The car wears gala

Therefore, it is not surprising to see a rapid growth path in the replacement of such materials.

Plastics producers know that the development of new products only have value if they are adapted to the needs of the industry and customers, while they offer solutions to those needs. It is therefore very common collaboration with the automotive industry itself, since they are common knowledge for application in highly specialized areas, among which include segments of body or train engine, external, interior, chassis, electrical and electronic thermal management. A good example is the PC of the Mercedes Benz class Sportcoupé panel. Many drivers have struck an obstacle located on the ground when they were driving back down because they had not seen him. Users of this model of Mercedes won't they happen this thanks to the transparent panelling with PC Makrolon from Bayer. It is located on the top of the casket that blanket the tuition and expands the field of vision to the rear. Complete the proper rear Moon and extends almost to full-width of the rear door. The panel was very long and complex geometry and could not take place in glass, so it turned to the polycarbonate.

In another order of things, good management of the life cycle is based on the monitoring of applications during whole life cycle curve. Thanks to the management of the applications during all their life cycles, from a first embryonic stage through his appearance in the market and upgrading, to his initial replacement and decline, creates value for customers through innovation to adapt to new trends and industry standards, and gains in productivity to improve materials and increase the performance of the processing.

Other examples

Wheel covers have been produced are at nylon for years. This application is beginning to replace their usual material for polyolefins. It's a typical mature application. However, the industry of the automotive industry as a whole, from those responsible for molding manufacturers of vehicles, still want take advantage of this application through improvements in productivity. DuPont Engineering Polymers has proposed a solution which is to develop qualities of reinforced resin Minlon of lower cost, allowing to reduce the thickness of the walls of the covers of wheels, and therefore also its weight significantlyas well as offering a savings in production costs.

On the other hand, there is a demand increase in elements of comfort in the car, which in turn require more engines and electric actuators. The increasing demand of electrical devices for the regulation of the seating is a good example of this trend. To replace the metal with resin of Delrin acetal in such devices, manufacturers benefit from a reduction in weight and savings in production costs; on the other hand, this material allows the installation of the power seats in utility regulation systems and medium-sized vehicles, in addition to luxury car.

Sometimes, it is possible to add substantial value due to the updating of moulding processes. For these engines and electric actuators, the exterior moulding of the accommodation of these boards made in Delrin Hytrel thermoplastic polyester elastomer meant an immediate savings in costs, in terms of greater hardness and resistance to wear and fatigue of the component.

Cycle durations can also be reduced to shaping bolts for cars using the new nylon Zytel ST Advantage, rather than the standard Zytel resin resin. This material has less filling pressure and a lowest temperature of smelting, features, along with the reduced duration of the cycles of Zytel ST Advantage, resulting in significant savings in the costs of moulding.

Interest always on the rise of the automotive industry to reduce NVH (noise, vibration and mechanical resistance) problems has been one of the main factors that have prompted the development of resonators for increased performance. However, the appearance of the engines supercharged with higher temperatures under the bonnet implies the need to use more sophisticated resins in this type of application. DuPont Engineering Polymers to the automotive industry offers a solution to both problems through a specially developed quality of polyamide high performance Zytel HTN resonators of car that supports high temperatures up 160 ° c for turbocharged engines. The value in this case is achieved through a simple, cost-effective solution for two obvious needs of the industry. The result is both innovative and exciting: a soldier resonator of Zytel HTN.

The replacement of metal components is one of the main objectives of DuPont Engineering Polymers market in relation to the development of new applications. The accommodation of the sensor and the thermostat is a good example of the replacement of the metal with technical polymers in innovative ways.

The use of technical polymers in these applications contribute to the substantial reduction of costs through the integration of the components in the design, which implies the subsequent reduction in the number of pieces (and Assembly costs) and lower weight. Recently, the polyamide high performance Zytel HTN of DuPont has been selected to replace a more expensive material in the manufacture of the thermostat housing; the result was a simple production and an improvement in physical properties.

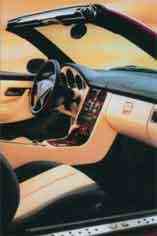

No less important is the aesthetics of the car. The new Mercedes SLK, a two-seat very athletic 'look' is regarded as a gift for the view. In design they have had an important role, for example, the front and rear bumpers and side trim of the mouths of entry. In the three works we have Bayflex 180 GR, polyurethane that is transformed by RRIM (reinforced reaction injection moulding) of thin-walled. Components PUR are injected into the mold with a fraction of short fibres. You get parts of thin wall, light but rigid while the torsion and stable dimensions.

The hands of this model are also very attractive. They are made from the Durethan PA which provides great stability to the temperature and chemical resistance, for example the salt spread out to melt ice and snow.

A blend of PC and ABS, the Bayblend is used in the shells of the mirrors, manufactured in Reitter & Schefenacker. It has been chosen by their mechanical properties, the thin wall thicknesses that permit and its good aptitude for painting. This same material is also involved in many visible pieces sporty and luxurious dashboard inside. Intense heating, for example in direct sunlight, causes minimal deformation, so that separation between the parts are not appreciated.

A retardant to seats

Plexiglas in the car

In addition to the already known of the masses of moulding Plexiglas applications these products are used increasingly in light management systems and in non-transparent parts for automobiles. As a driver of light in navigation systems, this material is used for its high purity and transparency, even in complex and highly branched forms. As an example of Plexiglas injection-molded body parts include the lining of the amounts in the Mini, the spoiler of the MCC Smart and the cover of the new Opel Astra outside rearview mirror. The light weight, high resistance to scratching, excellent resistance to weathering and colour stability as well as its easy workability are the determining factors for the increasingly greater use of these masses of moulding in the automotive manufacturing.

In addition, with the PFM system, the automotive industry also has a procedure that can be manufactured in parts of body in a single step of work: thanks to the extrusion multilayer sheets with these masses of moulding as color and final layer and subsequent injection layer obtained parts of body of high quality to manufacture lightweight, fuel-efficient cars.

Pagani in Modena/Italy made one of the fastest vehicles on the road: the Zonda, a sports of pure-bred with 7 litres and 550 horsepower engine. Rigid cellular plastics of polimetacrilimida Rohacell (Röhm Plexiglas of Degussa AG) as a material for manufacturing is used in the structure of the soil.

The structure of the soil of the Zonda, which supports a large weight, is manufactured as a single piece structure in surface layers of carbon fibre sandwich. The focus of the design was the reduction of the weight of the structure, maintaining at the same time an optimal behaviour in the event of collision. For this reason Pagani decided to use Rohacell as core material for the structure of the soil.

Under the hood

An interesting example is the case for a valve to the Ford Sigma. After stepping on the accelerator pedal, this piece regulates the adequate amount which must reach the engine. Taking advantage of the Fortron PPS 1140 L4 British manufacturer Visteon is producing this piece which has managed to reduce the weight and cost, as well as Assembly time.

The growing number of cars with Diesel engine and the tendency to temperatures high under the bonnet also require much materials. BMW incorporates a new device for the supply of fuel based on the POM Hostaform C 13031 XF 50/5339 in their engines. Its size is approximately 300 mm x 120 mm, with a weight of 350 g, is located in the tank and regulates the supply of fuel.