FANUC Iberia, S.L.U. - Robots and manipulators

Automation systems: for the wood industry

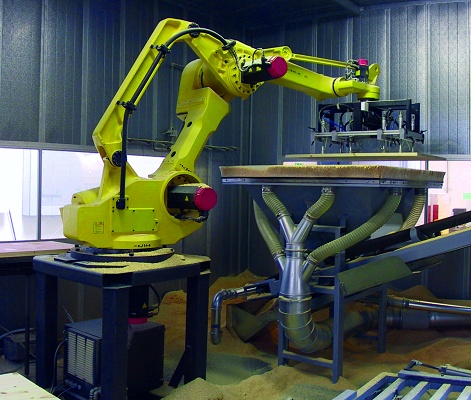

Thanks to the automation and robotics, the timber industry get a reliable, cost-effective solution to perform a wide range of tasks with a high precision and quality. In Europe Fanuc Robotics has developed strong expertise in the wood in the handling sector and polished chairs; Stapling in mounting of wooden boxes; palletising and de-palletising of shelves of wood; grinding of wooden shelves; and manipulated in machine tool (for serrated or logging).

With a range of products with capacities from 2 up to 700 kg, the company has the solution to your automation needs: robot palletizing M-410iB (4-axis, from 160 to 450 kg load capacity) is the ideal solution for palletizing large wooden pieces. Also, the new version of the robot R-2000iB runs perfectly complex tasks of handling thanks to its 6 flexible shafts, load capacity from 125 to 210 kg and reaches between 2.6 and 3, 5 m. Series M-900iA (up to 700 kg) allows the manipulation of very heavy parts. M-16iB and the new series M-710iC (up to 70 kg load capacity) offer a very rigid for applications of cutting or polishing arm. Along with the Force sensors of Fanuc, these robots reach a greater precision.

The series of painting robots can paint parts of all sizes. Vision of signature solutions will improve accuracy and enable automatic operations such as bin picking.

With a range of products with capacities from 2 up to 700 kg, the company has the solution to your automation needs: robot palletizing M-410iB (4-axis, from 160 to 450 kg load capacity) is the ideal solution for palletizing large wooden pieces. Also, the new version of the robot R-2000iB runs perfectly complex tasks of handling thanks to its 6 flexible shafts, load capacity from 125 to 210 kg and reaches between 2.6 and 3, 5 m. Series M-900iA (up to 700 kg) allows the manipulation of very heavy parts. M-16iB and the new series M-710iC (up to 70 kg load capacity) offer a very rigid for applications of cutting or polishing arm. Along with the Force sensors of Fanuc, these robots reach a greater precision.

The series of painting robots can paint parts of all sizes. Vision of signature solutions will improve accuracy and enable automatic operations such as bin picking.