Imvolca, S.L. - Extrusion lines

Comac

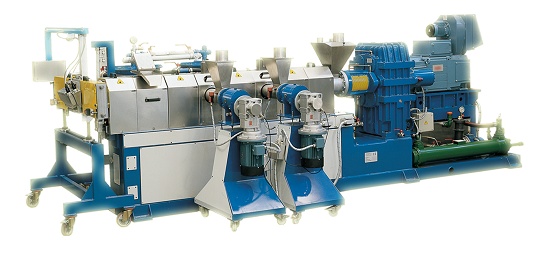

Lines for the production of lastras of PP: with fibre of long glass in coil

Comac, company commercialised by Imvolca, has lines for the production of lastras of PP loaded with fibre of long glass (‘roving') in coil fed directly in the extruder, to execute the called process D-LFT (‘direct long-fibre thermoplastic'). For this last have realised two lines with extruders of different sizes. In both lines, the extruder receives the PP and the possible masterbatch and/or additives in the main mouth through a system of dosage gravimétrica with loss of weight, whereas the ‘roving' feeds in a special module of the cylinder of the extruder through systems with guides, sensors and cabezal of introduction. The husillos of the extruder, of special profile, allow a regular incorporation of the filaments of glass, his segmentation controlled and the intimate mix of the fibres in the polymeric matrix.

The compound of PP plastificado that contains the necessary percentage of fibres feeds continuously in a cabezal flat that produces lastras cut transversalmente and lists for the continuous feeding for the successive operations. The concentration of glass in the compound generally configures between the 20 and 40% and in the lastra produced (that characteristic sample of good isotropy) the average of the length of the fibres of glass varies between 20 and 30 mm (can modify , inside some limits, taking part in the parameters of process and in the profile of the screws).

The compound of PP plastificado that contains the necessary percentage of fibres feeds continuously in a cabezal flat that produces lastras cut transversalmente and lists for the continuous feeding for the successive operations. The concentration of glass in the compound generally configures between the 20 and 40% and in the lastra produced (that characteristic sample of good isotropy) the average of the length of the fibres of glass varies between 20 and 30 mm (can modify , inside some limits, taking part in the parameters of process and in the profile of the screws).