This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

El PET continúa siendo la primera opción en el sector bebidasThe amount of PET bottles produced will increase seven per cent per annum until 350 billion units in 2009

The PET continues to be the first choice in the beverages sector

Drafting Interempresas10/07/2008

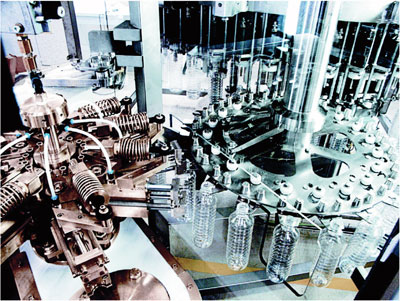

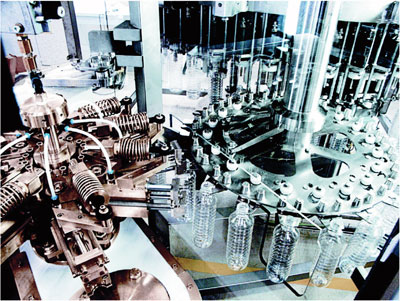

In the beverage industry, the plants bottling occupy entire buildings, so that a failure in a single component can affect the performance of the entire facility. Bottling machines and bottling manufacturers familiar with this problem and why work continually to develop solutions that take up less space and are more profitable.

The flexible top-loading machines allow packing the packs directly into boxes for transport. Photo: Gerhard Schubert GmbH

In the industrialized Western countries, the market of bottled mineral water continues to grow while the quality of the water that comes out of the tap is good. On the other hand, beer consumption has stagnated even at Brewers country par excellence, such as Czech Republic, Germany, Great Britain and the Benelux countries. At the same time, is open to manufacturers of bottling machines new markets with great potential and spectacular growth rates, as it is the case of China, the India and the countries of the former Soviet Union. Both beer and mineral water are very demanding products and, increasingly, in many regions of the world chooses to sell them in PET bottles. According to estimates by the London company of Euromonitor market research, the amount of PET bottles produced will increase seven per cent per annum to 350,000 million units in the year 2009 (2006: 288,000 million). Profitable manufacturing of PET containers, therefore acquires more and more relevance.

In the run-up to interpack 2008 (Düsseldorf, from 24 to 30 April 2008), main machinery manufacturers have decided to integrate in a single installation of stretch machines and the bottling. In this way give response to the demand of many enterprises bottling further extend its capabilities without implying a large consumption of space. The latest trends in the manufacture of PET bottles - without doubt the most popular non-returnable containers focus on reducing the weight and saving material.

Integral systems: disappear the lungs

Integral systems of production and filling of PET bottles are a very cost-effective solution, since the direct combination of the stretch machine and filling machine offers numerous advantages. While it is true that the bottles have the time to cool down as they pass through the course of transport that makes lung, in tours complexes with many curves and differences of height can cause jams, which in turn cause problems or interruptions in the transport.

Integral systems of production and filling of PET bottles are a very cost-effective solution, since the direct combination of the stretch machine and filling machine offers many advantages

These problems often cause the stretch machine production stops, which it ceases to work efficiently and therefore reduces the performance of the entire line. The integrated system ends with this problem, given that the effectiveness of the installation is determined exclusively by the stretch machine and filling machine. If there is any irregularity, latter communicates with the blow-moulding machine connected, and the system of command decouples both machines, then emptying machine stretch. Preforms them as charged end up passing through the area of heating and closed bottles is discharged by means of a conveyor belt.

For bottles for carbonated beverages, they come out of the machine of stretch to an approximate temperature of 75 ° C and must be cool to about 55 ° C. Comprehensive facilities, for example, an integrated washer is responsible for reducing temperature rinsing the inside of the bottle. In some cases, even a special cooling system of the base in the area of transfer of the bottles to the filling machine can eliminate the need of a washer.

The coupling of stretch machines filling machines allows to eliminate the lungs.

