Hall 5, stand C21/D21

BASF presents numerous innovations in all segments of the plastics

Summarize what a multinational BASF presents at a fair as K, the most important in the world and in which BASF plays at home, is little less than impossible. We offer here, however, an attempt to summarize the most significant of their innovations, information that we will be complemented by more detailed information in the coming months. As a statement of intent BASF wants to be closer to customers with your business's specialties and presents products and concepts for the automobile, plastics and foams for domestic industry, plastic for storage of data, as well as developments in the field of the additives and surface finish and polyurethanes.

At a Conference of the international press in Ludwigshafen in which universal plastics / Interempresas was present, Dr. Martin Brudermüller, Vice President of the Board of Executive Directors of BASF SE, gave an overview of the plastics company business strategies. BASF, he said, will continue to grow above the market with its plastics, their monomers and their polymers commodities. Gathering all its new Performance Materials division special polymers has strengthened its approach to the customer and its business of special polymers with enlargements of capacity, new plants and acquisitions, as well as investing in commodities such as MDI and TDI. Its entry into new sectors, such as the wind energy, allows you to benefit from their knowledge and ready to offer existing products in the form of materials based on renewable materials.

The Performance Materials division created in January 2013, explained the head of the same, Raimar Jahn, aims provide solutions and services, growing up profitable, participate in growth markets and new business development. In the first quarter of 2013, the sales of the division amounted to 1.6 billion.

Product and new concepts for the automobile

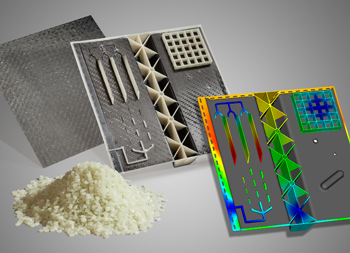

BASF enters the market of semi-finished parts of composite for the automotive industry. On the occasion of the 2013 K Basf announces its intention to expand its activities in the field of engineering plastics for the manufacture of cars with a completely new approach. Ultracom is a package of three components: semi-finished products reinforced with continuous fibres, compounds adapted to them and the corresponding support of the engineering. The main innovations are laminates based on fully impregnated woven fibres Ultramid or Ultradur, polyamide and BASF PBT. The second component of the package Ultracom consists of materials to shape individually developed for use with these laminates. The third component refers to the broad support of the engineering of BASF. All BASF wants to have a role protagonist in the future development of light car with plastic.

BASF will be starring in the future development of light car with plastic.

As part of the package Ultracom BASF has created a pilot plant of high capacity for composites in Ludwigshafen. From March 2013 the equipment is being used to produce multifunctional composites for testing to a process of foaming mold and overmolding. The central element of the cell is a six axis robot with a special hand. The company has developed its own multi-functional piece for testing. Call piece CIFO (Combination of in-mold forming and overmolding initials) makes it possible to research parts of composites reinforced with continuous fibres. Simulation Ultrasim instrument is one of the parts of the package Ultracom. It allows to observe the behavior of components made of thermoplastic laminates and from overmolded polyamide.

Degrees for blowing and extrusion

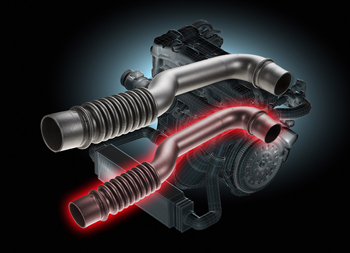

Injection material Ultramid Endure a very high temperature resistant polyamide-based is now available also in the version for molding blow. The new grade is called Ultramid Endure BM and has the same technology of stabilization to the grade for injection. It also presents the same resistance to the 220 ° C in continuous use and up to 240 ° C peak temperature. This degree covers a gap in the market.

Ultramid Endure BM blow has the same technology of stabilization to the grade for injection.

One of the extensions of the range covers polyamides 610 of BASF. The K presents two degree flexible Ultramid balance for pipe extrusion, designed especially for the automobile, the machines and lines of oil and gas sector.

Domestic

In this environment BASF puts the focus on the complete family of polyamide Ultramid Yes (improved surface - enhanced surface) for the furniture industry. It presents four new versions of its range of polyamides to this industry, presenting high surface quality, excellent mechanical properties and chemical, even with flame retardants. One of the first products manufactured in series with the new Ultramid SI series is the Office Chair MOVYis3 that BASF has developed the Interstuhl manufacturer.

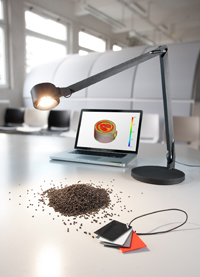

Among the recent projects of designfabrik can highlight new minimalist lamp Winkel w127 Wästberg manufacturer, which has been developed by the designer Dirk Winkel in cooperation with BASF designfabrik. Manufacturing has resorted to special polyamide Ultramid S Balance, allowing the economic injection molding and an elegant appearance.

Minimalist lamp made with special polyamide Ultramid S Balance.

Investment in high performance plants

Very sophisticated additives to plastics become sustainable high-performance materials. the company also offers CSBS - Customer Specific Blends (specific blends for customers)-, mixtures of additives made tailored to the individual needs of clients. The most recent investments have been made in Bahrain. With a capacity of 16,000 tons, the new plant is one of the largest in the world of this type. Also the antioxidants of Singapore plant is adapting to meet the needs of asia and the Middle East. In general terms, BASF will invest several hundred million euros in the expansion of its production plants and r & d for additives centres in the next five years.

