Engel Injects the future

Give value to the customers. This is the approach of Engel, represented in Spain by

Engel Has 8 plants and 29 subsidiaries. The fiscal year 2012/2013 reached some sales of 950 million euros, a very positive result in front of the 834 of the previous exercise. 65% of the turnover came from of Europe, 18% of Asia and 17% of America. “We think that Asia will reach 20% in the next years and is a geographic zone in which we have to grow more” said Neumann.

Of the previous K to this, have invested 67 million euros, mainly in the enlargement of the productive capacity in Europe already Asia, but also in the improvement of the productive means, with new lines of assembling and a greater automation.

All this redunda in figures very positive. As it said Neumann his quota of market in Europe was of 30% in 2012, in front of 23% of 2004. In Asia has 10% (2% in 2004), in America with 18% (9% in 2004) and in the world 14%. In this sense affirmed: “I Think that in Europe will not increase more the quota of market, because we already are very entered”. And it did an interesting comment basing in data: the value of the machines increases more than the number of machines, by the tendency to use machines bigger and more prepared technologically speaking. In fact, observing the Chinese market, sees that the machines of low technology and of low specifications are registering a lower demand.

In the K 2013 Engel presents 25 machines, 12 of which in his stand, all they headed to show new applications and new records of efficiency, as well as to give answers to the big challenges of the future. The cells of exposed production combine a high level of integration of processes and automation, high performance, sustainability and reliability of the process. Can stand out like novelties the two new inyectoras and-speed and and-motion 30 TL, the first pedal of brake done in composite realizar in an alone phase and the greater vertical machine never presented by Engel in a fair.

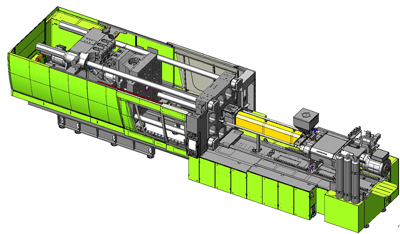

E-speed 650 Engel

The Engel e-speed 650 has been designed as a high-performance machine destined to the sector packaging. The development of this new machine series e-speed took into account two aspects: the introduction of higher closing forces and the new drive concept that ensures the best energy efficiency even at high speeds. It is a hybrid 650 ton machine with power and hydraulic injection unit. It can reach 2 dry cycles, 5\1s\2y has a new kinetic energy storage system. Its encapsulated brace system incorporates bearings with the patented system of stamping Engel that keeps the oil in the bearing and generates less friction, i.e., results in a lower energy consumption.

Closed-circuit lubrication system reduces the consumption of oil by 90%. Annual savings of 1,620 euros with the new brace system can be achieved.

If we stop at the injection unit, inline unit stands out for the high dynamics of injection and plasticizing electric drive, allowing speeds of injection of up to 800 mm per second. Diameters 80-90 spindles are available with this machine e-speed 650.

e-motion 30 TL

Another novelty is the extension of the series of electrical machines e-motion, adding 30 tonne model e-motion 30 TL without columns, a high precision machine, with great parallel between dishes and very good distribution of the closing force. It is a machine that benefits from the advantages of a machine without columns and an electric, with energy-efficient. It is ideal for parts optical and electronic components.

Perhaps the most striking innovation of this machine is its intelligent frame which replaces the concept of double-bed. The result is a most parallelism between dishes and a better distribution of the force by the dish exeptionally mould carriers.

In regard to the injection, the e-motion 30 TL is equipped with the recognized unit 50 inline, which provides a speed of 800 mm/s. They are three camera in standard diameters: D15, D18 and D20.

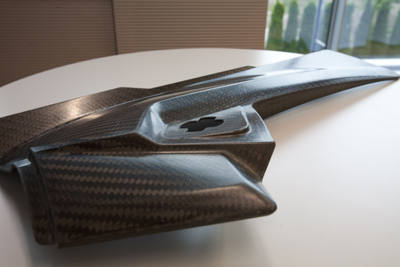

Composite brake pedal

Together with ZF Friedrichshafen Engel has developed an application that represents a milestone in lightweight car construction. It's a plastic brake pedal geometry optimized and resistant strains. On a vertical machine Engel insert 1050 H/200 with robot easix and oven infrared, the process begins with the heating of thermoplastic semi-finished products reinforced with fiberglass (organic sheets) which are then preconforman in a mould and immediately is sobremoldean polyamide. The component is ready for installation, does not require any cutting or further treatment.

To design it has adapted the structure of layers to the burden of the piece, in such a way that it has been able to reduce weight 30% compared to conventional steel pedal. In addition, have been removed in the process much increasing productivity and reducing costs per piece. Easix multi-axis robot control is fully integrated in the fuel transfer.

The largest vertical

The model v-duo, already presented last year, it will debut at the fair with a light piece application. It is the largest vertical injection ever presented at a fair by Engel, but it features a compact design which reduces your height and your weight.

A 700 v-duo will produce parts for the KTM X-Bow sports car through a process of RTM, while a linear robot viper 20 manipulates parts.

In this segment the machines are also very efficient. The model is new e-duo that consumes only 20% of a conventional hydraulic injector hydraulic oil. It presents a high precision, high repeatability, greater energy efficiency and 14 different combinations.

In the area of the car is also the combination of three processes in a duo 3550/650 peak M combi for soft parts. Single-stage, shared with Georg Kaufmann Formenbau, Varysoft process is used to manufacture dashboards for the Hyundai Kia Automotive Group model.

Other products on display

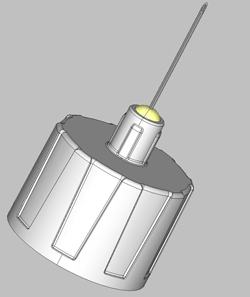

Visitors can also see something new for the medical sector. Devices for the transfusion of blood with an integrated filter with three components, which are injected in an e-victory 310 H/80W/50V 160 combi (electric injection unit and a system for hydraulic movements ecodrive) under Cleanroom conditions.

Following in the medical field, it presents a manufacturing cell very automated for safety holder devices of insulin, with a cast of 96 cavities whose nuclei have a diameter of 0.3 mm.

In the field of optical parts, the challenge is to manufacture parts of very thick walls and a cycle and precisely appropriate for the requirements of each sector in an economically viable process. Increasingly more optical components for headlights of cars and lighting in buildings from plastics are used. On the one hand, the glass replaced by plastic to reduce weight and costs and, on the other hand, plastic opens possibilities in design. The challenge is to achieve a balance between the highest optical quality and competitive costs. Engel demonstrates how to achieve this using the overmolding in e-motion 200/110 T with integrated 12 viper robot. First manufactured a piece preformed in a mold of Krallmann, then the piece is covered with layers of the same material. In this process of triple-layer is a cooling of the middle layer out of the mold. The process requires only one injection unit. Engel has resorted to this technology multilayer optics of high quality in a process that greatly reduces the cooling time.

Another point of attention will be the liquid silicone. The main demands in this field are: it should be an automatic process, not generating waste, without burrs and that doesn't require post treatments. All this will prove it a fuel transfer e-200 H/80W/120 combi with robot viper 20 victory.