Machine-special tool of big dimensions for the international market

CMI aeronautical sector component manufacturing sector component manufacturing sector component manufacturing, S.L. It created in 1993 in Seville, devoting to the aeronautical sector component manufacturing sector component manufacturing maintenance, until in 1997 in front of an increasing demand of manufacture and maintenance of the machine-tool, and taking advantage of his wide knowledges of the technology DYE and of the sector during but of 60 years, decided to move to his current location in the valley of the Duranguesado (Biscay), to cover all the fields to which at present devotes . Between them it stands out the manufacture of machine-tool (milling machines bridge, vertical lathes, etc.); the retrofitting (rehabilitation and modernisation of ancient machinery); maintenance; and mechanised of big dimensions (until 13.000 x 3.800 x 1.700 millimetres).

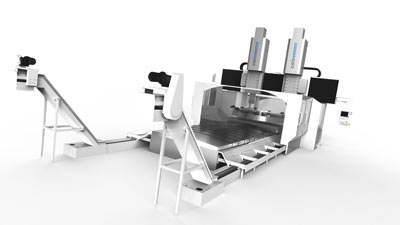

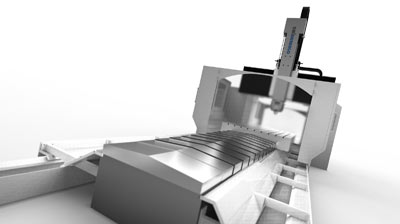

In his facet of manufacturer of machine-tool, CMIDurango develops equipment to measure according to the requests of his customers. They manufacture milling machines bridge and Gantry, lathes and taladros vertical of big dimensions. “It is machinery very special; we do not do standard machine. Everything is to measure, according to requests of the customer, and very focused to give solutions in the process of manufacture of each customer”, affirms Mikel Valiente. Examples of this activity are the milling machines Gantry for modelista, or others of 80 metres of length for the mechanised of prototypes and moulds for wind shovels. “Also one of the milling machines bigger and enormous for the aeronautical sector component manufacturing sector component manufacturing sector was developed and manufactured by us. This machine has 100 metres of long, has of 4 bridges, each bridge with 3 cabezales, and each cabezal with capacity of 5 axles”. Also the lathes and taladros vertical, especially the universal with applications of milling and travel in X, receives a big acceptance by part of the customers of CMIDurango. “Big and complex pieces can be finished entirely in a same process. Besides, the dish can have until 10 metres of diameter”.

To face a new design, “since each machine is custom-made, split of zero. The design realised in 3D aided by the tools of last generation. All design subjects to some calculations of resistance and durability to guarantee the highest levels of quality”, ensures the boss of Sales of the company.

The innovation also is to the agenda, as well as the continuous development of technologies and solutions that have to adapt increasingly to the segments of the most demanding sector. For Mikel Valiente, “beyond all doubt the segment of the aeronautical sector component manufacturing sector component manufacturing is turning into the most important, mainly by the constant innovations in the materials of the aeroplanes like the composites, fibre of carbon, aluminium and titanium. This without despising the one of the renewable energies, and especially also the one of the automotive sector, that to achieve vehicles with less consumption of fuels, and lighter, invests increasingly billions of euros in new materials that require new tools and processes of milling”.

In addition to manufacturing, the company offers the services of retrofitting, or reconstruction and modernisation of ancient machinery of big dimensions like taladros and vertical lathes and milling machines; repairs and maintenances of his machines (CMI and DYE) as well as of all type of machine-tool; and also a service of mechanised of big dimensions. The main demands of this service receive them of companies of machines-near tool: “we Can appoint to Ibarmia and Juaristi, that always have our service, quality and better term”.

Confidence in the controls Fagor

Although CMIDurango can realise set up with different marks of numerical controls, “mostly and by reasons of tradition always try to use the controls of Fagor”, affirms Sure, and like this justifies it: “Mainly by his simplicity of use that has turned into a comfort and guarantee, that to his time allows us reach the satisfaction of our customers in time records. The near technical service, with professionals highly qualified, fast answers and resolutivas, … all this causes that we use the controls Fagor in the cases where the final user want to”.

Between the main advantages that contribute these numerical controls to his machines, Sure enumerates the simplicity of use, easy programming, technical service, adaptability and modifications, innovation and reliability.

Especially, in the case of the division of retrofitting of the company of Durango, the CNC Fagor plays an important paper. “Our retrofitting are integral and comport usually that only it finish taking advantage of the metallic structure of the machine. All the cinematic, husillos, wired up, electronics equipment dealers equipment dealers etc., renew completely. It is normal that in a retrofitting integral place a new control, and here where the final user requires it, put Fagor. It does not fit doubt that to our customers try always show the advantages that obtain with a control Fagor”, ensures Mikel Valiente.

But by the special character of the machine-tool developed by CMIDurango, custom-made, “are always supeditado to the control chosen by the final user. All the controls in general adapt to all the machines. They are the reliability, easy handle and experience of the final user that does to decant by one or another control”. In this sense, is easier to work with a next company geographically, like Fagor, “a considerable advantage for us, but also our machines export to any part of the world, and is there where explains the geography”.

A bit of history…

Duñaiturria and Estancona, DYE, created in 1939 and in 1948 moved to the street Zeharmendienta, 2 of Durango (Biscay), current installations of CMI aeronautical sector component manufacturing sector component manufacturing sector component manufacturing. Like manufacturer of machine-tool developed in his first different years types of machines, as for example: boring mills, taladros of column, horizontal lathes, brushes bridge and broaching machines.

To his time, in the year 1948 José Estancona manufactured a car for his personal use since in that moment there were not trucks in Spain, and like this arose an idea that took form in the year 1951 creating two prototypes of car and a van to try his manufacture in series. But after several years to promote said contrives the project could not realise, because of the opposition of other no national marks that tried to enter in the national market, and finally the pressesures on the Administration achieved to veto the project.

Of this form, from the year 1956, DYE centred of full in the manufacture of machine-tool, developing his own technology DYE and specialising in machines of big dimensions, of the type milling machines bridge and vertical lathes.

CMI bet by the automation of Fagor

But the relation with Fagor comes of far. Specifically they work with the signature from does more than 12 years “and in numerous occasions have been the first in testing some element”, adds Mikel Valiente. A necessary cooperation if we take into account that the business of CMI does not base only in manufacturing machines seriadas but they realise a lot of prototypes, “by that need a good support ténico with regard to the electrical part of the machine”.

A service that Fagor offers them and that the manager of CMI defines like “ascendant and agile. In CMI think that Fagor Automation has a human team with big capacity, always are had to the new challenges that pose them. Besides, they are very agile resolving the daily problems, something that value enormously”.