Technicians advanced of characterisation of material to optimise the design of machine of aplanado of sheet via numerical simulation

And. Silvestre(to), J. Mendiguren(to), And. Sáenz Of Argandoña(to)to, L. Galdosa, D. Garcia(b), M. Leizaola(b) And To. But(b)

(to) University of Mondragon, Loramendi 4, 20500, Mondragón, Spain

(b) Fagor Arrasate, Neighbourhood of Saint Andrés 20, 20500, Mondragón, Spain

13/06/2013In this article present the results obtained of essays of traction compressesion for a steel of high resistance and observes like the models of endurecimiento cinematic are valid and necessary for the modelling of this process.

1. Introduction

The competitiveness and specifications required by the consumers in the market during the last years, have promoted to the development of new materials and processes of manufacture that contribute improvements regarding environingingmental sustainability, hygiene and price. In this context, has loaned special attention to the steels of high resistance (HSS and AHSS), by his reduced weight and high resistance.

The interest by these materials has been mainly notable in the car industry, where the environingingmental and economic restrictions imposed in the last years have promoted the development of light trucks, which is tied directly with the reduction of the consumption of fuels and the reduction of the generation of CO2 [1-3]. However, still today it exists some uncertainty regarding the behaviour of these materials and how have to adapt to the processes of manufacture. The use of the steels of high resistance supposes a new challenge for the manufacturers since they show a conformabilidad limited, a strong influence of the springback and require big strengths to process them because of his high resistance [4,5].

During the process of manufacture of sheet, these are subjected to laminación in cold and in hot, what contributes some mechanical properties to the material. However, during this process, the sheet adopts defects of form and in his interior generate high levels of residual tensions that do that the quality of the sheet was not the suitable. These effects see increased in the course of the bobinado, where the sheet tends to adopt the form of the coil. By all this, the tolerances of planitud and specifications of the material sued by the market can not be reached by means of the process of laminado only. A correction of these defects of sheet and the release of residual tensions in the interior of the material is necessary.

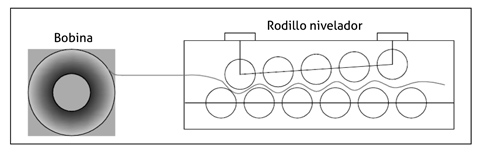

Exist distinct technologies of aplanado to delete the defects of sheet and reduce residual tensions, however the aplanado by rollers is the most usual. In this process, the sheet is bent in alternative steerings by a true number of rollers with a gap variable between the upper and inferior row as it shows in the Figure 1. The material is subject to deformations elastoplásticas with the aim to delete the residual tensions and homogenise those that can not be deleted. There are a lot of processes that can see affected if the sheets have not been aplanadas properly because of the existence of the internal tensions and defects of form, as for example processes of pressesing and tooling, processes of cut, fimbriated, etc. [6-7].

The theory of plasticidad establishes that in processes in which a material is subjected to loads cíclicas of traction-compressesion, once that said material reaches his initial elastic limit, the curve of traction-compressesion changes in the successive cycles. It is what designates cycles of histéresis. The cycles of histéresis are specific for each material and go changing in each cycle, by what the elastic limit also. Given this situation, in which the sheet modifies his behaviour in each roller for being varying his curve of histéresis, results interesting to deepen in the study of the behaviour of material when it sees subjected to this type of loads [9].

In concrete, in this work goes to study the behaviour of a steel of high resistance, the TRIP700. For this, the mixed model isotrópico-cinematic of material developed by Chaboche and Lemaitre (1990) [10-12] has been selected to predict the behaviour of this material, by his capacity to predict the majority of the characteristic phenomena of the processes of plasticidad cíclica, like the effect Bauschinger, and for being implemented in the majority of the codes of finite elements. In the first place, it presents a brief explanation on the defects of typical sheet and the phenomenon of aplanado by rollers. To continuation, describes the model of material selected to define the behaviour of the material. Afterwards, it shows the characterisation of the materials, that has carried out by means of essays cíclicos of traction-compressesion, and the back adjust of the model to the experimental data obtained in the essays. In the following section presents the model of finite elements developed to simulate the process of aplanado by rollers. In the last section of results, compare the different simulations realizar with the mixed model of material obtained in the previous section and a model isotrópico pure.

