DMG Mori Ibérica, S.L.U. - Centros de mecanizado verticales

Mecanizado completo: para reducir tamaños de piezas, plazos de entrega y presión económica

DMG ofrece todas las facetas para el mecanizado completo: el royalty del arranque de viruta y también la respuesta más económica para reducir tamaños de piezas, plazos de entrega y presión económica. El nivel técnico inicial requiere mecanizar en 5 caras/ 5 ejes en fresado y el empleo de herramientas motorizadas en el mecanizado en torno. Pero sobre todo, el "título más noble" se reserva para máquinas de alta tecnología para el mecanizado simultáneo en 5 ejes combinado la tecnología de fresado y torneado en una misma máquina.

Las máquinas que realizan el mecanizado completo deben su éxito a las ventajas económicas que les proporciona una cadena de proceso reducida. Se evitan transporte de piezas entre varias máquinas y por tanto el riesgo de daños, se reducen los tiempos de preparación, simplifican la planificación de la producción y reducen tiempo y coste necesario para la fijación y preparación de operaciones. Por tanto, las máquinas que realizan el proceso complete proveen el camino más rápido y económico desde el diseño hasta la pieza acabada.

El modelo DMU 50 es la referencia económica para iniciarse en el mecanizado en 5 ejes, y además permite entrar en una nueva era en relación a las condiciones de corte de herramientas, fijación de pieza y fabricación de moldes en talleres, centros de formación y laboratorios.

Tecnologías innovadoras y opciones como accionamientos digitales, mesa rotativa basculante controlada a CN con sistema de bloqueo hidráulico y controles de alta tecnología con pantalla TFT de 15" con software 3D caracterizan el impresionante rendimiento de esta máquina.

La DMU 50 se puede equipar con diferentes tipos de mesas y otras opciones que abarcan desde la variante simple de 3 ejes hasta el mecanizado en 5 caras. Con la DMU 100 monoBlock DMG ofrece un ejemplo de la gama de máquinas monoBlock con un rendimiento ilimitado y un alto grado de flexibilidad. Con cinco ejes controlados como equipamiento estándar, opciones de husillo desde 10,000 rpm a 42,000 rpm, cabezal basculante controlado como eje B con un campo de rotación de 150° incluyendo ángulos negativos de hasta 30°, y la rápida mesa rotativa CN, se expone la amplia gama de mecanizado económico universal con área de mecanizado de (X/Y/Z) 1.250 x 710 x 719 mm y para piezas de hasta 800 kg.

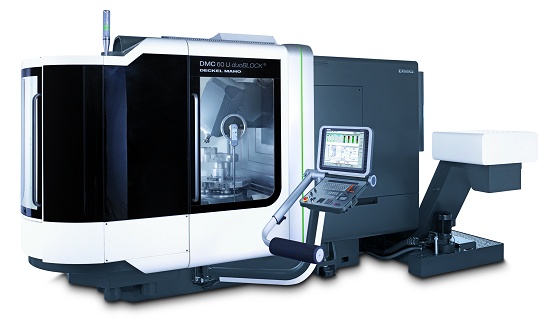

De la familia de máquinas duoBlock hay que destacar el centro de mecanizado universal DMC 60 U duoBlock. Equipada con un rápido cambiador de pallet para preparaciones paralelas fija un nuevo hito en el mecanizado a 5 ejes de alta productividad. El concepto duoBlock permite combinar productividad y mecanizado en 5 ejes gracias al rápido almacén de cadena y al cambiador de pallet rotativo así como la mesa rotativa CN de alta precisión y el cabezal basculante controlado a CN como eje B opcional. Áreas de trabajo amplia y de fácil acceso de 600 x 700 x 600 mm con mínimo espacio requerido es la clave de su diseño. Junto con el cambiador de pallet estándar, el modelo duoBlock incluye además como opción diferentes sistemas de almacenes rotativos para cuatro, cinco o diez pallets.

