The cooling in the transformation of plastics

The high temperatures of a process of transformation of plastics should be monitored, on the one hand to form the pieces moulded, extruded or sopladas, so that the molten material solidify and, on the other, to avoid mechanical machinery breakdown, because the aforementioned hydraulic circuit oil must remain in certain temperature margins. To do so both machines and moulds and rows, have internal circuits for the passage of fluids, the temperature of which must be controlled accurately. This task is possible with different types of machines, such as water coolers, thermos convectors, evaporative towers and Thermo regulators.

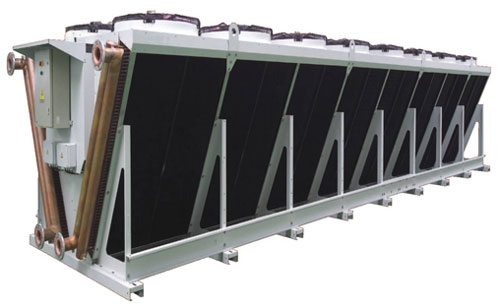

The main objective, cool, is being carried out in most cases by so-called refrigerators to closed-circuit. These teams, which meet the needs of the application can be of various sizes, powers and capabilities work making an indirect heat exchange between refrigerant fluid which will arrive in the machine (mainly water) and a gas which is cooled in an internal circuit. These teams equipped with one or more compressors (according to power required) circulated continuously a coolant gas valve expansion and evaporator, condenser, and in the process of compression and evaporation of gas which goes alternately from fluid to high pressure gas at low pressurecold, which refrigerará the process of cooling water is generated and released heat to the environment. There are refrigerators condensed air, where the gas condenser is a radiator which some fans make circular air at room temperature; or coolers condensed water, in which case there is a heat exchanger which transmits the heat generated by the gas to other coolant fluid (water) that will circulate to another remote computer that her wax cold at room temperature. In both cases we have a machine that provides cold water for cooling molds, rows, or machines. You can work to several degrees below zero if he is needed, for which there is to treat the water with glycol (antifreeze). These coolers have an electronic control panel, select where the temperature of the water that we wish to achieve. They tend to have an internal disposal of accumulation, and Recirculation pump, and teams are in the range of powers considered small and medium (up to 100,000 Kcal/h), monoblock, fully autonomous even some laptops, with wheels (normally up to 20,000 Kcal/h). The movement of the water is always in a closed circuit, there is no contact with the environment or other fluids.

"The power of cooling of these machines may be in k/cal/h or kW/h, which would be the k" cold generated every hour. The calculation of the power of cooling of a given application is determined by the type of process to cool and working temperatures, but usually used simplified formulas to make this calculation. For example, in a process of injection is determinant the type of material and its specific temperature, and the kg per hour of this material to be cool. You can use a simple formula: Q = P x K, where P is the hourly production and K the enthalpy or Kcal/kg time of each material (extracted from a table). In other words, to cool a conventional 100 kg/h of polypropylene plastic injection process (enthalpy = 150) have: 100 x 150 = 15,000 Kcal/h. Precisamos a refrigerator that we ensure, at least 15,000 freezing capacity Kcal/h. If we want to know what additional freezing capacity has to be our refrigerator to cool the hydraulic circuit of the machine for this process of transformation by injection or the process machines use this another simplified formula: Q = PM x 860 * x K. Where PM is the power in kW of the engines that move the hydraulic pump, 860 are the necessary Kcal/h for each kW of power and the utilization factor K, usually 0.5. If we had in this case 100 kW of power would give us: 100 x 860 x 0.5 = 43,000 Kcal/h.

Usually for the calculation of cooling power, distributors of the teams can advise at the user end of the power required in each case.

Determinants are also refrigerator equipment maximum ambient working temperature and the temperature of the cooling water, since these values are much more extreme, lower performance will have the team. For example a refrigerator whose manufacturer determines that the team only has a cooling capacity of 100,000 Kcal/h with the cooling water at 15 ° C in extreme working conditions from 35 ° C of ambient temperature and selected cooling water at 10 ° C and 25 ° C of ambient temperature will provide 74,000 Kcal/h. This point has to be taken into account and verify the freezing capacity of a team determined by a manufacturer, to which working temperatures gives and that real working temperatures is to work.

Evaporative towers and Thermo convectors

Other cooling equipment used in the plastics industry are evaporative towers. They do not have compressor or gas circuit and work by exchanging heat application from cooling water with air at ambient temperature. Due to the natural process of evaporation of the water tower works in open circuit and has direct contact with the environment, you can get water temperatures some degrees below the temperature of the air, but in extreme conditions, e.g. with temperature of 35 ° C, cooling water which we send machines or moulds will not drop 30 ° c. In addition, this water should be treated no evaporation there is risk of calcareous deposits, Legionella in environmental pollution; and in recent times the rigidity of environmental regulations, the cost of the treatment of water and periodic analysis should be made to appear on the market a type of alternative refrigeration system, convectors Thermo. Evaporative towers have as main advantage technical simplicity and affordable cost compared with refrigerators, and as the above mentioned disadvantages above with regard to the contact of the water environment and low accuracy in control of the temperature of the water in refrigeration, highly dependent on the ambient temperature.

The Thermo convectors are similar systems on the evaporative towers, but unlike these water circulates in a closed circuit, without contact with the environment. These are usually equipped with ventilators radiators and an electronic control which by varying the speed of these achieved a high precision control of temperature of cooling water. In the absence of evaporation, the minimum working temperature equals the ambient temperature, although atomization of water systems, so-called summer emergency, can achieve temperatures of the cooling water somewhat lower than the temperature, if the installation is well done.

Regulation of temperature

On processes that not only has cooling but maintain a specific temperature which in some cases can be high, we use the termorreguladores. These machines have an internal disposal, pump, heating, direct or indirect internal cooling circuit resistance and can work with diatérmico oil as fluid of high temperature or thermoregulation in the majority of cases with water, and can reach 95 ° c or up to 160 ° C if the water is pressurized. As in the case of all the teams previously mentioned exist of varying capacity and power, depending on the application and may, for example, heat quickly a mold to start a moulding process quickly, and once stable working temperaturethrough the liquid thermoregulatory heating or the cooling, maintaining that temperature constant.

Other teams that recently appeared on the market are teams combined portable cooling/for restraint or great power, able to deliver on the one hand warm water and cold water on the other, or water at two different temperatures, special applications.