Last generation for most modeling exemplary logistics

July 26, 2010

The success story began in the Valley of Steyr, Austria. Lindinger family operated a food shop and his son, Friedrich Lindinger, fascinated by the model of aircraft, was able to convince his parents to leave two meters of surface of shelf for the sale of aircraft models.

Due to the increase in demand, the surface finally occupied all of the business, from being a store of food to a small company called Modellbau Lindinger GmbH.

In 1994, the family took the decision to move the business to a building of factory near the center of Molln, Austria, to devote himself exclusively to the trade of modeling. After some work adaptation and an extension, was born there the first store with approximately 1,000 square metres of sales as well as a center of modern shipping.

Due to the increase of customers, in the year 2007 opened a new store in the Mall Plus City in Linz, Austria. Meanwhile, the offer included sailboats, motor planes, helicopters, models of cars, engines, remote controls as well as all kinds of accessories. This variety was due to the various providers of international brands.

It soon became obvious that the only solution to meet the increasingly demanding requirements was a logistics centre. Therefore, the company Lindinger started to engage in the planning of a complex logistical concept.

The Logistics Centre

The main objective was smooth processes, interaction between the sale in store, selling over the phone, ordered by Internet, delivery of orders to large customers as well as the processing of the international service, all this from the same company. Approximately 15,000 articles should be desalmacenados effectively on the orders of picking, also appreciating the ergonomics of the jobs. The biggest challenge was to combine pleasant and good comfortable business rooms with a complex logistics center. For the first time, the processes should be automated and the picking done without papers.

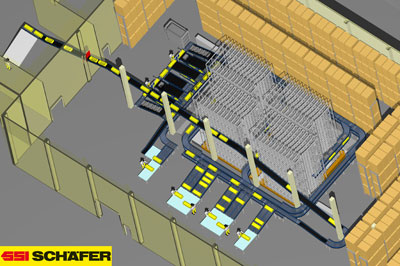

In Inzersdorf bei Kirchdorf, Austria, built a modern building composed almost entirely of glass and equipped with the most advanced technology. It even has an airport where customers can demonstrate their skills with the new models acquired under professional guidance. Next to the building business and directly connected to the business, is the central element of the logistics facility which was carried out by SSI Schäfer.

The system of picking automated system of continuous transportation of containers is composed of four 'commissioner' or fully automated picking equipment that stored the goods vertical and horizontal. These machines guarantee the availability of very small articles.

The continuous transport system simultaneously moves up 1,200 containers per hour towards two independent picking stations where the merchandise is collected through a beam of light and is her again positioned in destination containers. From there the goods is transported in a totally automated way to the location of packaging where its preparation for the shipment takes place. Distinguishes between short long (up to 1.2 meters) and container containers (approximately 0.6 meters) and can the two types present a division of up to eight modules.

The milestones

The synchronization of the automated processes of picking with the parallel manual storage machine was an essential requirement. The goal was a process automated via software to control from the receipt of goods until the final package packaging, thus facilitating the processing of up to 700 orders a day. In addition, the store has a direct connection to the logistics system for its replenishment.

To make picking online for orders qualify the range of products according to dimensions, rotation, as well as size of pieces. Thus, it is possible to assign the optimal picking locations in automated and manual store. The special challenge was the development of a highly dynamic concept that facilitates the picking of goods statically. Sophisticated control principles to launch the correct processes through complex calculations in the Host system. It was necessary to accomplish this task for approximately 15,000 different, large to very small items, taking into account sales conditions changing constantly, as well as a range of articles to grow quickly.

Currently, receipt of goods as well as manual and automated order picking are very accurate and accurately. It uses 'pick-by-light' and 'Put-to-Light picking', illuminations of racks of shelves that illuminate the correct modules as well as a 'furniBOX' (roll special container) for the multi-client picking. In addition, installed a shelf by gravity in the location of picking with pick-ups of goods guided by light. Tours of trainers with manual scanners is optimized for the picking 'man to goods'. In addition, an operator deals with the replacement of the picking locations and transports the recently received from the location of receipt of merchandise goods to storage locations. Similarly, generates new containers, which are filled in picking machine.

It is possible to repack the goods without limitations and simultaneously in five locations of packaging in client packs and prepare them for shipment. Shipping and billing documents are printed in time in the corresponding job.

A change of such impact only can succeed provided that all employees work together with the new model of work. At the end and the place must get used during the day to day to a new location and environment of the software. We managed to perform this step complicated with great success as a big family and highly motivated.

Finally, the logistics facility was put into full operation in December 2009. In January 2010 the store moved to Inzersdorf Kirchdorf bei.

Currently, the Modellbau Lindinger GmbH is a distributor of model articles of all of Europe's largest and caters to international customers. Through the partner company, SSI Schäfer, this takes place with efficiency without commitments.