Measurement of strawberries of generation

14 October 2011

1- Measurement in the machine of toothed

In this case, the tool measures in the machine of toothed with pulsadores of measurement. Often this carries several hours, during which the costly machine of toothed can not produce any piece. This turns it into one of the machines of measurement more expensive of the world.

2- tactile Measurement out of the machine

The tactile machines of measurement by coordinates, conceived especially to measure toothed wheels finished, also use irremediablemente to measure the strawberries of generation. This sucede many times because it does not exist another possibility, but the advantage is that the measurement realises/realizes while the machine is working. At the same time it exists the disadvantage that the measurement realises/realizes by contact and that it needs long to attract the points of measurement until the programming. Between the criteria of assessment also find the high costs of acquisition and the specific training of the personnel. In the case of strawberries of generation instrumented with plates giratorias (from the size of module 6), the machines of tactile measurement present the supposed advantage that it also is possible measure the seats of the plates. However, a plate giratoria computed virtually involves the risk that in the original the plates giratorias are subject to tolerances and that, therefore, was not possible to ensure to 100% the result of the mechanisation/mechanization (without plates giratorias).

3- Measurement without contact with technology of processing of image

The industrial technician of processing of image presents the advantage, in front of the tactile measurement in tools of mechanisation/mechanization by start of shavings and therefore also in strawberries of generation, that the measurement carries out without contact. Besides, in all the field of looks of the camera, and therefore along all the projection of the shadow of the edge, is possible to attract in few seconds between cientos and thousands of points of measurement. Modern and powerful systems of processing of image are able to scan, calculate and value entirely even the real outline of tools in espiral with plates giratorias incorporated in position oblicua (like sucede in the case of the strawberries of generation instrumented with plates giratorias). This means no only time of measurement shorter and any danger to damage the edge or the pulsador, but especially a verification to the one hundred by one hundred of the tools in what to the result of the mechanisation/mechanization refers . At the same time, the big quantity of points of measurement allows to reduce considerably the imprecision of measurement.

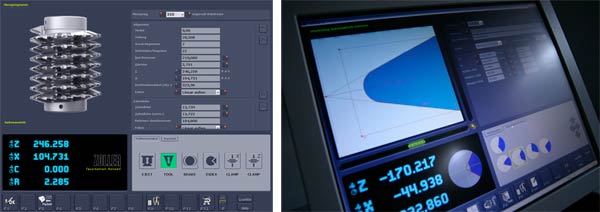

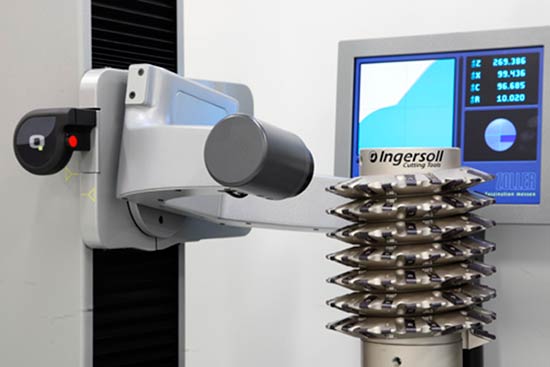

Zoller, like manufacturer of technology for the verification and measurement of tools, also has allocated a lot of resources to the subject of the strawberries of generation and in collaboration with Ingersoll, in Haiger, has developed an innovative concept for the comprobación of strawberries of generation in workshops that combines hardware and software. This concept bases in the optical support giratorio controlled by CNC ‘venturion 600 or 800' of Zoller (photo 1) and the software ‘pilot 3.0' with the dialogue of entrance of data fotorreal ‘Strawberry of generation' (photo 2). When entering the nominal parameters that extract of the drawing of the tool, the cost of programming reduces to the minimum. By means of the nominal data prefixed, the software ‘pilot 3.0' of Zoller (photo 2) generates automatically the program of measurement. The positioning and the measurement of each one of the points of measurement in the edges realises/realizes of form totally automatic and without the intervention of the user. To avoid the superposición or the distortion of the edges caused by the helicoidal step, the optical support of the system ‘venturion' of Zoller turns, if it is precise, of automatic form, controlled by CNC and ultraprecisa (photo 3).

Another advantage of this strategy of measurement affects to the catchment of the complete real outline of all the edges. This is especially important in the case of strawberries of generation instrumented with plates giratorias, since the outline in the piece of work comes given by varied and therefore different edges. Only the catchment of the outline of each one of the edges and his superposición splitting of all the edges until obtaining the complete outline allows to detect of a fast and reliable form possible errors of transition, tolerances of plates, errors of setting or transgressions of the tolerances in the seats of the plates.

With the team ‘venturion' of Zoller and the program of measurement for strawberries of generation Ingersoll, the user has of a system oriented to the practice to verify of complete form, fast and with precision micrométrica strawberries of generation before using them in the machine. On the contrary of what sucede in the majority of the machines of tactile measurement of this sector, does not leave to the election of the user what can measure with the machine of measurement. The system Zoller is designed to measure of the existent needs in the field of the strawberries of generation and besides can measure and verify tools of any type (escariadores, strawberries, cabezales portacuchillas, etc.), what at the same time supposes an important value added.

The result of this conjoint development of Ingersoll and Zoller puts of self-evident the advantage that supposes for the user a cooperation between partners.