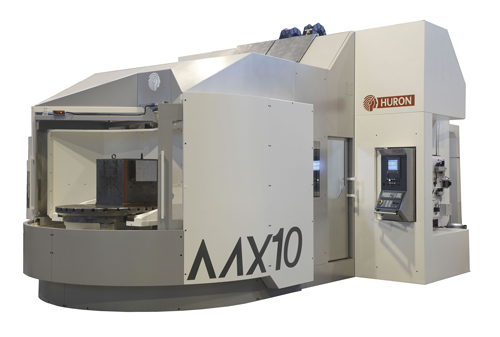

Centres of milling of the series MX of Huron: power, speed and precision

11 May 2012

The structure incorporates a column of trip manufactured in smelting with some exceptional characteristic mechanics that increase the rigidity of the machines and cushion the vibrations originated by the strengths of cut in the hardest materials. The rigidity, precision and geometrical stability see reinforced thanks to the points of anchorage in the floor.

Available in different sizes, the series MX offers machines ‘everything in one', entirely automated and compact that reduce the times of production at the same time that optimise the investments.

The concept modulate of MX 8 to MX 12 for travel of 1.000 x 1.600 x 900 millimetres to 1.200 x 1.600 x 1.000 millimetres and pieces of work with a weight of between 2.000 and 4.000 kilos, allows to choose exactly the machine that adjusts to the requirements of each application: milling or turning/milling, table giratoria or version paletizada, with probes, refrigerante, etc.

The table giratoria of the centres of milling multifuncionales of the series MX is instrumented with a pair engine. So much the pair of high twist like the rigidity of the design offer high power in the desbaste. In the version for turning/milling, the husillo blocks using an attachment Hirth. The table can turn until 500 rpm and thanks to his design, achieve some speeds of acceleration very high.

The pair engine is mounted in a plane to 45°, what allows a movement of -45° to +180°. Thanks to the husillo of high performance (pair, power, speed), is possible to withdraw the shaving to big speed, in addition to achieving an enormous precision and quality of the finishing in outlines and profiles. As it monitors the vibration during the mechanised, can work with total hygiene in the components of the machine and the tools.

There is available several options of cabezal, depending of the type of mechanised for which go to use.

The cabezal mechanical has been especially designed for the mechanised of hard materials like the titanium, Inconel, etc. Places in a plane to 45°, is instrumented with a husillo of high pair (6.000 rpm, 28 kW, 1.350 Nm) and is adapted so much for works of milling as of turning. It allows a turning in big desbaste with a fast speed of extraction equipment equipment of shaving. The cambiador of tools specifically designed allows to load tools with a diameter of 250 millimetres, a length of 250 and a weight of 25 kilos, respecting the properties of the husillo.

The cabezal of fork uses only for the milling and characterises especially by his capacity to reach negative angles. His rotatory axis, the B, displaces in angles of +10° to -110°, is parallel to the axis And, and allows to the husillo oscillate in a horizontal axis. The pair engine is connected directly to the pieces giratorias, guaranteeing a movement without angular game and a positioning of high precision. The cabezal is instrumented with a husillo able to reach until 8.000 rpm (86 kW / 235 Nm).

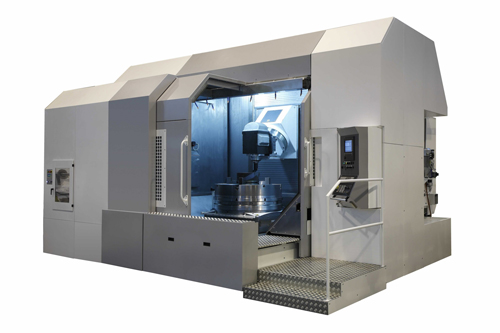

Thanks to that the two stations of work have of paletizador, increases the productivity, achieving load and download the piece of work in a record time. The paletizador rotatory is mounted in the leading part of the machine. The device of circular protection allows to decouple the palé from up, what offers ergonomics and facilitates the process of load/downloads.

With an especially innovative ergonomics, the series MX guarantees a level of productivity very high, in addition to the maximum hygiene for the operarios. The machines incorporate a standard warehouse for 48 tools installed out of the zone of work. Likewise, they have of a complete system of protection that guarantees the total hygiene for the user, so much in the zone of mechanised as in the surroundings. Opening the door can access easily to the table and to the piece of work, and the version with paletizador reduces to the minimum the time of inactividad during the load/downloads of the pieces.