Sequiplast XXI, S.L. - Extruders for manufacturing laminates, bobbins, films and others

Optiflow LP

The technology of 9 layers improves the capacity of production of film blown

Battenfeld Gloucester Engineering Co. It has sold several units of 9 layers Optiflow LP (die of low profile) and in the moment is installing a line of 9 layers for film blown with a die Optiflow LP in his laboratory of investigation and development that will allow to effect industrial proofs for current and potential customers. Ampac plastics Of Cincinatti, (EE.UU) is one of the manufacturers that has invested in the technology of 9 layers of Battenfeld.

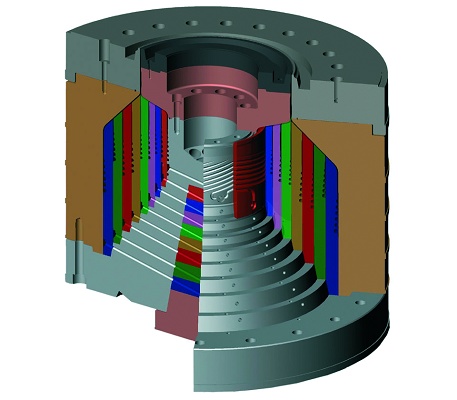

The most important component of the line of 9 layers of Ampac is the die of low profile Optiflow LP. Battenfeld Gloucester Has involved several developments in the design of the since they improve the manipulation and the exert at the same time that improve the quality of the film. The most obvious characteristic is the low profile. The dice Optiflow use a new design of concentric baboon. It incorporates a concentric baboon for each layer extruída. When it assembles the die, the mandriles go in one in the another, what reduces the height of the die in 50% in comparison with the traditional dice of design of plates (pancake).

Of the same way, the mandriles of espiral generate a positive effect in the flow of the resin because they reduce the time of residence of the material in the die together with a uniform flow without restrictions. The resins pump from the inferior part of the die and flow in shape ascending through the channels of transport designed by models of computer. Insertos In the ports of feeding of each baboon designed especially with radii of curvature softened improve the flow of the polymer and deletes the atascamiento of the resin.

The most important component of the line of 9 layers of Ampac is the die of low profile Optiflow LP. Battenfeld Gloucester Has involved several developments in the design of the since they improve the manipulation and the exert at the same time that improve the quality of the film. The most obvious characteristic is the low profile. The dice Optiflow use a new design of concentric baboon. It incorporates a concentric baboon for each layer extruída. When it assembles the die, the mandriles go in one in the another, what reduces the height of the die in 50% in comparison with the traditional dice of design of plates (pancake).

Of the same way, the mandriles of espiral generate a positive effect in the flow of the resin because they reduce the time of residence of the material in the die together with a uniform flow without restrictions. The resins pump from the inferior part of the die and flow in shape ascending through the channels of transport designed by models of computer. Insertos In the ports of feeding of each baboon designed especially with radii of curvature softened improve the flow of the polymer and deletes the atascamiento of the resin.