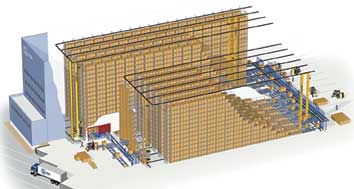

SSI Schäfer carries out "the project of the century" for the pharmaceutical industry in Eastern Europe

The Slovenian pharmaceutical company Lek, known internationally and with headquarters in Ljubljana (Slovenia), has been awarded to SSI Schäfer planning and implementation of their complex distribution warehouse. This project of great dimension, includes on the one hand, the installation of a warehouse of high altitude in Strykow, Poland, and on the other hand, the redesign and reconstruction of existing high-rise of the same store headquarters central of Lek, in Ljubljana, Slovenia.

The main feature of these two projects is the development of a system of maintenance that would be able to adapt to the usual requirements of cleaning in the pharmaceutical industry, as well as allowing efficient and automatic access to a wide variety of products.

It is to comply with this last objective that SSI Schäfer has provided each stores of high altitude with a change of aisle racking system.

The client

The Polish delegation in Strykow, near Lodz, has been chosen as the main hub for the production, storage and supply in the economic area of Eastern Europe.

The high volume of investment carried out in recent years in the community of Strykow, in addition to this new large-scale project, classified as a "project of the 21st century" by the management of Lek, have turned the city into one of the centres of production and logistics Eastern Europe's most modern. In the logistics complex, which stretches over an area of 25,000 m2, administrative buildings, development laboratories, production lines, and high-rise warehouses were installed in record time.

Objectives

(v) optimize and automate the flow of material to reduce the error rate to zero.

(v) reduce the costs of storage

(v) improve the quality of the supply of Lek and increase the effectiveness of the processes of warehousing, distribution and delivery through a quick availability of the stored products.

The project

The greatest challenge

Main feature: technology for clean rooms

Therefore, the main feature of this project lies in the development of a system of maintenance to meet increasingly stringent cleaning standards imposed by the pharmaceutical sector in manufacturing processes.

To accomplish this, SSI Schäfer has developed a technology especially suitable for clean rooms and it has been installed in some areas a maintenance system equipped with a smooth surface, of chains free of maintenance and equipment especially suitable for dirt-free environments.

In addition, to prevent the entry of particles within the areas of production, SSI Schäfer has integrated air barrier systems for depression by dragging the particles outwards from these areas. In this way, the raw material comes to production without having been contaminated.

Warehouse management system

However, the operation of the ANT in Lek software, has been limited to the central areas of control of material flow, preparation of orders, and visualization.

ANT is connected to the existing SAP of the client, which deals with strategies for storage of raw materials, semifinished and finished according to customer's special requirements.