2. Aplanado By rollers

2.1. Defects of sheet

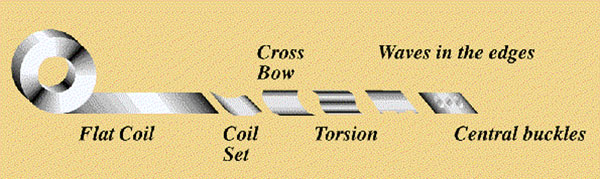

The defects of sheet occur because of the existence of residual tensions inside the material. These tensions appear by different reasons as for example, a cooling no homogéneo in the process of laminado, pressesure no uniform in the rollers of the laminado, process of bobinado, impurities in the material, etc. During the process of laminado, the tensions applied with the rollers of work induce heterogeneous plastic tensions in the width and thickness of the sheet. This generates distinct types of defects that show in the Figure 2. The lateral stock exchanges and central waves are caused by longitudinal tensions along the sheet. A difference of length between the longitudinal fibres of the extremes and of the central part causes this type of defects. The transversal residual tensions generate a difference in the length of fibres along the thickness. This causes that one of the faces of the band find in a state of traction and the another of compressesion.

Because of the no homogeneity of the profile of tensions along the thickness, the sheet tends to curvase after the cut because of the moment developed by this distribution that is not symmetrical with regard to the neutral fibre [13-15].

Appears 2: typical Defects of sheet.

Does not exist a minimum deformation imposed to which the sheet has to subject during the aplanado so that the defects are deleted. However, in bibliography can find some recommendations according to the type of defect [13]. To delete the defects caused by the form of the coil will be sufficient with reaching 2 times the deformation of the elastic limit. This operation could realise with a simple enderezadora. To delete the others defects caused by the differences between internal tensions in the interior of the material like stock exchanges, waves, crease, etc., the sheet has to be deformed until 4 or 5 times the deformation of the elastic limit. It needs a machine of aplanar robust to reach these levels of deformation, thus the machine aplanadora by rollers is used for this end.

2.2. What is aplanar by rollers

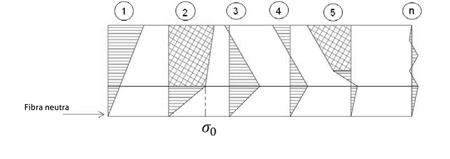

A machine aplanadora of rollers is formed by two lines of rollers. The upper line is designed with an inclination that causes that the deformation induced by the first rollers was high and that this go decreciendo to measure that advances to the last rollers. This configuration of the rollers provides better results in the quality of aplanado final that the obtained with a configuration of parallel rollers [16]. The sheet happens through the rollers and bends alternatively causing that the fibres of the surface are subjected to efforts of traction and compressesion. The process of aplanado consists in an elongación plastic of sheet with the aim to unify the lengths of all the longitudinal and transversal fibres, so that the internal tensions are minimised and homogéneas (Figure 3) [17].

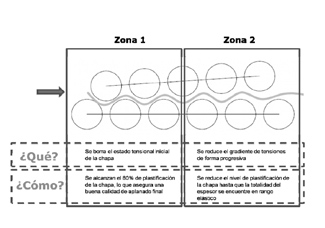

Exists a controversy about which have to be the parameters that define the optimum conditions for which considers that a sheet presents a good quality of aplanado. Traditionally in the industry establishes like criterion to obtain a good quality of aplanado, that at least between a 70-80 % of the thickness of the sheet there is plastificado [18,19]. Usually this maximum of plastification reaches between the 3º and 4º roller and afterwards goes reducing until in the exit the sheet finds totally in elastic rank. However, there are authors that analyse the level of residual tensions to the exit or the curvature of the sheet like parameters more indicativos of the quality of aplanado [14].

