Vortex, a solution for difficult threads

The process of threading by Vortex has been always with machines designed for this purpose, requiring a large and costly installation.

Madaula are working in porta-herramientas designed to be mounted on motorized turret (lathes, Star, Citizen, Okuma, Mori Seiki, Mazak, Miyano, etc.) while preserving their ability to multitask.

Areas of application

Also applies to parts for dental implants, screws of bones for surgery, screws for hips, for maxillofacial surgery... even screws of lower diameter 1 mm can be tapped.

When comes to machined threads in difficult materials (stainless steel, titanium, temperate materials to 65 Hrc, etc.), few processes are so fast and efficient as the threaded by whirlwind.

While the process is not new, its popularity goes spreading capacity for coupling devices of vortex in CNC lathes and precision turned parts, still a solution really cheap and alternative investment on unique machines of threaded by whirlwind.

Advantages

- Threading without turning prior.

- You can be any kind of special profile.

- Without distortion on the piece, due to low shear forces.

- High-quality threads. Without inflections in the pieces.

- Very small shavings, without problems of shavings.

- Without burrs.

- Long life of the tools.

- Possibility of up to 40 reafilados before replacing it.

- Little effort to court. Little solicitation of the machine.

- Low power required.

- Thread "whole", no way out of thread.

- Implementation in a single pass.

- High practical rotation, that no real machine.

- Less downtime due to the long life of the tools.

Application machinery

Types of threads that can be obtained

- thread thumbnail

- thread extra long

- variable pitch thread

- conical thread

- threads of multiple entries

- deep profile threads

- "buttress" (deep support of Helix)

- visinfines

Principle of operation

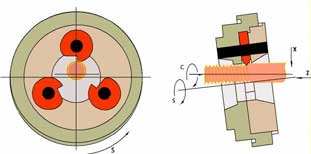

The Vortex is essentially a threaded process whereby the porta-herramientas head rotates the piece. The porta-herramientas is equipped with multiple teeth in court for the carving of the thread as "orbits" around the piece.

As shown in the drawing, the head has three blades that contact with the piece in movement, generating the thread into a single past and generally without turning prior. The cutting depth is around 2.3 mm maximum.

The piece revolves about 10 RPM, while the head porta-cuchillas does to 2400 RPM aprox. With the 3 tools by contacting the piece hundreds of times at every turn, the Court effort is minimal and finish quality is maximum.

The blades have to adjust to the angle of the propeller of the thread. This is easily done by means of an ingenious device. Also, the angle provides free space for turning the blades.

Shape of the blades

Comparative

| Piece: | Bone surgery of taper screw | ||||||||

| Geometry |

| ||||||||

| Machine tools: | Citizen M12 | ||||||||

| Material: | Steel inoxidable316 L |

Results

No Vortex | With vortex | |

| Spindle speed | 1,000 rpm | 10 rpm |

| Speed of the Vortex | n/a | 2,400 rpm |

| Depth of cut | 1.5 mm | 1.5 mm |

| Number of passes | 63 | 1 |

| Cycle time | 9 min 30 sec | 4 min 15 s |

Advantages of the whirlwind Madaula

They incorporate the latest technological advantages, fruit of a receptive attitude to the demands of customers, designed to facilitate further implementation to point and to ensure a consistent quality in threads.

No less important is the economic aspect, as the whirlwind heads are offered at prices never seen so far, increasing its attractiveness.