DMG Chooses the accionamientos Redex to guarantee a mechanised of maximum precision

2 May 2012

The manufacture of big pieces like moulds or systems of tooling for car body parts of trucks requires the highest provision and precision in the mechanised. The requirements of mechanised for the carcasas of marine motors diesel are equally very strict. The pieces to mechanise weigh several tonnes and, although they are used to to have several metres of length, each micra is crucial.

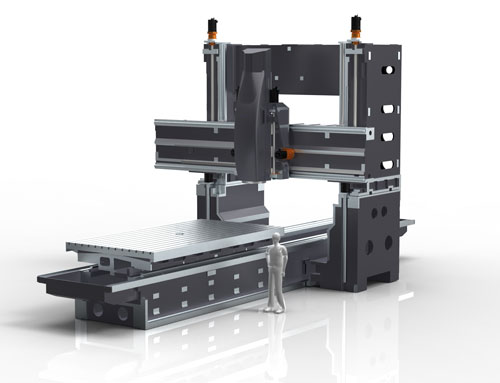

Mechanised precise of heavy components

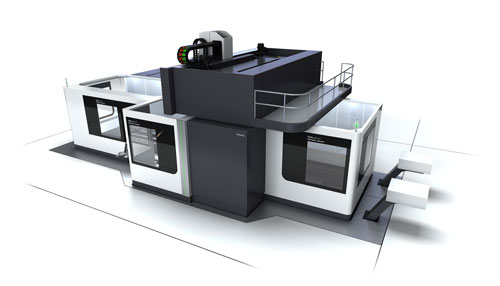

With this aim, DMG has developed the milling machines of portico of the series DMU P. The biggest model of the series, DMU 600P, has been conceived especially to realise operations of milling and turning of high precision in dimensions of piece XXL, being the maximum travel of 6.000 x 4.200 x 1.500 millimetres (axles X/And/Z) and of until 2.000 millimetres in the axis W. The weight of the pieces in the rough can reach until 40 tonnes. To his time, the DMU 600P guarantees speed and maximum flexibility, since it treats of a machine designed for the turning and milling of 5 axles in an only tied of piece.

High precision in long travel

One of the greater challenges for the designers of DMG was to guarantee the highest precision of mechanised in travel so long. In this sense, the accionamientos linear play a predominant paper. Florian Garbarsky, director of project of DMG in Pfronten: “The accionamientos have to have game zero, with a precision that can keep during thousands of hours of service facing strengths elevated directly related with the 60 kW of power of the cabezal”. Like this, in upper trip to 6 metres reaches a precision until +/- 0,0075 millimetres, with accelerations that can arrive to the 3 m/s². Therefore, a maximum level of precision, rigidity and avoid thermal sensors dilatations are prerrequisitos to take into account to the hour to design the complete machine. With these conditions of length of trip and levels of precision, the technology of transmission of husillos to balls was desestimada for this machine.

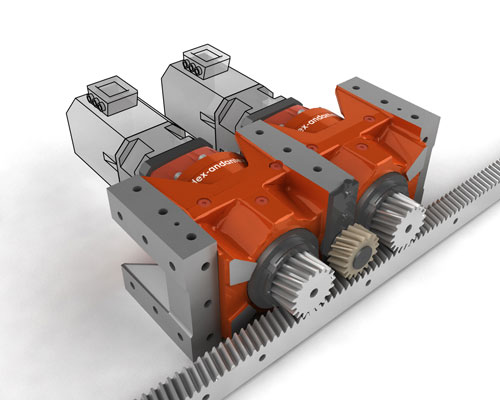

Accionamientos piñón-Zip

To guarantee the level of rigidity, the designers of DMG have selected with a lot of care some systems of accionamiento suitable. As it said Florian Garbarsky: “After a process of benchmarking exhaustive, have decanted us by the accionamientos piñón-zip without angular game of Redex”. Even in the axis C (rotary presses axis of the cabezal), an accionamiento of precision ‘TwinDrive' ensures a movement and a very precise positioning. Can appreciate also how the two husillos to vertical balls of the crossbar W are better synchronised thanks to two reductores servoplanetarios of Redex.

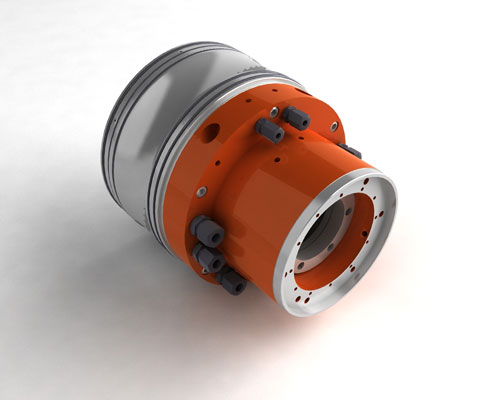

Accionamiento Of cabezal

To offer high productivity with a high pair to low speed has mounted a reductor of two speeds and refrigerado by water of the series RAM of Redex ‘on line' and integrated cheese cheese inside the ram (between the direct engine and the cabezal).

