This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

Hacer frente al centro de mecanizado crítico en fresado y tornoWith multiple configurations

Dealing with critical machining center in milling and torno

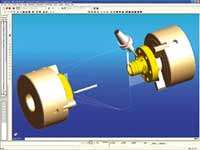

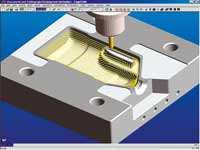

Pathtrace has been developing EdgeCAM with the conviction that the machining time is critical, which is accentuated when programming with multiple configurations machining centers. EdgeCAM 8 you will get a complete solution for machining centers complexes in strawberry and lathe (2 and 4 axis, axis (c), and and (b)). A system of effective CAM is absolutely vital to ensure the rapid return on your investment.

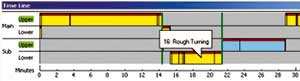

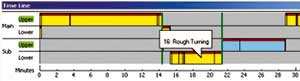

One of the strengths of EdgeCAM 8 is the ease of configuration, both the machine and the control over the parking lot of the spindle and the advance of the bar. To see the process of machining EdgeCAM 8 has the browser instructions and the "time line" of process. These tools display along with the synchronization of turrets, you will allow to organize the machining process to achieve the optimal use of the tool and minimum machining times.

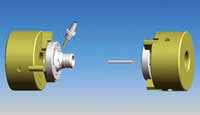

Sub-husillo, twin turrets and axis B

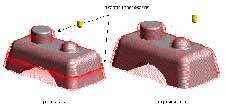

For programming with the sub-husillo EdgeCAM 8 automatically creates a duplicate of the piece. The pieces, in both spindles, are associated with each other, and at the same time with the original CAD design. This speeds up the configuration of the programming, and eliminates delays if a change takes place in the design.

With the simulator of EdgeCAM 8 you can visualize the simultaneous machining taking place in each spindle.

The great variety of cycles of milling and drilling that they were already available at EdgeCAM, as well as the automatic search of features now apply also to the b axis

Simplicity

EdgeCAM 8 includes an improved instructions browser, that allows to insert easily new machining instructions anywhere in the sequence. The new browser facilitates the work of programming by making it more comfortable and simple, especially for the programmer of turrets twin/sub-spindle. The option to define priorities, turrets tools can align and synchronize quickly, and also highlighted the spindle. All this leads to the optimization of the cycles that together with the time of machining information increase the degree of effectiveness.

The new window of the "time line", reports the sequence cycle times and refers to individual processes. The process can open by double-clicking allowing its Edition. Processes are color coded to help highlight the difference between the operations of lathe and strawberry in an environment of Strawberry/lathe.

This new tool helps the user giving him a clear picture of the machining sequence. Displays the status of each spindle and each turret, synchronization points can be set and highlights any conflict in the sequence. The color code adds a greater degree of clarity.

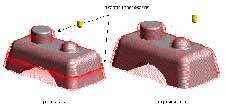

Automatic creation of tapas in features

With EdgeCAM Solid Machinist, improved the ability to automatically find machinable features in the piece, including the creation of "tapas" or surfaces at the top of each feature. These covers can be used as a simple method to override the characteristics of a process of machining.

Profiling finishing with intelligence

A new cycle of profiling finish offers greater control over the height of crest in finish machining by planes in Z.

Finish by planes in Z cycles are less efficient and are created with the same step down for the entire piece, without taking into account the crest heights required in each region. The region that requires a lower step dictates the passage for the entire piece. This creates a lengthening of unnecessary cycle time and makes the tool friction material rather than cut it with efficiency. With the new cycle of EdgeCAM, can create a unique trajectory for the piece, by intelligently controlling the passage through the crest height in each region.

A new option in the machining cycle 3-axis allows you to select an option to avoid turning the tool to reach the edge (hover over it) of a cashier or a male to the programmer. The advantages of this are related to many applications, resulting axes defined with greater precision in cavities, avoiding the need to create contours limit.

Simulation of machining

Improvements in the simulator of EdgeCAM 8 have been developed, has been a greater realism in the simulation of milling with moorings/obstacles static and dynamic in the same environment.

In the lathe simulation, you can see the simultaneous simulation in the main spindle and the sub-husillo, the car park of the spindle and the forward movement of bar getting a complete simulation of the dynamic movement.

More CAD integration

EdgeCAM 8 continuous his development with the transfer of configurations of SolidWorks, assemblings of Pro/And and the details of threaded of Autodesk Inventor. The link asociativo between EdgeCAM Solid Machinist and the main systems of CAD is fundamental for the continuous development of EdgeCAM.

EdgeCAM Solid Machinist Bears the following systems of CAD:

- Pro/Engineer 2001 and Wildfire

- Pro/Desktop 2001 and Pro/Desktop Expresses 2001

- SolidWorks 2004

- Solid Edge V14

- Autodesk Inventor R7

- EdgeCAM Part Modeler version 2.11

- Parasolid version 15.00.137

More information: www.edgecam.com

Related Companies or Entities

Dassault Systèmes España, S.L. - SolidWorks