Hasco Ibérica Normalizados, S.L.U. - Other complementary equipment for moulding

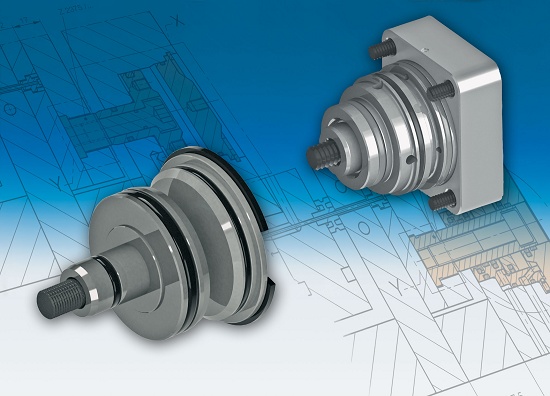

Hasco Z2371 / Z2380

Cylinders: for optimum control of mould plate assemblies

Multi-cavity hot runner systems are being built into smaller spaces, with tighter cavity to cavity distances. With needle valve gated systems, the plunger surface area is frequently not large enough for the necessary forces to close the needles. For this reason, new service-friendly cylinders for operating larger mould plate assemblies have now been developed. They are operated either pneumatically or hydraulically.

With the pneumatic drive Z2371/… only a plunger provided with Viton sealing rings is inserted into the appropriate hole of the platen. The screw connection with the mould plate assembly is then carried out centrally via the plunger. This means that, for servicing, the plunger can remain in the platen if the mould plate assembly has to be loosened. A cover provided with a locking ring seals off the system on the machine side.

The simple pocket machining geometry can also be carried out economically.

With the hydraulic variant Z2380/… the plunger has been additionally provided with a specially manufactured housing. The inner surface is designed specifically to meet the demands of an hydraulic seal.

This ensures a high level of impermeability.

As with the pneumatic version, the mould plate assembly is screwed through the plunger, which means that the hydraulic system remains closed and the user's environment is not contaminated with hydraulic oil.

The cutting geometry required for the platen has also been kept very simple to avoid unnecessary costs. The positioning of the feed holes has been designed so as to avoid any damage to the sealing rings during assembly.

With the pneumatic drive Z2371/… only a plunger provided with Viton sealing rings is inserted into the appropriate hole of the platen. The screw connection with the mould plate assembly is then carried out centrally via the plunger. This means that, for servicing, the plunger can remain in the platen if the mould plate assembly has to be loosened. A cover provided with a locking ring seals off the system on the machine side.

The simple pocket machining geometry can also be carried out economically.

With the hydraulic variant Z2380/… the plunger has been additionally provided with a specially manufactured housing. The inner surface is designed specifically to meet the demands of an hydraulic seal.

This ensures a high level of impermeability.

As with the pneumatic version, the mould plate assembly is screwed through the plunger, which means that the hydraulic system remains closed and the user's environment is not contaminated with hydraulic oil.

The cutting geometry required for the platen has also been kept very simple to avoid unnecessary costs. The positioning of the feed holes has been designed so as to avoid any damage to the sealing rings during assembly.