Especially attractive is product Infinergy, the first thermoplastic polyurethane foam (E-TPU) in the world, said experts. It shows an excellent resilience and a particularly high duration in a wide temperature range. The first product made with this innovative material is the sport shoe to run Energy Boost of Adidas, the German sporting goods manufacturer has developed together with BASF. The midsole of the new E-TPU combines cushioning and high elasticity to improve the properties of this footwear. It remains stable even at low temperatures of - 20 ° C.

The first product made with thermoplastic polyurethane foam is the sports shoe for Energy Boost from Adidas.

Following in the domestic sphere, the compostable plastic ecovio of BASF has found its first application in production conditions in a packaging solution. Capsules for coffee beanarella Swiss company has resorted to the new level of injection IS1335 ecovio for capsules since they not only play their role, but they may be disposed of with organic waste for compost.

Plastics for data transmission and water environment

BASF has developed a new degree of Ultradur especially for slim optical cable casing. With Ultradur B6550 LNX, the company increased its existing range of PBT for extrusion of protections of cables. Due to its fine crystal morphology presented a crystallization faster than all previous materials and has a very high viscosity, especially with low ratios of shear.

On the other hand, it proposes an economic replacement of metal with new partly aromatic polyamides. These materials recently presented by BASF can replace metals in applications in which until now it was difficult to find plastics. It's Ultramid D3EG10 FC Aqua and Ultramid D3EG12 HMG. Thanks to its resistance to chemicals and hydrolysis, the Aqua degree is ideal for components in contact with food as in the case of flowmeters or drinking water. The excellent properties of Ultramid D3EG12 HMG explained the reason for the HMG (High Modulus Grade) suffix. Its excellent surface quality opens up new opportunities in Office chairs or valves.

PBT resistant to hydrolysis to electrical items can be noted also in the car. It is able to pass climate tests find standard class 5. Ultradur HR integrates delay flame and transparency laser, so it is ideal for applications in electric vehicles. Examples are control housings or connectors for charging, or parts that must be welded by laser from different materials.

On the other hand, for the industry of the ' shipping "has been developed a special block of foam blanket to prevent spills. BASF and the South Korean company Samsung Heavy Industries have developed a new concept to avoid spills from gas during their transport in tanks. It's a kind of blanket or rug based on cubes with a volume of one cubic meter, made from Basotect foam. In 2012 this system obtained the certification of two leading companies in the sector of the transport by boat.

The art of the additives and surface finish

Additives for mechanical recycling of plastics are one of the important topics at BASF. Its additives make more than just facilitate recycling, also help the recycled materials have better sometimes even than virgin materials properties. The materials recycled with subsequent treatments are typically less stable, a problem that can be solved with new stabilizers as to the functional additive Joncryl ADR in the recycling of PET or with lines Recyclostab, Recycloblend and Recyclossorb.

BASF also offers the complete analytical support for 160 pigments, which facilitates the safe use of products in sensitive applications, such as in the medical sector, that of food, toys, pipes for water or hygiene products. Now, BASF has optimized its range of products to support 160 pigments that can be used in sensitive and non-sensitive applications. With this approach to a wide range of applications, BASF reduces contamination risks in the industry and throughout the value chain.

In the section of surface finishes, Steron coating is now available in standard and all over the world. A few years ago BASF created new ways to provide the surfaces of appearances and completely unusual textures using the dispersion of polyurethane under the name Steron. Now the company has automated technology and launches the first applications in the mold industry. The coating system combines the characteristics of the leather, artificial leather, fibers and soft text materials. The possible fields of enlargement are automotive, bags, accessories, shoes, furniture, or containers of high quality. The material is air-permeable, scratch-resistant and repels dirt. The first production plant is already being built.

Polyurethanes in all forms: Compact, foam and coated

Elastocoat material continues to conquer new fields of application. Based on polyurea, is sprayed on surfaces that are to be protected, providing a coating that reacts to form a membrane. In the construction used, for example, to cover floors of parking surfaces. A striking example are the rooftops of the largest mosque in central Asia in Astana, capital of Kazakhstan.

The Elastocoat material is sprayed onto the surfaces that are to be protected.

It also offers a new antistatic additive for plastics industry. The load electro static of plastics may cause damage to the industry. BASF has developed an anti-static thermoplastic (TPU) polyurethane which is marketed under the brand name Elastostat. It stands out for its permanent anti-static effect, their mechanical properties and their compatibility with non-polar polymers. The new masterbatch for TPU opens new possibilities of applications, especially in the sector of packaging such as big bags, drums of plastic or cans. You can also apply in the automotive and transport systems for the electronics industry.

Note that BASF moves comfortably in the environment of the Polyurethanes. Thus, it presents the first high performance insulating material installable panel-shaped. BASF researchers have developed an insulation material only that will bring to market in just a few years. It is a new type of aerogel to be offered as a panel of great mechanical resistance. With a value of less than 16 mili lambda Watts per meter and Kelvin (mW/m•K), presents an exceptional insulating ability, is very thin and light and will occur in the form of panel ready to be installed and easy to process. The main areas of application are in the construction and refrigeration sector.