DMG Mori Ibérica, S.L.U. - Tornos CNC

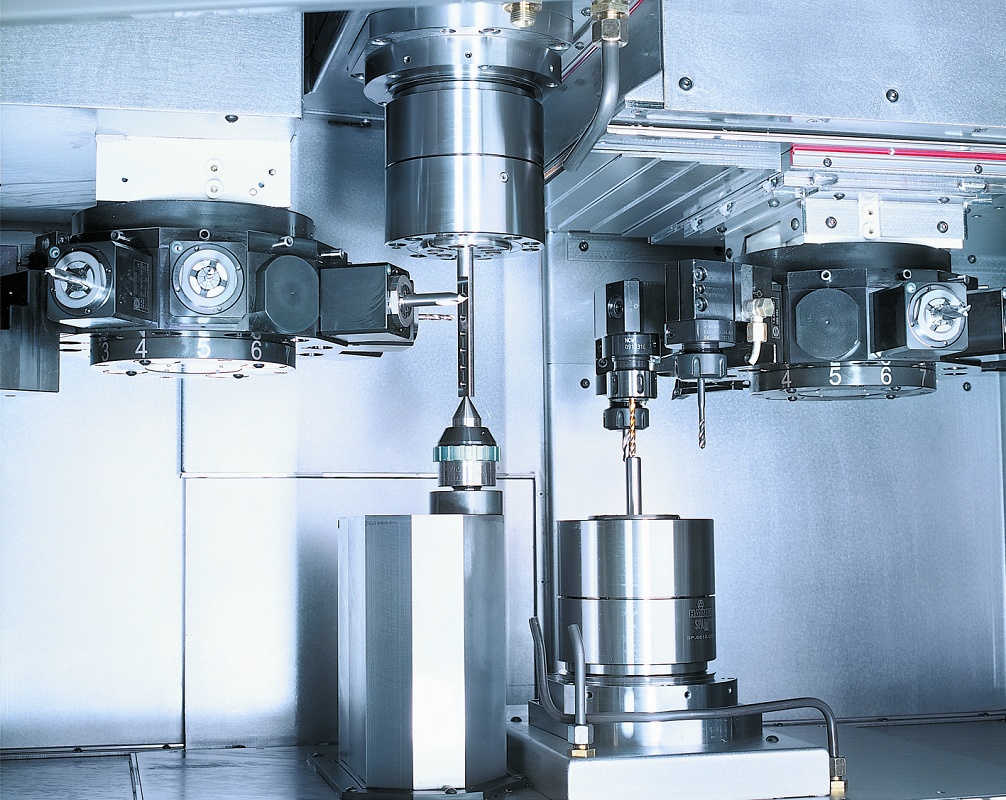

Gildemeister Twin

Tornos de doble husillo: hasta un 20% de potencia y ejes Y y B opcionales

La Gildemeister Drehmaschinen GmbH ha ampliado recientemente el concepto de espacio de trabajo de la serie Twin al campo de diámetros de barra mayores de hasta 102 mm. Todos los modelos disponen además de eje Y. Y tanto la nueva Twin 42 como la Twin 65 de mayor tamaño están disponibles opcionalmente con eje B para trabajos de fresado más complejos.

El concepto de espacio de trabajo, es debido en gran parte a la elevación transversal controlada CNC de 175 mm del carro de contrahusillo, sobre el que está construido el contracabezal. El contracabezal puede posicionarse, por tanto, en la línea central del husillo principal. Al mismo tiempo, la pieza puede ser mecanizada en acabado y esclusada hacia fuera por el revólver superior en el contrahusillo sin colisiones. La ventaja en productividad obtenible alcanza hasta el 20% frente a las máquinas de husillo doble convencionales, y abre con ello una nueva dimensión en el mecanizado completo en 6 caras.

También en los demás componentes las nuevas Twin ofrecen alta tecnología en estado puro. Por ejemplo, en los motores de husillo integrados de técnica sincrónica, que garantizan, con una potencia superior en un 60% a sus iguales de técnica asincrónica, mayores fuerzas de mecanizado en el campo de revoluciones superior. A ello se añade la enorme capacidad de eceleración y de frenada (del 0 al número de revoluciones máximo, los nuevos motores de husillo de la Twin 65 y la Twin 102 necesitan sólo 1,0 segundos). Y la Twin 42 consigue incluso un tiempo de aceleración o de frenada aún más corto.

