenborg presented at the K CrystallCut system, for a cost reduction in the production of PET

As the price of the PET continues to fall, the pressure of the production costs for the polymerization of PET and recycled PET continues to grow. The system of pelletizing CrystallCut of BKG Bruckmann and Kreyenborg GmbH, represented in our country by Commercial Coscollolaoffers an effective way to reduce these costs. To an average energy cost of 12 cents/kWh, saving that can be achieved can be up to 15 eur/t. In this way, and polymerization of PET plants that today have a production capacity of 600 tonnes/day on day, daily savings can reach the 9,000 euros. This translates to an annual savings of more than three million euro, in addition to representing a savings of 26 GWh. These same figures are repeated in the recycled PET lines, so the return on investment are produced very quickly. In addition, due to the crystallization of the granules from the inside to the outside, gets a better crystal structure which in turn saves energy costs at the time of return to melt the material.

Kreyenborg also increases the production capacity at plants of extrusion film blowing due to continued use of the mechanisms of change of filter. Kreyenborg has equipped several production plants film blown for Hosokawa Alpine, with continuous filters of the type K-SWE changers.

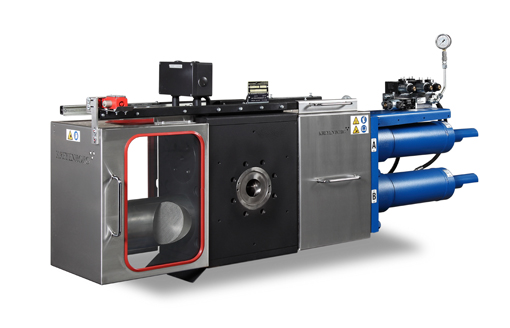

To ensure a smooth and reliable filter during operation change, provided to filter exchangers completely independent control. Adaptation must eliminate lines of production stops during the filter change and improve the result of the filtration, i.e. the objective is an increase the availability and productivity of the plant. The changer Kreyenborg K-SWE is a modern filtration system, of higher quality, which allows the exchange of the mesh without interrupting production. This means that the system can continue operating while the dirty filter elements are replaced or the finenesses of filtering of different production batches are changed.

Continuous filters of the type K-SWE changers.