OpenSafety: A safe and independent protocol of the bus

Are beings of habits: still there are designers of systems of industrial automation anchored to the typical cableados dependent of the technology of control and the respective proprietary buses, many times, by comfort.

In the last years the systems of hygiene have caused a radical revolution in the transfer of signal of hygiene through bus of field, mainly through networks based in Ethernet, such as Powerlink. The advantages on the traditional systems are clear: the elimination of the majority of the cableado reduces significantly the costs and deletes a remarkable source of errors. Besides, in the systems of hygiene that use direct communication without happening through the controller, can fulfil with the rule of hygiene required reaching movements of greater speed, what means an increase of the productivity. Finally, but no less important, the integration of controllers and motors, as in the case of B&R SafeMC, shortens the distance of braked and allows distances of lower hygiene, by what is possible to build machines smaller and more economic.

Like result is easy to understand why all the manufacturers of technology of control and automation bet by the hygiene through Industrial Ethernet. “Only there is a way”, says Stefan Schönegger, director of the unit of business of B&R Open Automation, whose work is to do the technologies of B&R the easiest possible to use it with other manufacturers of systems and integradores. “With an alone exception, all these systems only can work together with the hardware of control or system of network of the respective manufacturers. This has to partly to technical reasons, but also to other unnecessary factors such as the politics of monopoly promoted by the market”. This can cause headaches for the manufacturers of machinery, since no always can choose which controllers use in his products, but often they have to follow the demands of his customers. This puts of relief the only real advantage of the systems cableados: once installed and certified, the solution keeps on being the same, independently of the controller that uses .

Interoperability thanks to the basic channel

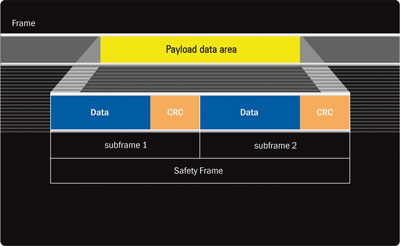

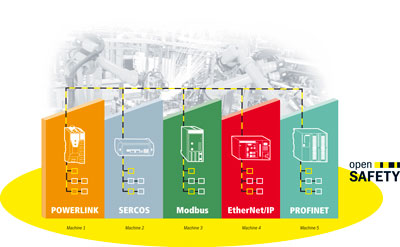

“A system of hygiene based in a bus does not offer this independence, whose price is too high for his others advantages”, affirms Stefan Schönegger with confidence. “One of the main aims of development of openSafety was not engaging the autonomy of the system of hygiene from the bus of the system”. The solution found in the principle of the basic channel, that allows the safe transfer of data independently of the protocol of communication used and allows that it was used in any bus of field.

This benefits no only to the manufacturers of machinery. The manufacturers of devices also obtain an advantage with a shorter time of launching to the market, since they only have to go through the development and certification an alone time. Besides, a uniform solution also requires fewer special knowledges and diminish logistical costs associated to the utilisation of different products and variations.

Georg Plasberg, boss of the division of Development of the Systems of Industrial hygiene and member of the managerial team of Sick AG, important German manufacturer of sensors, agrees: “In a lot of electronic applications, the interoperability of different systems has turned into practically a requirement. Although we go to be followed to integrate all the range of proprietary solutions in our products, think that only those that can surpass the limitations of the network using standard opened of communication will succeed on a long-term basis in industrial applications. Of course, we encourage us for this opening level further of the level of specification and until the level of interface of the systems of engineering”.

Profits for the manufacturers of devices and machinery

Like director manager of the exporting company to world-wide level Trumpf Maschinen Austria Ges. mbH & Co. KG, Alfred Hutterer knows the disadvantages that derive of the fault of interoperability in the majority of systems of hygiene. “This fault of interoperability between different systems no only is expensive, but it also increases the time of launching to the market and prevents a reasonable politics of shopping allowing have other alternatives of supply” said recently in a celebrated debate by a magazine of businesses of Austria in relation to the state of the technology. And it added: “The different schools of thought promote his individual technologies and do that it was difficult for the manufacturers of devices of field the development hardware that was compatible with the different networks”.

Manufacturers of machinery like Trumpf also benefit of the standard range openSafety, with fewer articles in comparison with the proprietary solutions and the capacity to use alternative providers when it was necessary. “This is not a factor of lower importance, since the availability always plays an important paper in the decision of the sales and the continuous satisfaction of the customer”, admits Stefan Schönegger. “The subject of the specific knowledges also goes in at stake for the manufacturers of machinery, since with openSafety, the technicians only need to be formed in an alone technology”.

Profits for the plants of production

In addition to the advantages of costs that the manufacturers of devices are able to transmit to the manufacturers of machinery and his customers, the companies of production and the owners of machines also can benefit directly of openSafety. The homogeneity of products and a wide application and opened also limit the expenses in courses of learning of technicians and the costs for the acquisition of spare pieces. “Still more, it appears an entirely new possibility”, says Stefan Schönegger. “Thanks to the independence of openSafety of the bus of the system, is possible to endow of efficient way to whole groups of different machines, robots and equipment of manipulation, with a system shared of hygiene, creating like this new profits for the productivity, that could not attain in the past with the conventional technologies”.