Según la capacidad de barra se puede mecanizar con revoluciones de 7.000 min-1, 5.000 min-1 ó 3.200 min-1. El revólver superior y el inferior ofrecen cada lugar para las 12 herramientas accionadas y se caracterizan igualmente por un extremo dinamismo. Así, el tiempo de conexión de una estación a la próxima es de 0,14 s.

La denominación “powerline” se aplica debido a la aplicación de procesadores notablemente más rápidos del tipo Intel Pentium, y un rendimiento aumentado a causa de ello en más de un 100% en el campo CNC y PLC. Este control CNC, basado en Windows con ethernet Interface, cumple con todos los requisitos de la comunicación con redes subordinadas y el potente servicio internet de DMG.

Para la programación sencilla de piezas más complejas, Gildemeister ofrece el instrumento de programación externo MF Programmer 3D sobre base Windows. El espacio de trabajo de las máquinas Twin está reforzado aquí de manera tridimensional en el sistema. después de introducir los datos geométricos de la pieza a fabricar, ésta está disponible igualmente en 3D. Paso a paso se pueden programar con asistencia de un menú las distintas etapas del proceso en forma de ciclos. Después de la simulación a tiempo real con controles de colisión basta con apretar un botón para generar un programa CNC con tiempo de pieza optimizado.

El concepto de espacio de trabajo, es debido en gran parte a la elevación transversal controlada CNC de 175 mm del carro de contrahusillo, sobre el que está construido el contracabezal. El contracabezal puede posicionarse, por tanto, en la línea central del husillo principal. Al mismo tiempo, la pieza puede ser mecanizada en acabado y esclusada hacia fuera por el revólver superior en el contrahusillo sin colisiones. La ventaja en productividad obtenible alcanza hasta el 20% frente a las máquinas de husillo doble convencionales, y abre con ello una nueva dimensión en el mecanizado completo en 6 caras.

También en los demás componentes las nuevas Twin ofrecen alta tecnología en estado puro. Por ejemplo, en los motores de husillo integrados de técnica sincrónica, que garantizan, con una potencia superior en un 60% a sus iguales de técnica asincrónica, mayores fuerzas de mecanizado en el campo de revoluciones superior. A ello se añade la enorme capacidad de eceleración y de frenada (del 0 al número de revoluciones máximo, los nuevos motores de husillo de la Twin 65 y la Twin 102 necesitan sólo 1,0 segundos). Y la Twin 42 consigue incluso un tiempo de aceleración o de frenada aún más corto.

Según la capacidad de barra se puede mecanizar con revoluciones de 7.000 min-1, 5.000 min-1 ó 3.200 min-1. El revólver superior y el inferior ofrecen cada lugar para las 12 herramientas accionadas y se caracterizan igualmente por un extremo dinamismo. Así, el tiempo de conexión de una estación a la próxima es de 0,14 s.

La denominación “powerline” se aplica debido a la aplicación de procesadores notablemente más rápidos del tipo Intel Pentium, y un rendimiento aumentado a causa de ello en más de un 100% en el campo CNC y PLC. Este control CNC, basado en Windows con ethernet Interface, cumple con todos los requisitos de la comunicación con redes subordinadas y el potente servicio internet de DMG.

Para la programación sencilla de piezas más complejas, Gildemeister ofrece el instrumento de programación externo MF Programmer 3D sobre base Windows. El espacio de trabajo de las máquinas Twin está reforzado aquí de manera tridimensional en el sistema. después de introducir los datos geométricos de la pieza a fabricar, ésta está disponible igualmente en 3D. Paso a paso se pueden programar con asistencia de un menú las distintas etapas del proceso en forma de ciclos. Después de la simulación a tiempo real con controles de colisión basta con apretar un botón para generar un programa CNC con tiempo de pieza optimizado.