The sector of the mechanised no lacking to his appointment with DMG Mori Seiki in Barcelona

In total, some 324 pertinent assistants of 243 companies, happened of the 6 to 9 March by the installations that the company has in Ripollet (Barcelona), mainly of the sector of the mechanised in general, followed of the sector of bar-cutting. Fruit of this interest, in the company pose centre the next days of open doors, foreseen for the month of May, in this segment.

No only machines

During the four days of days DMG Mori Seiki offered, further of the classical demonstration of the work of the machines, a series of conferences on diverse subjects of interest for the sector. For this had the participation of the Association of Moldistas of Catalonia (Ascamm) for the seminar on moulds, with Driven Main for the seminar on financial subjects and with Asfere Engineering to treat on the ‘read manufacturing'. Some days that attracted the interest of the assistants and that suppose a value more to the service of DMG Mori Seiki.

The high technology wins the game

The economic situation of the last years has done mella in the companies of the sector metalmecánico. However, some companies have been able to find an oxygen cylinder in the internationalisation and, more still, in the projects that require of high technology. Proof of this is that precisely the machines with equipment advanced are those that are having more demand, as it recognises David Gatell, “because they do pieces with value added, with which the customer obtains a greater profit and by which the companies are had to pay. And to realise these pieces are necessary machines of high technology”. And it is that the problem that face the companies “is only financial”, aims Gatell, “have been able to detect that the companies yes have work”. What would have to be a signal of alert to the competent administrations if they want to keep the alive industrial fabric for when the economic situation recover .

integrated Centres of milling and turning of high precision and efficiency

Between the machines that the visitors could see in the day were the centres of integrated of milling and turning NTX 1000, machines multiejes evolved from the class N and designed following the contributions of customers. These machines have an improved rigidity of the tools by means of the contact of the cone of the husillo and the brida of the tool, increasing his useful life, increasing the power of cutting and improving the precision of the mechanised. Besides, it incorporates a system of twist of fast axles, with holgura zero, with what the direct transmission of power to the rotary presses axles without using gears deletes games in the gear. On the other hand, the structure with Ram octogonal, to control the thermal sensors trip and offer a rectitud optimum: with the four guides situated in diagonal join them with regard to the others distort simétricamente in reply to the heat generated by the travel to high speed. This does that the centre remain in the same position, offering high speed and high precision in the advance. Likewise, the turret milling machines with integrated engine improves the capacity of milling. For this the engine is placed in the turret milling machines, with what reduce to the minimum the generation of heat and the vibrations and improves the efficiency of transmission. To his time, has improved the capacity of cut, the speed, the quality of the surface and the precision. The centres NTX include in addition to series a magnetic linear scale absolute (control of complete enclosed loop) to offer a positioning of high precision, with a resolution until 0,01 micras.

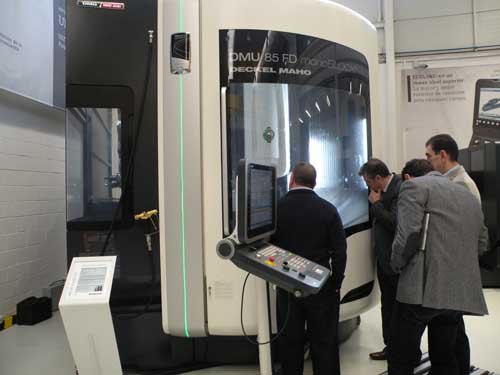

The new generation MonoBLOCK

During the day the machine DMU 85 FD MonoBLOCK was also centre of attention by part of the assistants. This machine of milling universal with five axles belongs to the new generation MonoBLOCK, a new concept headed to miscellaneous sectors like the mechanised simultaneous of 5 axles, milling of high speed highly dynamic, milling and turning, mechanised by start of shaving with high pair of twist or for the wide field of manufacture of productive pieces in three, maximum five, axles, covering sectors like the aerospace, the one of the power, the automotive sector, doctor or of tools. They are machines that stand out by his extreme rigidity and stability allowing reach the maximum level of performance in the milling and in the mechanised as well as a big level of precision. The structure MonoBLOCK supposes a high percentage of static mass in addition to a detailed analysis by finite elements (FEM). The MonoBLOCK are 50% more dynamic thanks to a car with weight optimised in X/And and a tool holders in Z of GGG60. It admits the possibility of paletización with access without limitations to the area of mechanised and ensures an optimum flow of shavings and evacuation of these to backwards, with box colectora of big shavings. The support on three points by means of the structure MonoBLOCK autorrígida and design of hook of crane for a set up extremely easy. In the standard model include systems of direct measurement. The load with crane without limitations goes from up until the centre of the table. Besides, it guarantees the maximum stability by means of big cojinetes YRT in the rotary presses table basculante and husillos of balls of big dimensions in all the axles. Besides, thanks to his compact structure, these machines require of lower space that the conventional.