Taladros Of refrigeration for the aeronautical sector

4 January 2012

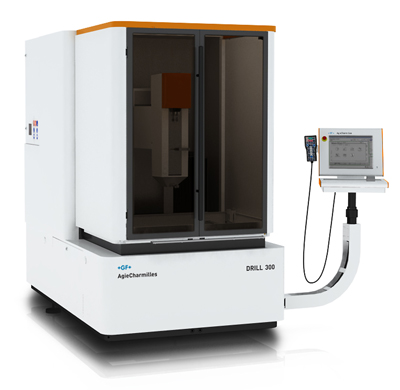

The Drill 300 has a compact and fixed table that allows a route of 600 x 400 millimetres (X x And) and 450 (optativamente 650) x 450 millimetres (Z x W). The generator and the unit of the dielectric have integrated in the machine and, besides, can purchase incidentally diverse options of axes and of axes of automation. In the development of the new Drill 300, the team of investigation and development of GF AgieCharmilles has centred in the true needs of the customer.

Powerful generator for an excellent performance

The Drill 300 is instrumented with the generator ISPG of GF AgieCharmilles, with a half current of 30 To maximum (optativamente 60To). The length of the impulse can reduce until a hundredth of nanosegundo. The form of the impulse of current improves to the maximum for taladrar. The generator ISPG by his part occupies to reduce the wear of the electrodes, obtaining a layer affected of less than 10 μm.

The generator ISPG of the Drill 300 offers the following strategies of control of processes.

- Recognition of the first spark: the generator recognises the position of the first spark and adapts to the surface of entrance of the piece to mechanise. This strategy protects the profile of the electrodes and preserves the quality of the taladro in the entrance; it treats of an appearance stood out in the applications of taladros of refrigeration.

- Compensation of the wear of the electrodes: the generator measures the real wear and knows in this way the position of the electrode. This strategy serves to avoid that the electrodes go out of the guide and to realise blind holes in depth more exact. The electrodes change automatically after the calculation of the rest of the electrode and the resources administer of agreement to the previously determined rules by the operario.

- Detection of the hole: the generator knows with precision when has realised the hole. This strategy guarantees the quality of the hole in the final finishing and protects the piece to be damaged, therefore they disappear the mechanised bad called ‘Back Hits'. Besides they reduce the times of mechanised.

High flexibility for the production

The Drill 300 has conceived for the realisation of perforaciones varied of diverse diameters in pieces to mechanise of different materials in production of masses. It offers a wide spectrum of destined technologies to different materials of electrode or of pieces to mechanise like Inconel, titanium, steel and carbide.

The routes are of 600 x 400 millimetres in the axis X and the axis And and of 450 (optativamente 650) x 450 millimetres in the axes Z and W. It can control equally a quantity of until eight axes (X, And, Z, W, cabezal abatible, To, B, C):

- Owing to the longest route in the axis Z can employ an electrode of 600 millimetres for a maximum of autonomy.

- With the cabezal abatible in ±45º the perforaciones that carry out in vertical concerning the levels X and And realise without effort.

- In the configuration of five axes the machine is appropriate for the perforaciones refrigeradas in plates of turbines and light sheets.

- With a table of positioning circulate can realise perforaciones had circularly.

The interface man-machine (HMI) of the Drill 300 makes possible so much a simple programming of the taladros individual on the one hand, like the powerful programming for several pieces and taladros, and this even with technologies and electrodes/guide distinct.

Diverse levels of automation

The stabilizer of electrodes is standard to end to reduce the automatic change of the electrodes and avoid the vibrations of the fine electrodes during the mechanised.

The Drill 300 can instrument with the cambiador automatic of electrodes and guides 16/4 or 50/8:

- 16/4: economic solution for standard applications.

- 50/8: solution of more prolonged autonomy and maximum productivity.

Is equally possible the connection with a carrier of pieces to mechanise and the system of management of workshop.

Control CNC comfortable and easy to use with powerful performance

The Drill 300 has of a control to distance with all the cycles of installation, axial movements for the orientation and a control of cambiador of movements of axes for the orientation, as well as a control of change of tool for the preparation of the electrodes/guide. The axes displace to a speed of until 4 m/min to end to save valuable time. The programming of the taladros individual is simple and intuitive for only holes: easy and fast. The preparation of the works serves for the programming of multipiezas, multiagujeros with different technologies and electrodes/guide different: easy and of powerful performance.

AC CAM DRILL matters data DXF/DWG/TXT/ISO to the machines of cut by erosion of GF AgieCharmilles and adapts the operations of taladro with what the operario with the interactive help can define the technological parameters, the sequence of taladro and the selection of one or several groups of holes.

The management of the electrodes/guide takes place of intelligent form by means of the determination of the type of cambiadores, the quantity, the length and the position of the electrodes. The guide selects automatically according to the electrodes selected.

Basic surface reduced

Thanks to the compact design of the Drill 300, in which so much the generator like the unit of the dielectric and the cambiador of electrodes find integrated in the machine, as well as to the fixed table, have achieved some reduced dimensions of the machine.

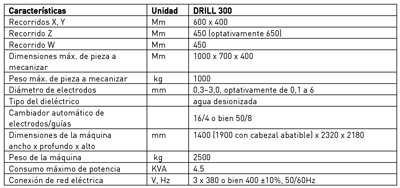

Main specifications of the Drill 300: