Parallel kinematics prepared to succeed in the market of machine-tool

Interest in the technology of parallel kinematics to overcome these problems emerged in 1994, although the underlying principle had been described three decades earlier. Fundamentally, a parallel kinematics mechanism is a platform mounted on a series of telescopic arms of independently adjustable length. The hexápodos of parallel kinematics - or Stewart platforms - are used for a time in flight simulators and more recently in virtual reality attractions, where their ability of rapid movement and Acceleration with up to six degrees of freedom easily deceived human senses.

Pooling of European knowledge

The three year initiative presented within the framework of the Growth of the fifth framework programme of the EU programme, involved twelve partners from the scientific and industrial area of five different European countries. Completed in January 2003, includes the entire sequence from the initial design, through manufacture, to the implementation in several industrial sectors.

Real-time control

"In a machine in operation, these"kinematic transformations"must be carried out at intervals of 2 milliseconds to get the translation and acceleration required." Determine the mathematical basis for this control in real time, and for the calibration and compensation of the error in individual machines has been one of our greatest challenges. But with the methodology developed, we can easily adapt to different types of machine.

The manufacture of the machine itself is, on the other hand, relatively simple-, although it has been necessary to develop special parts as together arms and motors.

Multiple combinations

A set of tools design and virtual simulation of the behaviour made in Mach21, allow themselves the development of multiple machines in parallel kinematics of industrial relevance. They can also help to improve the performance of conventional architectures in series, allowing even more widespread application.

Positive results

- Handling heavy pieces (automotive industry)

- Horizontal milling 5 axes (aeronautical industry)

- Vertical milling 5 axes (sector of mold and matrix)

- Sheets of carbon fiber fabric. (textile)

Also has been a fifth virtual prototype for the Assembly of aircraft skins in structures of ribs and largeros (aeronautical industry)

"The project has produced a large number of positive results", says Sebastian. "There are three patents pending." Fatronik and collaborating centres have built a solid base of knowledge and information that may be shared with the world of industry. Participating manufacturers of machines and components have an advantage in what promises to be a major new market for machines. And business users will benefit from the rapid incorporation of technology in their manufacturing processes.

"This puts Europe in a strong position of leadership, and is clearly aligned with the current strategy of improving the capacity of us." It should generate additional employment, satisfying both the demand for machines and their use for the efficient production of products of high technology for major industries. "We hope to continue our research, in order to make a second generation of machine around 2015."

Members

Fatronik is responsible for the coordination of the project and the implementation of various technical tasks standing out among them measures to design, build and evaluate solutions of parallel kinematics for its implementation in the aviation sector. In particular, within the project, Fatronik develops parallel kinematics module Hermes, which is being implemented in different industrial solutions thanks to the vocation of Fatronik broaden and extend this development to different applications.

This is to respond to the latest programme stresses that demands the world market for machine tool in the field of the aeronautical sector and with the current solutions on the market are not possible to get.

Industrial implementations of the Hermes module:

- Space 5H: Fresadora horizontal oriented to the mechanised of structural piece inside the aeronautical sector component manufacturing sector component manufacturing sector treats of a hybrid machine with axles in series for the longitudinal and transversal courses and a module of cinematic parallel.

- Centre of mechanised vertical of high speed in 5 axles with possible application in distinct industrial states: aeronautical sector component manufacturing sector component manufacturing, moulds…. Customer: Ecole Centrale of Nantes.

The machine composes of a module of cinematic parallel and a table of double twist (pivotamiento and rotation).

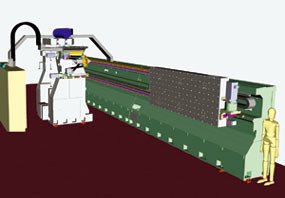

- ”Torres Paralell Kinematic System (PKS)”: Machine for the processes automated of taladrado, milling and remachado of high speed and high efforts in the manufacture and assembled of aeronautical sector component manufacturing sector component manufacturing structural components. Customer: MTORRES. This machine exposes in the EMO

This machine arises of the agreement of collaboration signed in the 2001 between Mtorres, company of wide experience in the design and the manufacture of systems for the automation of processes in the aeronautical sector component manufacturing sector component manufacturing sector, and Fatronik in the terrain of the cinematic parallel applied to the industrial processes. The aim of this Agreement roots in the development of a technological field taking advantage of the complementary capacities of both companies and his positioning in the market.