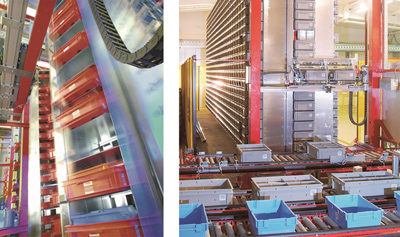

50% more than compactación of storage with Schaefer Carousel System

This system supposes, between other advantages, the guarantee of a short time of implementation as well as a high quality of the manufacturing of requests based in the exclusive system of guide for the user. It treats of a system whose installation saves space and resources and of flexibility practically boundless regarding variety of articles.

Containers designed for the system

The system SCS standard consists in four carruseles, each one of which has an independent automatic unit of load and download. His dense structure saves space and provides a capacity until 6.000 containers with a standard system of 4 carruseles. The corresponding containers can divide in a maximum of 16 compartments and have a maximum capacity of storage of 25 kilograms.

These cubetas of storage are handled by elevadores entirely automatic with his corresponding devices of load and extraction equipment equipment. The devices of extraction equipment equipment of the elevadores extract the cubetas of his locations in the one of the carruseles of the four corridors and deliver them to the circuit of integrated cheese cheese transport (loop). This ‘loop' carries the cubetas to the places of picking. The consequent decoupling of the movements allows to bend the cycles of storage/extraction equipment equipment of the elevadores regarding the conventional systems employees in the market. Besides it allows to integrate the activities of reaprovisionamiento in the operations of picking without interruption any.

- Control and software of warehouse

- Until 6.000 locations

- 4 elevadores

- 4 carruseles

- Put of picking

Performance

- Until 1000 double cycles (storages/extraction equipment equipments) by hour

- Gestión of existences in real time

Positioning / layout

- Possibility to position the modules to 2 levels

- Ring of picking: possibility to position it frontal or lateralmente

- maximum Height of the system 4,9 metres

- Wide of the system 10,5 metres

- Length of the system 10,4 – 15,9 metres (incl. Road of transport and elevador)

- Surface (6.000 cubetas) 166 m2

- Speed carrusel max. 0,6 m/s

- Acceleration carrusel max. 0,2 m/s2

- Performance carrusel* 250 double cycles/h

- Performance system* 1.000 double cycles/h

- Size of cubeta max. 600 x 400 mm, several heights

- Weight of cubeta max. 25 kg

- Pressesure on the losa aprox. 1.000 kg/m2

- Improves of accionamiento, carrusel + elevador 8 kW

*in function of the length of the corridor

Thanks to this optimisation of the processes of work, the tax of picking by each operario can elevate until 1.000 picks by hour, while the tax of errors of picking reduces until almost zero. In the station of work can develop all the functions of a warehouse: manufacturing of requests, entrance of commodity, gestión of returns, inventory and other activities of gestión of articles.

Particularly apt for big articles, weighed and/or sensitive, with a high performance, ergonomic and without errors. The articles are deposited directly in the cubeta of request.

Picking decoupled of the cubeta of request, where the products deposit in a funnel manifold. It uses for light and apt products so that they can be left fall from some height.