Even lighter bottles

Another current objective of the manufacturers of preforms and machinery is getting increasingly low weight. Reducing the consumption of material used, above all in the ring support, for example allows a considerable cost savings in the departure of purchases. The use of the flexibility and the shape of the plastic memory is one of the trends in vogue. A 500 ml PET bottle only weighs 9.9 grams and, thanks to the flexibility and the effect memory, the bottle recovers its original shape after compress. When it is reduced the weight of a bottle, it is usually reinforced with a number of cavities making it rigid, with which there is a danger of breakage and is, therefore, a limitation in reducing weight. On the other hand, if the bottle is flexible, these recesses can be eliminated. Thus, despite the reduced weight of the bottle, it is possible to choose freely the way to the packaging, make that the surface does not slip and keep within limits the noise that makes the bottle to crush it. Thanks to the memory of form, the bottle optimally supports the efforts that are seen during the transfer, packaging and transport processes.

Containers manufactured by deep drawing

Until now, the blow molding was the only technique that offered the proper molds to manufacture mini bottles used for the marketing of dairy products (e.g. yoghurts) in the field of "functional foods", a market in strong expansion.

In this sector, generally, bottles are purchased to a third party and are then filled and cover with appropriate machines. Blow molding machines manufacturers have adapted their designs to the needs of this segment and will present numerous examples of this new generation of machines in the next interpack 2008 in Düsseldorf. Today, for example, 65 ml containers are manufactured with moulds of 12 cavities and can reach a level of performance of approximately 4,600 units per hour.

In the case of multi-layer packaging, on the other hand, several extrusion machines are used to form an intermediate layer with barrier function. Systems for the rapid change of the mould-blowing and integrated leakproofness tests have also been developed.

Another novelty is a termoconformación that allows to manufacture the containers through deep drawing in line. These new procedures of termoconformación allow to obtain a thickness of totally uniform wall despite the small size of the surface of departure and the great depth of drawing.

Differences between blow-moulded bottles and the termoconformadas are not appreciated at a glance. If we put them in a scale, however, termoconformadas bottles weigh only half that of the molded blow and have in addition the stability that the market demands. The design of the thermoforming machine is based on the experiences compiled with FFS (formed, filled, closed) systems and vessel-moulding machines. The machine can be connected directly to the filling machines and closed in dairies, for example. The installation works at a speed of 25 cycles per minute, with 20 bottles per cycle. This is equivalent to a total of about production of 30,000 bottles per hour, the same as a filling facility and closed conventional.

For bottles for carbonated beverages, they come out of the machine of stretch to an approximate temperature of 75 ° C and must be cool to about 55 ° C

The flexibility and the memory of form of the material allows to further reduce the weight of the PET bottles.

The possibility of enfajar bottles on the way between the moulding unit and the press. For the later decoration, rather than a strip can also be used a label roll. This option is less expensive, but it requires that the bottles are available online and can not be used with bottles with a concave profile in the Middle, as the material of the label only supports contraction.

Another advantage of termoconformadas bottles is the external flange, which provides a surface to close flat. The flange of the bottles manufactured by molding blow is oriented towards inside, it is quite unstable and can cause problems during sealing.

Today, for example, 65 ml containers are manufactured with moulds of 12 cavities and can reach a level of performance of approximately 4,600 units per hour

Flexibility in the form of pack

Today, so if it's liquid yogurt, soft drinks or beer, bottles not usually sold loose, but in form of packs. Since the introduction of the compulsory for disposable packaging deposit in Germany, reusable containers for soft drinks and beer production has risen markedly. The packs of six units not only help the customer to carry their purchase, they also allow to combine different beverages in a package.

A top-loading compact Wrapapac allows working with packs of bottles, packages with handle, folding boxes, enveloping cartons and enfajados articles, as well as to define the number of units per package with total flexibility according to the existing needs. If the installation is completed with a scanning system, can also make combination packs of different flavors.

Switching between bands of six units and folding boxes with 20 bottles is performed in less than five minutes, and the compact dimensions of the packs Wrapapac confer on installing a high degree of flexibility and efficiency.

All the drives and movements are controlled by CNC system. A touch screen lets you see all data and central functions of the installation and management helps the operator.

The exhibition interpack 2008 will take place from 24 to 30 April in the city of Düsseldorf and she can see a wide and varied sample of innovative solutions and services for the industry of candy and all those industries with packaging needs, especially that of drinks.