Pieces injected with foam of high quality in the surface

Like one of the pioneers in the field of the technologies of innovative processes, Wittmann Battenfeld has been working acutely during a lot of years in the manufacture of light pieces which have to have a quality of flawless surface. For example, Airmould technology of injection of gas that already has been into use during a considerable time in the manufacture of hollow and light pieces and at the same time fulfil with the standards of high quality.

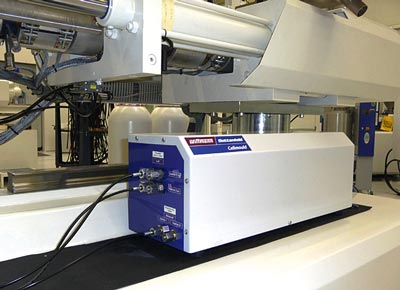

The process more recently developed by Wittmann Battenfeld is Cellmould, a process of physical gasification, by what the pieces of foam can produce with a compact shell and a structure of cell in the core. Wittmann Battenfeld Is the manufacturer of this technology and to his time of the machines of injection, both under a same mark.

The use of Cellmould allows the production of light pieces without parts sunk or deformations, since it contains an external layer that consists of enclosed cells.

This texture, however, does not go out entirely smooth, neither in sight neither to the touch, without the simultaneous use of a process to improve the quality of the surface.

BFMOLD For perfect surfaces

With BFMOLD, Wittmann Battenfeld has a process to his disposal that – in contrast with the moulds of conventional channels of temper – use all the zone directly behind the cavity for the refrigeration. Of this way, the pieces moldeadas have minimum and excellent deformations attributes of surface that can be produced inside a time of cycle very short.

But the fast cooling is not the only purpose for which this system of cooling in the outline is used. The warming of the cavity with hot water to pressesure also makes possible inside only some seconds. BFMOLD Therefore it allows the warming cíclico, variotérmico and the refrigeration of the cavity of the mould (using the water like half of control of the temperature).

With this process combined of temper of moulds variothermic and BFMOLD, now has arrived to be possible to satisfy the exigencias more strict regarding the quality of the surface of the pieces injected.

Wittmann Especially has developed his new series of Tempro plus D Miscellaneous thermoregulators that allow the practical application of this innovative technological process.

The cooling is perfectly uniform and, especially, extremely fast. The pertinent areas of the mould can attain with BFMOLD technology especially used for flat pieces. Like this BFMOLD is of interest no only to reduce the times of cycle, but also to minimise the tension of traction and therefore the prevention of alabeo.

On the other hand, the process variothermic practically deletes marks of sinking and that they are visible the conjoint lines, which is important especially for pieces with a visible surface or components of high shine.

Cellmould For light pieces

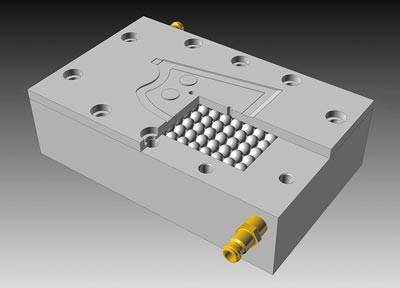

The process of foam structured Cellmoud allows the production of components extremely light with a high rigidity and without any type of marks of sinking. The agent espumante is nitrogen, that injects directly in the cylinder. A flow of gas regulatory module ensures a precise regulation and repetible of the injection of gas. They use special screws and barrels with a relation L/D 25, inside which the gas injected mixes and keeps dissolved and under pressesure. The mass melted that contains the agent espumante injects in the cavity, where the gas compressesed in the mass melted expands , fills up the cavity entirely and counters the volume of the contraction of the plastic material. Like this the gas does charge of the function of the pressesure of retention.

This translates in lower pressesures of filled and pressesures lower by cavity. Basically, all the types of pieces moldeadas of foam with a compact layer and a core of the cellular structure can produce with Cellmould, that is to say, the two parts of thin wall and of thick walls, however, this process is adapted for the production of light-weight in pieces of thin walls with a fine cellular structure and high resistance to the flexión.

Advantages of the process combined

No only the combination of Cellmould and BFMOLD produces perfect surfaces without need of costly processes of finishing, but it also offers a series of decisive advantages. In comparison with the production of pieces moldeadas compact, the time of cycle shortens here in more than a 10 %, since it can do without the phase of retention of pressesure required to long of the process of injection of plastic.

The reduction of weight attained by means of the process of learning of foam also reduces the costs of material.

In the fair Fakuma 2012, Wittmann Battenfeld did a demonstration of the advantages of this combination of special processes in the production of a cover of fixed telephone, during the exhibition in the stand 1204 in the pavilion B1. Thanks to the additional utilisation of BFMOLD and Cellmould the piece of foam could be presented with a perfect surface in “black piano”.

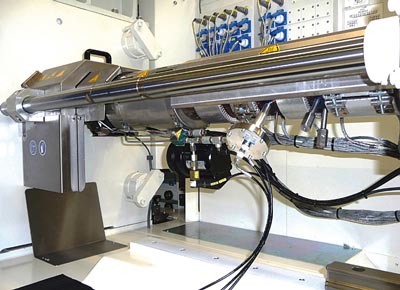

The surface of the piece moldeada is a complement perfect of the surface of the cavity, free of marks of sinking and visible lines of union. This part produces in a machine of iinyección HM 110/350 of with a mould of an alone cavity supplied by Kunststoffinstitut Lüdenscheid. The machine is instrumented for Cellmould with barrels with a relation L/D 25, also with a system of control Cellmould integrated cheese cheese in the system of the machine a control Unilog B6 of and flow of gas Cellmould regulatory module for the injection controlled of nitrogen.

The machine of injection is built like a privileged solution. Likewise it used a robot Wittmann for the retreat of the parts injected, a band transportadora, as well as peripheral team, all integrated cheese cheese in the frame of the machine. The pieces finished extracted and deposited in a band transportadora controlled by a robot W818 Wittmann, that also was integrated cheese cheese in the system of control of the machine.