Roegele, S.A. - Thermoforming machinery

Method for in-line deep-drawing of small bottles: optimisation of costs of logistics, manipulation and until a 36 % in prime matter

The terms “eaten ready“ and “functional food” are inevitably joined to the image of a person drinking a yogurt or similar beverages of a small bottle. The tendency that has gone increasing does some time does not limit only to the yoghourts to drink, but it extends to a lot of sectors of the alimentary industry.

The current consumer does not want to lose his time eating with spoon, but yes take a snack cool and healthy of easy and fast way. For this reason it discovered the bottle of portions. With this bottle, the products are smart to be consumed directly from the fridge so much home as in the work, for sportive activities and games in his free time.

Up to now, these containers only produced by process of injection or blown.

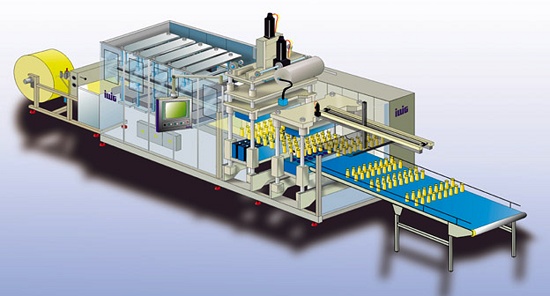

Since from the area of the termoconformado always has thought that this system involves a substantial reduction of costs. Illig, specialised in the manufacture of machines of termoconformado, has developed a method for the in-line deep-drawing of these bottles.

The moldeadora of bottles BF 70 can be operated like individual machine and also with a direct interconnection with new or already existent stations of filled and sealed. A high degree of freedom of design beside a very fast cycle and a line of performance makes possible the production of the bottle directly where produces the need. Of this form no only save costs of until a 36 % in prime matter, but also of logistics and manipulation.

The current consumer does not want to lose his time eating with spoon, but yes take a snack cool and healthy of easy and fast way. For this reason it discovered the bottle of portions. With this bottle, the products are smart to be consumed directly from the fridge so much home as in the work, for sportive activities and games in his free time.

Up to now, these containers only produced by process of injection or blown.

Since from the area of the termoconformado always has thought that this system involves a substantial reduction of costs. Illig, specialised in the manufacture of machines of termoconformado, has developed a method for the in-line deep-drawing of these bottles.

The moldeadora of bottles BF 70 can be operated like individual machine and also with a direct interconnection with new or already existent stations of filled and sealed. A high degree of freedom of design beside a very fast cycle and a line of performance makes possible the production of the bottle directly where produces the need. Of this form no only save costs of until a 36 % in prime matter, but also of logistics and manipulation.