Axles X and And: accionamientos piñón-zip ‘Twin Drive' without angular game

According to the mechanical principle of the accionamientos piñón-zip, always exists some angular game that affects to the precision of the position of the same. However, this limit does not affect to the systems TwinDrive of Redex since the company offers the accionamientos piñón-zip with game ‘zero'. The basic principle consists in two reductores entirely synchronised that they use in parallel (engine + reductor planetary). One of the two servomotors acts like motriz and the another like brake, ensuring like this a precarga constant between the two piñones and the zip. This solution deletes entirely the game

angular and offers a movement and a positioning of maximum precision. And this same principle was the one who applied so much in the axis X of the DMU600P of 6.000 millimetres of length, in the axis And of 4.200 millimetres length, as well as in the rotary presses axis C of the cabezal.

For the axis X chose accionamientos DRP key in hand, formed by 2 reductores planetary lodged in a carcasa universal each one of them with his respective servomotor. In the axis And opted by the reductores planetary KRPX, incorporated to both sides of the car. Likewise, it used a DRP for the rotary presses axis of the cabezal (axis C). The CNC of the machine commissions of the synchronisation and of the precarga of the accionamientos TwinDrive of each one of these 3 axles mentioned.

The rigidity of the accionamiento contributes to obtain high dynamic and maximum precision

Although it is an indispensable requirement delete the angular game in the accionamientos by means of the precarga, this does not guarantee to reach the maximum precision required neither the best quality of the surfaces. For this is indispensable to have in addition to an optimum global rigidity, control the variations of temperature and have of the lower error of transmission, that is to say, exactly the characteristic intrinsic key to the reductores planetary of Redex. Like this, the accionamientos selected provide values extremely heights in linear rigidity and allows them guarantee an excellent precision of positioned, surfaces of mechanised and repetibilidad.

To guarantee this rigidity the reductores are instrumented with cojinetes of exit mounted in the system patented by Redex of axis-piñón of exit. In himself the group of cojinetes is composed by two threads of conical rollers precargados and extragrandes, installed the more near possible of the point of contact of load of the piñones. The accommodation of the reductor has been mechanised with extreme precision and has a design optimised to offer the maximum rigidity, independently of the steering of the load. His design no only ensures a rigidity to a very high pair, but it achieves the greater rigidity in all the other steerings, including in the flexión radial that, according to the exhaustive proofs carried out by Redex, is the causante of almost 60% of the total deformation in an accionamiento piñón-zip. Therefore, the flexión reduces considerably and the natural frequency of the axis improves a lot, allowing speeds of acceleration higher and move masses heavier, at the same time that they fulfil some requirements of precision more rigorous.

The advantages, in addition to technicians, are also economic

Finally, although no less important, DMG considers that the accionamientos of Redex win the game, no only from the technical point of view, but also from the economic. According to a study detailed of costs carried out by the manufacturer of machines, any another technical solution of similar precision can surpass the best TCO that offers Redex with his accionamientos piñón-zip for a trip of 6 metres in the axis X.

A versatile concept

The wide range of products of Redex destined to accionamientos of machines-tool allows that the engineers can choose freely between a boundless fan of possibilities, independently of the rigurosidad of the technical requirements. Redex Offers his concept of piñón-zip in different variants, for example, with precarga electrical or mechanical, of which DMG opted by the electrical synchronisation. On the other hand, these systems can include any one of the usual types of servomotor and different settings engine/reductor. For the axis C of the DMU 600P (rotary presses axis of the cabezal), DMG chose for example a DRP, a combination of two reductores servoplanetarios TwinDrive mounted jointly in a carcasa universal and that offers a true solution key in hand.

Pura mecatrónica under a same ceiling

Suffices with throwing a glimpse to the design of the DMU 600P to observe the capacity of Redex to offer a miscellaneous fan of possibilities of accionamientos of first class for machines-tool combined with his solution of piñón-zip ‘Twin Drive'. Like this for example, the reductor of two speeds, compact and of high performance of the series RAM that acciona the cabezal main of the machine forms part of the system of change of cabezales of the that has this machine, whose accionamiento carries out by means of an accionamiento ‘SingleDrive' with reductor servoplanetario SRP of Redex.

DMG Cost of the principle ‘all under the same roof' when choosing the same provider for all the axles motrices in his machines of high provision. And at all of this had been possible without the wide range of products of Redex that provides a technical solution for almost any requirement of the engineers. Finally, another fundamental appearance for DMG was the extensive support that received by part of Redex from the first phase of design until the put in final service. This is especially important especially when it uses for the first time an accionamiento piñón-zip. By means of multiple calculations and councils on optimisation and design, as well as through the assistance received for the installation of the accionamientos in the workshop, Redex achieved to offer a support of high value added regarding the use of accionamientos of machines-tools, contributing of form significante to the success of the machine. Success to world-wide level! As Florian Garbarsky finally added: “The machines of the series DMU P commercialise all over the world and are very sued for the mechanised precise, fast and economic of components of big size”.