2.3. How aplana

To analyse the process of aplanado, is necessary to understand that it occurs in the interior of the aplanadora. Why a sheet goes in in the rollers with defects and goes out without them? The process of aplanado can divide in two parts, the first corresponds with what sucede in the first rollers of the aplanadora, and the second part corresponds with what occurs in the rest of rollers. In the first part, the penetration that exert the rollers, and therefore the deformation that suffers the sheet is greater. In this section the sheet develops zones of plastic deformation that goes increasing to measure that bends between the rollers, until arriving to a maximum of thickness plastificado, that is used to to reach in the 3º and 5º roller. The purpose of this first section of big deformations is that the greater part of the fibres of the thickness reach the elastic limit and therefore they remain plastificadas, whereas the central zone, near to the neutral fibre, remain in elastic region.

Of this form, achieves suppresses the gradient of tension in the width of the sheet, generating a new profile of tensions in the thickness. After the first part, the penetration exerted on the sheet goes diminishing until in the exit, the rollers hardly deform it [20]. The purpose of the second part is the one to delete gradually the curvature of the sheet and reduce the gradient of tensions generated in the first section along the thickness, to obtain to the exit a sheet in which all the thickness was not plastificado (Figure 4) and with a reduced and homogéneo profile of residual tensions.

If it selects a fibre of the sheet and analyses his behaviour in all the process, is will see subjected to cycles of traction compressesion, so many like couples of rollers there is in the machine. According to the theory of plasticidad, because of the changes microestructurales during the processes of loads cíclicas, the physical properties and the answer of tension in the material go modifying. In particular, the steels suffer an endurecimiento cíclico or increase of the resistance to the deformation when they are subjected to loads cíclicas. The intensity with which the material toughens in each cycle reduces to measure that increases the number of cycles until reaching a value of saturation [11].

2.4. Variables of influence

there is different factors involved in the process of aplanado, and of them depends the final result of the aplanado of the sheet. Thus it is important to develop a tool of calculation, as it is a model of finite elements, that allows to analyse how these variables influence in the quality of aplanado and like this can optimise the design of machine without need to realise a big number of experimental essays. The main factors involved in the process are the diameter of the rollers, the distance between rollers, the number of rollers, the type of material, the thickness of the sheet and the initial curvature that has the sheet [7,13,19-21].

An optimum performance of the machine aplanadora that design taking into account all these factors, has to ensure [18]:

- Reach a percentage of plastification in the sufficient thickness to delete the defects (generally estimated in 80%)

- The residual tensions to the exit have to be minimum

- does not have to exceed the maximum strength neither admissible moment by the machine

3. Model of material

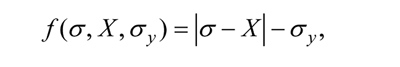

During the process of aplanado, the material sees subjected to deformations elastoplásticas cíclicas, thus, is necessary the development of constitutive equations that describe the behaviour of material under plastic deformations cíclicas. The correct description of the plastic behaviour of a material comes given by the definition of a criterion of fluencia, a rule of flow associated and a law of endurecimiento. In the first place, the criterion of fluencia will indicate the point in which it begins the plastic region. The criterion of fluencia of von Mises is widely used for plasticidad cíclica and is implemented in the majority of the codes of finite elements. The criterion for the case uniaxial defines eat:

The elastic part of the deformation describes by means of the law of Hooke. To his time, the deformation plática follows a rule of fluencia that expresseses the relation between the components of tension and deformation of the following form:

Where λ it is the multiplicador plastic no negative that it has to satisfy the condition of consistency λ•f=0 (4).

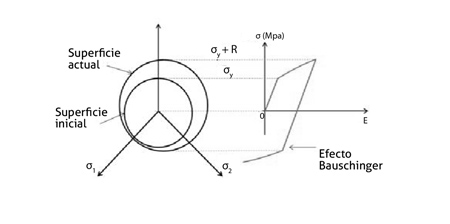

When the metallic sheet is subjected to cycles of traction compressesion during his step through the rollers, according to the theory of plasticidad, the sheet will suffer changes microestructurales that do that the physical properties and the answer of tension in the material go modifying. In particular, the steels can suffer an endurecimiento or ablandamiento cíclico when they are subjected to loads cíclicas. The intensity with which the material toughens or softens in each cycle reduces to measure that increases the number of cycles until reaching a value of saturation. Thus, it is necessary to define the behaviour of endurecimiento of the material once that this has plastificado. They exist two types of endurecimiento, the endurecimiento isotrópico and the endurecimiento cinematic.

