Support necessary for an efficient exchange of automation components

on April 13, 2011

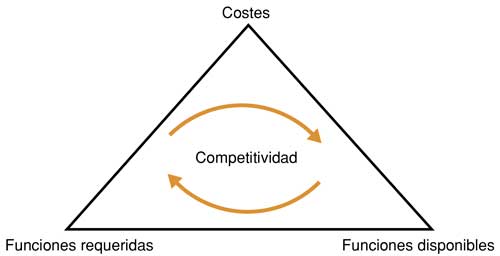

The model shown in Figure 1 illustrates the relationship between the costs of purchase, the requirements of the client for the functionality of certain techniques and available functionality from the provider.

Buyers are, of course, the objective of maintaining the start-up costs as low as possible. To make sure these low costs, estimates are made at a level of component, apply unit pricing. This method allows clear comparison between the manufacturers of automation and, therefore, encourages competition. To ensure compatibility, above, in addition to possible comparisons, it is vital the compatibility between the components.

Solutions to problems of compatibility between manufacturers

The ability to Exchange and compatibility, described above, also allows the user to avoid the use of specific features, sometimes closed solutions offered by the manufacturer of automation. Optimizing the solution of automation and providing this flexibility to exchange these conflicts become excellent competitive results.

Inevitably, in relation to this goal conflicts arise. In order to find a solution to these problems, it is necessary to determine if, in fact, they are part of the overall objectives. In doing so, defines a common goal of highest level, which is pursued by the manufacturer of the machine or system, and by B & R, as a true partner. This common goal is to establish a lasting competitive advantage over the competitors of the machine or system manufacturer. If the strategy of purchase and the process of decision making is derived from this objective, in the first place, the competitive advantages should be identified and evaluated.

Are initial costs the best indicator of the value of the investment?

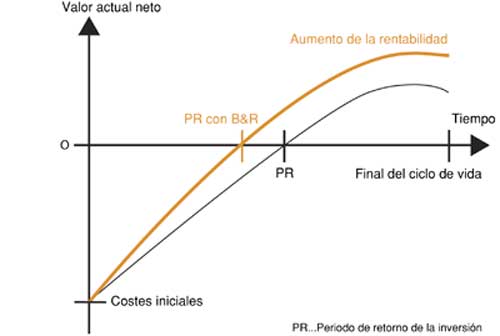

From the point of view of end-users, the most obvious method for achieving a competitive advantage is apparently to reduce initial costs. These often relate to the real value of the purchase of the machine or system. However, a machine not only operates on the day when it starts up and install. This will produce goods for a long period of time.

During this time the machine generates cash flow continued to the end customer through the sale of the produced items. As a result of this cash flow the start-up costs of the machine are paid within a specified period of time. Once these costs have been paid, the cash flow of goods sold is used to cover the fixed costs of the company.

Calculation of dynamic investment techniques are used to calculate the true value of the investment. These calculations consider also the passage of time, in addition to the initial costs and cash flow. The future cash flows should be devalued because of the capital which has already invested (Lechner et. Al., Einführung in die Allgemeine Betriebswirtschaftslehre, 23rd edition, 2006, Linde, Vienna, p. 315). These techniques must be applied before the investment opportunities for a transparent comparison.

Productivity as a competitive advantage

The calculation shows that investment is focused on minimizing initial costs if not achieve other objectives. A real competitive advantage is obtained through a short period of recovery, which lengthens the uptime of the machine and contributes to the benefit of the company. In addition, the devaluation of the future cash flows is reduced by reduced payback period. Figure 3 shows this relationship (Franke, Finanzwirtschaft des Unternehmens und Kapitalmarkt, 2003, page 189).

The slope of the curve of the net present value is determined by the productivity of the machine. The increase in productivity reduces the payback period. The effect is similar with low initial costs. However, if the lifetime is taken into account, it is a clear that productivity is more important than the initial costs, as long as maintaining an optimal price/performance ratio. As described previously, reducing the payback period is extended the time where the machine is productive and contributing to the benefit of the company.

Efficiency of productivity

Performance, production, and the time of inactivity of a machine, have a great impact on the productivity of a machine or system. In the past 15 years, the design of the Automation has become the dominant factor in productivity. Initially, this was mainly due to the characteristics of the modules of hardware (PLC, unit of servo, etc), but today it is the combination of hardware and software that makes the difference. For example, in the case of the drivers, this combination makes it possible to carry out movements of high accuracy and dynamics. At the same time, the system guarantees that the movements are energy-efficient, a rising value for current times.

A step ahead of the competition

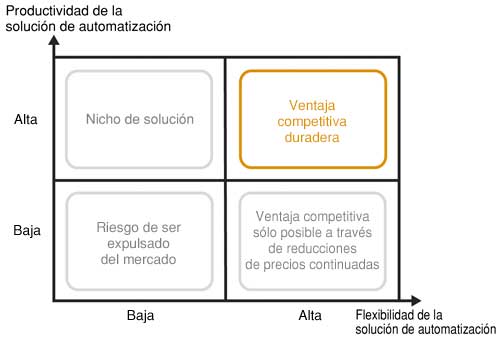

To stand out from the competition, the solution of automation in a machine or system have to be customized to meet the unique needs of the application. B & R specialists propose the best solution of automation and the client provides the necessary knowledge on the process technology. Long-term, attempt to find the best solution for automation of the machine is reached to provide an optimal ratio price/performance, while ensuring that the manufacturer of the machine is still a step ahead of the competition.

Competitors can copy eventually used in a machine mechanics and equipment used, but the combination of hardware and software, the solution of automation becomes a differential and lasting competitive advantage. As a provider of complete solutions, B & R also develops software components necessary to parameterize their hardware products. With Automation Studio, users have a single software tool for configuration, programming and diagnostics of all B & R teams. This system ensures that all hardware products are configured in a single way. A close relationship between the hardware and software offers results with a clear competitive advantage in the long term.

Figure 4 shows how the flexibility of the solution of automation, coupled with an increase of productivity, directly affects the machine and the competitiveness of the manufacturer. B & R has a wide range of effective solutions of hardware and software for any application.

The optimization is not a contradiction to established standards

Of standardization, as PLCopen organizations have recognized that when a standard is defined, only the lowest common denominator of all the companies involved can be specified exactly in the standard. If a manufacturer like B & R is limited to this standard or standard (for example, PLCopen MC), is not possible to add a lasting competitive advantage. On the other hand, these standards provide specific extensions of the manufacturer, to ensure compatibility and functionality.

For example, this allows the system Acoposmulti Act to its full potential and maximize the performance of the machine or system. Another example is the implementation of Powerlink. As the network protocol integrates seamlessly into any system B & R, axes and control of inputs/outputs are totally transparent to the user, allowing that the application is accurate and the speed of the network does not affect the standardised programming, according to IEC61131-3, Ansi-C.

Werner Paulin has been working for B & R since 1997 and has carried out activities in the Department of international applications. These activities include design of SW, programming and customer management. He has also played several years with B & R China, offering support for applications and actions in the sales department.

Since 2005, Paulin is responsible for ensuring that software products meet the needs of the user, specifically in engineering projects, for applications with drives in Automation Studio.