New and improved radial milling of hard ceramic EADE

Perhaps the most basic assumption in the machining is that to cut materials of high resistance, more resistant tools are required. Proprietary nickel-based alloys used in gas and steam turbines are, for example, one of the most resistant materials in the world and are constantly developing to allow power plants to operate at much higher temperatures. This not only offers more power to those who need it, but that increases the performance of the plant and reduces or eliminates harmful emissions. The superalloys like Inconel, Waspaloy and René, among others, come into play when it comes to turbine vanes and other parts that require high strength, excellent resistance to creep at high temperatures, stability phase and resistance to oxidation and corrosion.

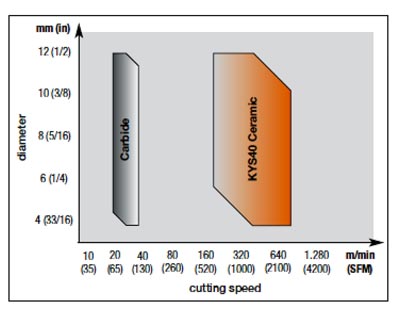

But machining these materials can be slow, laborious and expensive. In general, integral carbide tools normally operated at a speed of between 65 and 200 SFM (20 to 60 m/min) in materials with a limited shelf life. However, new radial strawberries hard ceramic and KYS40TM quality of Kennametal, company represented by Kenci, presented by orders of magnitude improvements in machining of high strength nickel based alloys, trim at a speed of up to 3,300 SFM (1000 m/min) cutting and still life enter two or three times greater than in the case of comparable comprehensive hard metal tools.

The first in the industry

Cutting tools made in ceramic, mainly in oxide aluminium (Al2 O3), lead to exist since the beginning of the 20th century. In 1913 the patents for the cutting tools of ceramics that were sold in the U.S. were issued in Germany. In the 1950s. Today are still using indexable ceramic plates because they can operate at a higher speed in certain applications, but the radial hard ceramic burrs are rarely, as being more fragile than hard metal performance is not good. In fact, many turbine manufacturers have opted to produce its own radial carbide cutters integral so much consuming this type of tool.

New quality of ceramic SiAION KYS40 of Kennametal and the overall design of radial hard ceramic Strawberry now assume more effectively for high temperature based on nickel alloys rough. "In Super alloys based on nickel, cutting speed can be up to 20 times higher in comparison with strawberries radial integral hard metal, and also because of the excellent ceramics thermal resistance and the more resistant cutting edges (negative angle), the life of the tool can reach multiplied by five and even more", indicates Thilo Mueller, product manager global at Kennametal.

There are available two types of radial milling of hard ceramic KYS40: the six channels for the facing and profiling, and the four channels with neck for grooving and in cavities work. Both product lines are also suitable for ramps, helical interpolations and trochoidal machining strategies.

Wear mechanisms and indication of wear on radial drills of hard ceramic, completely different to the carbide cutters, allow to work with radial ceramic cutters in applications in which it would be necessary to replace hard metal tools. This is one of the reasons why new radial quality KYS40 Strawberry is disposable and its use goes beyond ordinary wear and tear.

Machining of turbine blades

Well driven by fossil fuels, water or nuclear energy, almost all power stations of the planet use turbines to generate power. Produce, manage and maintain these fundamental components is vital for keeping the energy flow.

This puts too much pressure on manufacturers who must constantly update their machining strategies. There are many factors that influence: what does it take? Many similar palettes, or few palettes but different design? Machining centers and multiple configurations, or machines do lack multitasking and multi-axis? What CAD/CAM system is being used and what is the experience of the workers?

And, of course, what are the best options of tooling for machining operations? The results of the tests carried out recently with new radial Strawberry hard ceramic KYS40 are insightful.

Firstly, ceramics of KYS40 improved quality in four- and six-channel version incorporates a larger nucleus which improves the rigidity of tool and reduces flexion at higher cutting speeds. Ends with optimized geometry and the helical angle of 40 degrees increase cutting action and chip evacuation.

The chipping of the profile of a palette of turbine made of Inconel 718 by machining dry, radial four-channel EADE Strawberry worked to 645 m/min (2116 SFM) with an advance of 0.03 mm/z (0,0012 IPT). The depth of cut (ap) was 0.5 mm (0,0197 inches) and width of cut (ae) of 11.4 mm (0,866 inches). Compared to conventional solutions, four-channel Strawberry lasted three times more rough in less time. This application tripled the pieces produced by strawberry.

Hard ceramic EADE radial Strawberry was proven profiling a blisk (disk with integrated pallet), manufactured in Inconel 718, and using compressed air for the evacuation of chips. Unlike the conventional tools of hard metal, in the rough to give the component its final geometry, more like powder than traditional curly shavings shavings, are created so that only required compressed air to remove from the cutting area. The test conditions are as follows: 679 m/min cutting speed (2228 SFM), advance of 0.03 mm/z (0,0012 IPT) and depth of cut varied up to 0.5 mm (0,0197 inches).

Got two segments of blisk machining, using a single tool still needed 12 minutes per segment, staff described as 'unprecedented' "."

New hard ceramic radial strawberries Eade are also included in the new 'Kennametal Innovations' iPad app that can be downloaded for free at the iTunes App Store. It is very easy to navigate through the application and perform searches by entering key words to find specific solutions for certain product groups and tools. Main features:

- Product animations that provide a clear visual representation of processes, with direct links for detailed information.

- A map of navigation with drop-down menus offering additional information, including tables and graphics that can be customized and extended.

- User-oriented navigation that, thanks to the possibility of selecting data, allows you to quickly perform comparisons necessary to get competitive and quality products.

- Demos and videos to get a real and valuable experience and learn about the technologies that are currently being used for tools.

Kennametal offers its new radial strawberries of ceramic KYS40 in ranges of between ½ and 3/16 inch (4-12 mm). To work with the tool any special mounting is not required, it is enough with a mandrel, high performance mechanical or hydraulic plate, although the dish must be able to operate at high speeds required for the machining of superalloys. To ensure maximum life of tool recommends a balanced precision.