However, the models of mixed material that combine a law isotrópica with a cinematic law have received a special attention because of the capacity of improvement that offer in the prediction of the effect Bauschinger and of the behaviour cíclico of material. In the Figure 5 shows the meaning of this type of endurecimiento.

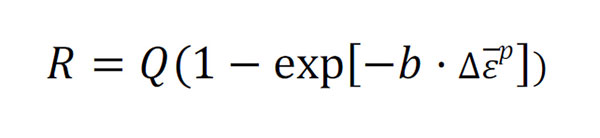

One of the most popular is the model of Chaboche and Lemaitre (1990). This model combines the law of endurecimiento isotrópica developed by Voce, by means of the introduction of the parameter isotrópico R:

Where Q and b are parameters of material and is the plastic deformation accumulated. And the cinematic law is entered by means of the cinematic law of Chaboche that defines the evolution of the backstress X through the following expressesion.

Where C and γ they are parameters of material and X represents the backstress.

4. Experimental procedure

As already it has mentioned previously, the numerical models are a very powerful tool for the dimensioning of installations of aplanado. In the present work has developed an able numerical model of dimensionar these installations taking into account the real behaviour of the material during the process of aplanado. To continuation expose the steps that it is necessary to realise, taking like example the dimensioning of an installation of aplanado for a steel of high elastic limit, TRIP700, with 1,5 millimetres of thickness:

- Characterisation of the material by means of an essay cíclico of traction-compressesion.

- Determination of the optimum parameters of the model of Chaboche and Lemaitre, by means of the adjust of the model to the experimental data.

- Develop of a model of able finite elements to simulate the process of aplanado.

- Introduction of the model of material found in the model of finite elements developed, for the obtaining of numerical results on the tensional state and of deformations in the sheet along the process and to the exit; as well as values of efforts and necessary moments in the rollers to llevar the process.

4.1. Characterisation of the material

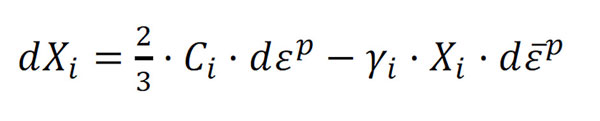

In the present work the steel of high resistance TRIP700 has been investigated with the aim to analyse his modelado in the process of aplanado pro rollers. The thickness of the samples has been of 1,5 milíemtros and to continuation presents in the Table 1 the mechanical properties of each material.

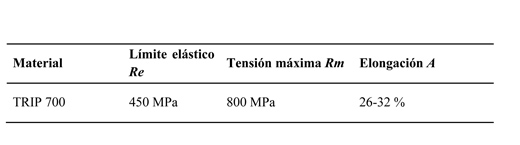

The essay cíclico of tension-compressesion has been llevar to realise the characterisation of the endurecimiento of the material. The team MTS Material Test System has been employed during the realisation of the experiments. The data of strength are purchased by means of a cell of axial load of the machine and the values of deformation are measured by means of galgas of small deformations to obtain a continuous measurement. The essay of tension-compressesion is simple and presents the advantage that they obtain values of tension-deformation directly, without need to realise reverse analysis. However, it exists a difficulty added since the probeta tends to pandear when it is subjected to compressesion. Thus it has designed a tooling to avoid the pandeo of the probeta during the essay. The Figure 6 sample the experimental team used. The probeta has been attached between two plates leaving a gap of 0,1 millimetres and has been lubricated with Rhenus Faith 1300 to delete the influence of the friction during the essay. One of the plates has a window where the galga is placed such as it shows the figure.

During the essay, the probeta has been subjected to 1 complete cycle, in which it has deformed 2 % to traction and -2 % to compressesion.