La HSC 75 linear y la HSC 20 linear convencen con su inmejorable dinámica y máxima velocidad gracias a sus motores lineales en todos sus ejes con una excelente productividad, precisión de contornos y calidad de acabado de superficie con una rugosidad de hasta 0,2 µm. Con una velocidad de giro máxima de 42,000 rpm en cada caso, la diferencia conceptual entre ambas máquinas es, ante todo, la integración de los 5 ejes. Para piezas de peso elevado, la HSC 75 linear se basa en una combinación de eje basculante en el cabezal principal y una mesa rotativa controlada CN, mientras que la compacta HSC 20 linear utiliza una mesa rotativa basculante equipada con accionamientos de alto par.

Las máquinas que realizan el mecanizado completo deben su éxito a las ventajas económicas que les proporciona una cadena de proceso reducida. Se evitan transporte de piezas entre varias máquinas y por tanto el riesgo de daños, se reducen los tiempos de preparación, simplifican la planificación de la producción y reducen tiempo y coste necesario para la fijación y preparación de operaciones. Por tanto, las máquinas que realizan el proceso complete proveen el camino más rápido y económico desde el diseño hasta la pieza acabada.

El modelo DMU 50 es la referencia económica para iniciarse en el mecanizado en 5 ejes, y además permite entrar en una nueva era en relación a las condiciones de corte de herramientas, fijación de pieza y fabricación de moldes en talleres, centros de formación y laboratorios.

Tecnologías innovadoras y opciones como accionamientos digitales, mesa rotativa basculante controlada a CN con sistema de bloqueo hidráulico y controles de alta tecnología con pantalla TFT de 15" con software 3D caracterizan el impresionante rendimiento de esta máquina.

La DMU 50 se puede equipar con diferentes tipos de mesas y otras opciones que abarcan desde la variante simple de 3 ejes hasta el mecanizado en 5 caras. Con la DMU 100 monoBlock DMG ofrece un ejemplo de la gama de máquinas monoBlock con un rendimiento ilimitado y un alto grado de flexibilidad. Con cinco ejes controlados como equipamiento estándar, opciones de husillo desde 10,000 rpm a 42,000 rpm, cabezal basculante controlado como eje B con un campo de rotación de 150° incluyendo ángulos negativos de hasta 30°, y la rápida mesa rotativa CN, se expone la amplia gama de mecanizado económico universal con área de mecanizado de (X/Y/Z) 1.250 x 710 x 719 mm y para piezas de hasta 800 kg.

De la familia de máquinas duoBlock hay que destacar el centro de mecanizado universal DMC 60 U duoBlock. Equipada con un rápido cambiador de pallet para preparaciones paralelas fija un nuevo hito en el mecanizado a 5 ejes de alta productividad. El concepto duoBlock permite combinar productividad y mecanizado en 5 ejes gracias al rápido almacén de cadena y al cambiador de pallet rotativo así como la mesa rotativa CN de alta precisión y el cabezal basculante controlado a CN como eje B opcional. Áreas de trabajo amplia y de fácil acceso de 600 x 700 x 600 mm con mínimo espacio requerido es la clave de su diseño. Junto con el cambiador de pallet estándar, el modelo duoBlock incluye además como opción diferentes sistemas de almacenes rotativos para cuatro, cinco o diez pallets.

La HSC 75 linear y la HSC 20 linear convencen con su inmejorable dinámica y máxima velocidad gracias a sus motores lineales en todos sus ejes con una excelente productividad, precisión de contornos y calidad de acabado de superficie con una rugosidad de hasta 0,2 µm. Con una velocidad de giro máxima de 42,000 rpm en cada caso, la diferencia conceptual entre ambas máquinas es, ante todo, la integración de los 5 ejes. Para piezas de peso elevado, la HSC 75 linear se basa en una combinación de eje basculante en el cabezal principal y una mesa rotativa controlada CN, mientras que la compacta HSC 20 linear utiliza una mesa rotativa basculante equipada con accionamientos de alto par.