Hasco Ibérica Normalizados, S.L.U. - Other complementary equipment for moulding

Hasco K3500/...

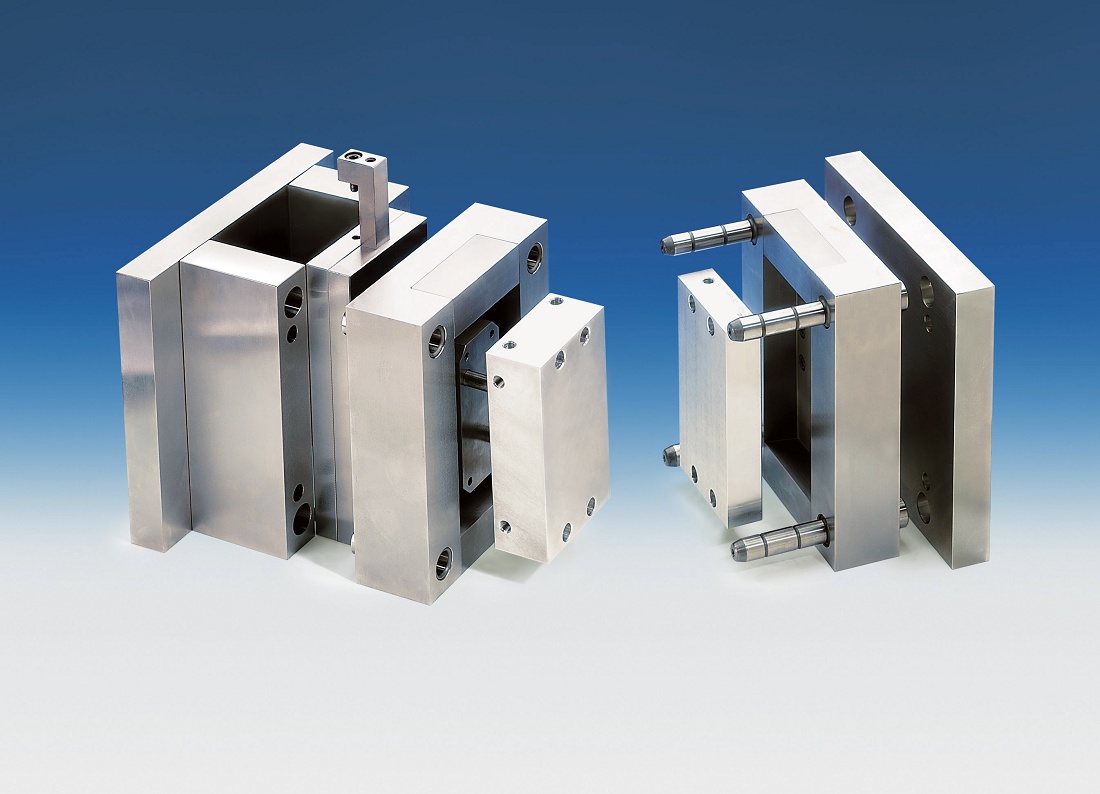

Quick-change mould system: for small production runs and prototypes

Hasco has developed the K 3500/... quick-change mould system to satisfy the demand for an inexpensive and practical solution for the production of samples, prototypes and small production runs. It consists of the actual mould frames available in the sizes 156 x 196 mm, 246 x 296 mm and 296 x 396 mm, and the corresponding mould inserts, K 3520/... and K 3501/... with an adapted ejector assembly.

The inserts can be supplied in the materials 1.2767 and 3.4365 to match the respective mould plate size. The bolster plates which hold the inserts are accurately made from prehardened tool steel 1.2312 and 1.2085. The inserts, which can be screwed from the parting plane, can be combined in different thicknesses either flush with - or projecting beyond - the parting plane and can thus be easily adapted to the core and cavity contours.

All inserts are delivered with machining allowance. By using well-tried modular principles we have deliberately ensured that the guide systems and the plate dimensions can be combined with Z and K standards of the same size. Both the inserts and the cavity plates have integrated cooling channels with connecting threads and hence provide a well-dimensioned cooling circuit in the two mould halves.

The cooling feed and return junctions are sealed with matching O-rings

Z 98/.... The mould inserts and ejection system can quickly and easily be installed into the mould. The moveable-side bolster plate has a cut-out for the ejector assembly, which is connected to the mould insert by adjusting screws, and is latched to the standard ejection unit, which is guided on four pillars. The connection between the K 3501/...mould insert and the K 3500/...

quick-change mould is made by a locking screw. Through minimum

setting-up times, downtimes are reduced.

All the necessary components are manufactured with the utmost precision and are available as part of HASCO's worldwide service as HASCO standard mould units.

Hasco's K3500/... quick-change mould system has been providing outstanding results for 11 years now, reducing throughput times and cutting costs. Because of its modular structure, it is the first choice for the economical production of small series and prototypes.

The inserts can be supplied in the materials 1.2767 and 3.4365 to match the respective mould plate size. The bolster plates which hold the inserts are accurately made from prehardened tool steel 1.2312 and 1.2085. The inserts, which can be screwed from the parting plane, can be combined in different thicknesses either flush with - or projecting beyond - the parting plane and can thus be easily adapted to the core and cavity contours.

All inserts are delivered with machining allowance. By using well-tried modular principles we have deliberately ensured that the guide systems and the plate dimensions can be combined with Z and K standards of the same size. Both the inserts and the cavity plates have integrated cooling channels with connecting threads and hence provide a well-dimensioned cooling circuit in the two mould halves.

The cooling feed and return junctions are sealed with matching O-rings

Z 98/.... The mould inserts and ejection system can quickly and easily be installed into the mould. The moveable-side bolster plate has a cut-out for the ejector assembly, which is connected to the mould insert by adjusting screws, and is latched to the standard ejection unit, which is guided on four pillars. The connection between the K 3501/...mould insert and the K 3500/...

quick-change mould is made by a locking screw. Through minimum

setting-up times, downtimes are reduced.

All the necessary components are manufactured with the utmost precision and are available as part of HASCO's worldwide service as HASCO standard mould units.

Hasco's K3500/... quick-change mould system has been providing outstanding results for 11 years now, reducing throughput times and cutting costs. Because of its modular structure, it is the first choice for the economical production of small series and prototypes.