4.2. Identification of the parameters of the model of Chaboche and Lemaitre (1990)

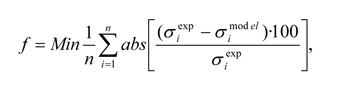

The identification of the parameters of the model has been realised by means of the minimisation of an objective function, defined like the difference between the value predicted by the model and the experimental data.

Where n is the number of experimental data, σiexp is the tension obtained in the experimental essay, and σimodthe is the tension predicted by the model.

4.3. Model of finite elements of the process of aplanado

Thanks to the development of a model of finite elements that simulate the process of aplanado by rollers, can have information of the progressive deformation that suffers the sheet from the start at the end of the aplanado, being a necessary tool for a good design and ensure the suitable aplanado final of the metallic band.

The numerical model has been created with Marc Software, by his experience in processes of conformed of sheet to analyse contacts and big deformations.

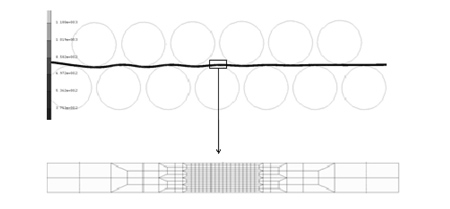

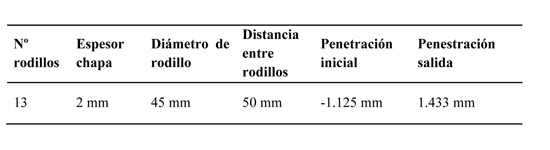

Besides, has estimated a time of lower calculation with this program that with other commercial programs of finite elements. The aplanadora developed in the model is composed with 13 rollers with an initial penetration of -1.125 millimetres and a final penetration of 1.433 millimetres. A coefficient of friction of 0,25 has been established for the process. The sheet has been discretizada using elements of 4 points of integration and the mayado employee has been developed with a no uniform distribution along the sheet. In concrete, a mayado finer with 16 elements in the thickness has been used in the central zone to obtain results more precise and stabilised, whereas a mayado more suffice has been used in the rest of the sheet to reduce the time of calculation.

The model has been created with 2 rollers of shot that are situated just before the machine so that these help to the sheet to move to the aplanadora. The figure 7 sample a diagram of the model 2D developed in the zone of the rollers of work and the geometrical specifications detail in the table 2.

5. Results

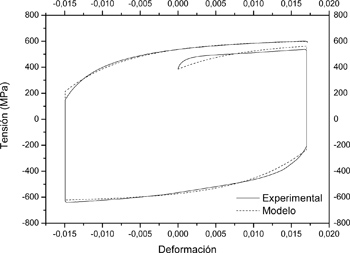

In this section present the experimental results of the essays of traction-compressesion, as well as the numerical answer of the model with an optimum combination of parameters.

5.1. Model of the material

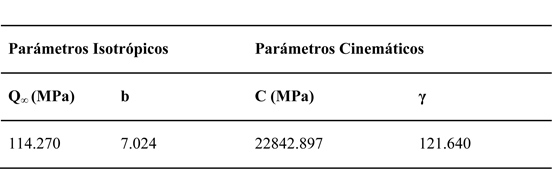

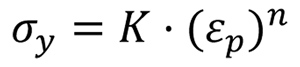

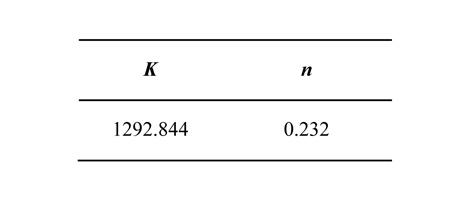

The mixed model of Chaboche and Lemaitre developed in the section 3, has been adjusted to the curves obtained during the essay of traction-compressesion by means of a method of optimisation. In the Figure 8 grafica the result of the adjust of the parameters of the model to the experimental data of an essay of 1 cycle, and in the Table 3 detail the parameters obtained in the optimisation.

In the numerical results obtained of the simulations, has compared the mixed model found previously with a model isotrópico pure, by means of a function with two parameters of the type:

Where K and n are parameters of the material. In the Table 4 show the values obtained of these parameters for the TRIP700.

