Optical and biochemical technologies to improve the systems of quality in the sector agroalimentario

In this line of work, the technology centres

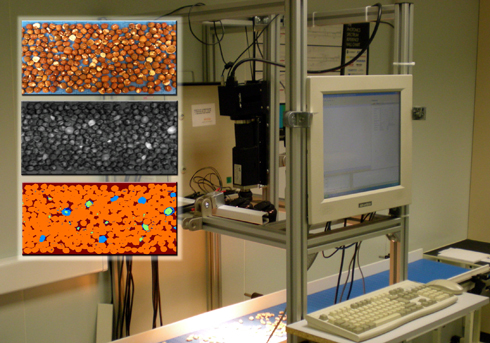

The aim of the project Optifood-Organic is, therefore, identify applications of this to scale industrial technology, reason whereby go to investigate and to develop systems of inspection of spectral vision to scale macro to improve the control of alimentary processes, as well as able optical devices to detect waste or contaminantes to scale micro. Later, they will realise essays with the systems developed with real samples of the cases selected.

- Of which form can help the optical and biochemical technologies to improve the control of production in the industry agroalimentaria?

In the actuality the companies already realise routine analyses in the control of the quality and of the hygiene of the foods that elaborate, but alas no all the problems in which have needs of control are resolved. There are a lot of companies that do not find suitable technologies in the market, thus in this project pretend to cover these gaps evaluating new technologies to tackle these problems. We are referring us specifically to optical technologies, that have the advantage to be very fast to apply, by the high speed to which propagates the light, and to the interactuar with the foods can evaluate his characteristics of a very agile form and no invasiva, processing and obtaining an information of quality and of hygiene quickly.

- In which appearances are collaborating Aido and Ainia in the project Optifood-Organic?

Aido is a centre of reference in optical applications, and therefore has a big experience in optical technologies of control and measure. On the other hand, here in Ainia are referent in the feeding, with a wide bagaje in the characterisation and the evaluation of the properties of the foods. The alliance between the two centres allowed to evaluate optical technologies applied in the alimentary sector. In fact, the technologies that are posing to apply in the project need of these two components. On the one hand, have a thorough knowledge optical technologies like the biosensores optical or the vision hiperespectoral with the peculiarities of the foods, and how interactúa the light and the photons with them, and therefore in his measurable properties (contaminantes or attributes of quality).

- Of which form will be able to apply the companies these advances and in which measure will allow them improve his products to level of quality and reduce costs?

In this project do not evaluate only some technologies, but also give the step to build prototypes that allow to show and test that these technologies work in real conditions of process and that they can be implanted in the productive processes of the companies. By the fact to be fast technologies and no invasivas are relatively easy to apply on line, well for a control of 100% of the production, if we speak of technologies applied to measure macropropiedades of the products, or also to measure properties nano or micrométricas to treat to delete contaminantes or waste that can have in the foods. The fact to do this work with optical technologies allows to realise this to a big speed. The advantages for the companies is that when can do fast and routine analyses go to obtain a tool so much to optimise the control of process, detect any problem of quality and hygiene the before possible with such to correct it or delete of the chain this no apt product, and guarantee that what goes definitively to expedition is safe and apt for the consumption. Therefore, it reduces in analytical costs, in losses by mermas, in costs of reenvasado, etc.

- Could explain an example of practical application?

One of the main current worries of the alimentary industry is the detection of odd matters that can enter accidentally, well in the prime matter or during the productive process. We are speaking of odd matters that do not have at all that see with the composition of the product that goes to pack and commercialise: rests of plastic, shavings of metal, rests of bone, the seed of a fruit, etc. The optical technologies allow to obtain maps of composition of the product that is processing. In the moment that appears an element that has a different composition to which has to have the final product, detects, and expels this product in concrete of the chain.

Another application would be the detection of chemical or sensory properties, for example, in products cárnicos. In the measure that a product have more fat that it deberia have, when realising a measurement in continuous can refuse this product. This control also allows so much in the alimentary industry like pharmaceutical ensure that each product that pack go with the active principles programmed.

-Which terms has the project and when will begin to realise the essays with the systems developed with real samples?

In these moments are realising already essays with real samples in pilot plant, but along 2013 will begin to work with equipment demostradores that allow to evaluate in real time the capacity of this type of systems. A fundamental work of this project is the diffusion to the industry so that it know the new technologies and that they can finish them entering in his productive processes to improve the quality and reduce his costs of production.