5.2. Numerical results of the process of aplanado

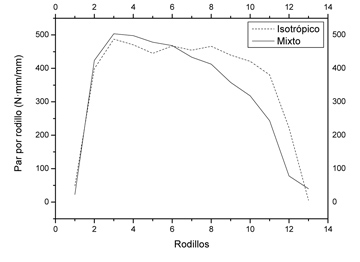

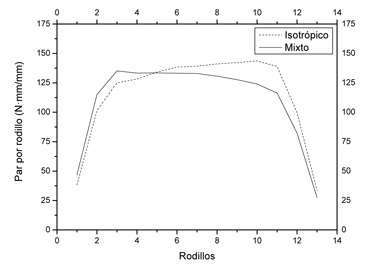

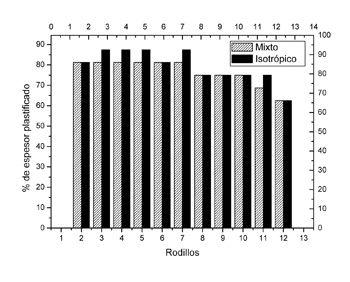

The values of the parameters of material for both models, mixed and isotrópico, obtained in the previous section have been entered in the model of finite elements to simulate the process of aplanado. In the Figures 9, 10 and 11 compare the results of obtained when the simulation has realised with a model isotrópico and one mixed. The values given of pair and strength by roller showed are N•mm/mm and N/mm respectively. This is due to that the model developed is 2D, therefore to obtain the total value would be necessary to multiply these values by the width of the sheet to aplanar.

Observes in the Figure 9 that both models present the same tendency regarding the necessary pair in each roller so that the sheet happen between them. The values reached go to depend directly of the coefficient of friction imposed in the simulation, that in this case is of 0,2, value established of empirical form like the necessary value so that the sheet was dragged by the rollers. In both cases reaches the maximum in the first rollers and afterwards falls quickly. This fact has felt since according to bibliography and the own experience of the manufacturers, seems that between the 3º and 5º roller is where reach greater values of deformation and plastification of the sheet, therefore the pair required is greater. However, the use of a model isotrópico in the modelado of the process predicts some upper values of pair with regard to the values obtained with the model of mixed.

In the Figure 10 present the vertical reactions of the rollers during the process. It appreciates a difference regarding the behaviour followed depending the model of material with which has realised the simulation. The model isotrópico presents an increasing pattern of strength in the rollers until almost the end of the process, whereas the mixed model presents again a maximum in the third roller, to go afterwards falling in the successive rollers.

In the Figure 11, shows the percentage of plastification reached in each roller. This does reference to the percentage of thickness of the sheet that finds plastificado in the go through each roller. In both cases has surpassed 80% of thickness plastificado. Said value has established like referent between the main manufacturers of aplanadoras, like the level of plastification that ensures a planitud of sheet to the exit of high quality.

6. Conclusions

In the last years there has been an increasing interest by the steels of high resistance because of his high resistance and reduced weight. These characteristic convert them appeals mainly in the car sector, where the manufacture of safe trucks, light and of low cost, has turned into one of the main aims of the sector.

Exists an important desconocimiento about the behaviour of these materials. Thus, it results of high interest realise a deep study of his behaviour when they are subjected to processes of aplanado, with the aim to optimise the process and obtain sheets of high quality for his back processed. By this reason, has selected the mixed model of endurecimiento of Chaboche and Lemaitre to predict the behaviour of the TRIP700 in place of a model isotrópico, by his capacity to predict the behaviour of the steels when they are subjected to efforts cíclicos of tension-compressesion and for being implemented in the majority of the codes of finite elements. This model has been able to represent some of the most important phenomena that give in loads cíclicas, like the effect Bauschinger and the endurecimiento of the material.

For the determination of the 4 parameters of clear-cut material in the model of Chaboche and Lemaitre, the essay of traction-compressesion has resulted to be a fast and easy form to obtain experimental data, by means of the help of a tooling designed to avoid the pandeo of the probeta during the essays.

Regarding the numerical results obtained in the simulations, fits to stand out the sobreestimación realised by the model isotrópico in terms of pair and strength by roller. These results involve problems to the hour to realise the design of the aplanadora, since the design dictated by a model isotrópico involves a greater cost in the development of a machine of big power, that according to the mixed model would not be necessary. The percentage of plastification reached with the configuration of machine established has been acceptable with both models for having surpassed 80% of plastification of the thickness in the 3º roller.

7. Future lines

The project developed provides a fully functional tool and useful for the analysis of the process of aplanado. Nevertheless, they exist still a lot of fields of improvement on which is working . Among others the validation of the model of numerical simulation with an experimental prototype of aplanado developed by Fagor Arrasate. The development of this prototype goes to allow know real values of strength and pair in the rollers, as well as the deformations suffered by the sheet during the process of aplanado by means of the sensorización of this. Of parallel form is developing a tooling that allow to determine coefficients of friction between a flat body (sheet) and a body curvo (roller), for like this realise the modelizado numerical with coefficients of real friction.

References

[1] B Engl, Cold Rolled HSLA Sheet and Strip Products, International symposium niobium, Niobium 2011, Orlando, Florida, USES, 2001, pp. 675.

[2] J Larrañaga, Geometrical accuracy improvement in flexible roll forming process by means of local heating, (2011).

[3] M Shi, X Zhu, C Xia, T Stoughton, Determination of nonlinear isotropic/kinematic hardening constitutive parameters for AHSS using tension and compressesion tests, (2008) 137-142.

[4] X Lemoine, L Durrenberger, H Zhu, R Kergen, Mixed hardening models: parameters identification on AHSS steels, Arcelor Mittal R&D.

[5] J Mendiguren, L Galdos, IS of Argandoña, And Silvestre. Ludwik's Model Parameter Identification for V-Bending Simulations with You64 and MS1200, Key Eng Mat. 504 (2012) 889-894.

[6] And Doege, R Menz, S Huinink. Analysis of the levelling process based upon an analytic forming model, CIRP Ann.Manuf.Technol. 51 (2002) 191-194.

[7] And Theis. Strip shape Control, Metalfomingmagazine. (2004).

[9] B Cox, Roller leveling 101, 2012 (2007).

[10] JL Chaboche. Constitutive equations for cyclic plasticity and cyclic viscoplasticity, Int.J.Plast. 5 (1989) 247-302.

[11] J Lemaitre, JL Chaboche, Mechanics of solid materials, Cambridge Univ Pr 1994.

[12] R Halama, J Sedlák, M Sofer, Phenomenological Modelling of Cyclic plasticity, (2012).

[13] To.P. Design, Levelling in detail, 2012 (2009).

[14] K Park, S Hwang. Development of To finite element analysis program for roller leveling and application for removing blanking bow defects of thin steel sheet, ISIJ Int. 42 (2002) 990-999.

[15] L Bodini, Or Ehrich, M Drauhausen, Heavy plate leveler improvement by coupling to model to to flatness gauge, 2012.

[16] L Cui, X Hu, X Liu, Analysis of leveling strategy for to plate mill, Advanced Materials Research. 145 (2011) 424-428.

[17] J ROBERTS, T SHEPPARD. Mechanics of Tension-Levelling Process, Journal of the Institute of Metals. 99 (1971) 293-&.

[18] J Bourgon. Levelling: modelling and Industrial applications, The Revue of Métallurgie - CIT. (1993).

[19] L Yan, B Snider, Reducing seturp time in strip leveling, 2012 (2008).

[20] RP Smith. The Effect of the Number of Leveling Rolls on the Straightening Process, IRON AND STEEL TECHNOLOGY. 4 (2007) 57.

[21] L Madej, K Muszka, K Perzyński, J Majta, M Pietrzyk. Computer aided development of the levelling technology for flat products, CIRP Ann.Manuf.Technol. 60 (2011) 291-294.

Gratitudes

The work presented in this article has been llevar thanks to the cooperation with FAGOR ARRASATE and KOONIKER, with the financials of the National Program INNPACTO for the public cooperation-private (Spanish Ministry of Science and Innovation).