Interview with Modesto Porto, Vice President of Maquinser

With more than 35 years of history made by the founders of the company, his first experience with 5 axes, even before becoming Maquinser, dates back to 1975, when they installed a Cincinnati Milacron Gantry of 3 heads and 15 metres of x-axis in house Tablada. Since then it has rained much but the time has not diminished the desire to innovate, improve, and work closely with the client. Thus conveys it Modesto Porto, we cited in modern facilities that the company has in Granollers (Barcelona), taking advantage of the meeting of the Council.

Porto is clear that the history of certain companies of reference is linked to Maquinser since its inception as a provider of trust and shock technology. "With the implication in resources that it requires when a pioneer in the application of new technologies." I remember the first machine of high speed of truth, the installed in Consur in 1991: a FX5 Matsuura. "The productive difference of this machine revolutionized the world of aluminium machining".

Porto provides the point of view of the supplier for the aeronautics sector. According to him, "the companies tractors or Tier 1, either separately or by clusters, manage to capture contracts which, in turn, distributed by the industrial fabric trained, accredited and sufficiently productive means". Their customers. Companies constantly need of investment in high technology. "If you take a look back, seem ridiculous specifications and requirements of 20 years, but so aggressive market that we are moving is necessary to clean up production processes in order to compete even at the global level".

When you enter Maquinser in the aeronautical sector?

Maquinser was created in 1987 although the truth is that you people we compose the company have experience in the sector since 1975, and since its inception because we work with the aeronautical sector. In fact, the first machine that sold Maquinser, the first Matsuura, in 1987, was sold to Consur, our main customer for the aeronautics sector. It was a machine for the machining of aluminium. It is true that at the level of subcontractors, this sector was beginning, but a company like CASA (Construcciones Aeronáuticas, S.A.), created in the 20s of the last century, was and is the flagship of the Spanish aerospace industry.

Currently, what range of machines offers Maquinser for this sector within its extensive catalog of products?

3-4-5-Axis machines from very small to large parts dimensions, 20-30 meters. We mechanized any type of material: the traditional aluminum and titanium and the novel such as carbon fiber or the honeycomb.

We are talking about machinery requiring very specific specifications. What are the contributions of Maquinser in this sense?

Firstly, I believe that the key to success is the level of the product. The demand is very high by clients and we can shoulder. Then, at the human level, we have a highly arranged team, which is well aware of the sector, by the experience and the continuous training received. Thirdly, the philosophy of Maquinser: reliability, delivery to the client and responsibility for the projects.

In fact, it is a market that is constantly evolving. Manufacturers of machine tools follow this rhythm?

Yes, the truth is that you moving continuously. And happens, every time, with turnkey deliveries and very specific specifications, that the customers ask for special executions which is make modifications and include important features, as the case may be.

I know that in Maquinser engineering they already have cases of success in terms of turnkey implementations...

Yes, for example for the A400-M, the plane that is mounted in Seville. There the two unique machines for machining have been supplied by Maquinser, for aluminium and carbon fibre. A project where we included new technologies both for scanning the probe, programming, all automated, and most importantly: the machining of the largest piece of carbon in record time to date, and has been a project key in hand in its entirety.

Is it the future? Already they are standard machines?

What we do is the standard model adapted to the needs of the client. In the case of the A400-M was a project that became the Department of engineering with 'rapid prototyping' because we had to adapt each of the pieces to each of the aircraft. Each piece is different. So of CAD, CAM and posprocesado technology was included to make the machining and did it entirely Maquinser engineering in close collaboration with the client.

A serious relationship

It is important to reference to Modesto Porto that Maquinser has clients throughout the Spanish geography. The firm has machines installed in reference for the aeronautics sector companies as: House (1), EADS CASA (2), Airbus Military (1), Consur (14), Seville Control (10), Inespasa (9) group Aciturri, National Institute of technical aerospace - Inta (8), General Dynamics (4) and Novalti (1), among many others.

Airbus has also commissioned them a Famu machining center to manufacture supplements tailored to fit the wing for the A350 XWB...

This is the project in which we are working now, that we will deliver in the summer. Another turnkey project is for Airbus Illescas, in the case of civil aviation.

What is this machine so they request in this plant?

The truth is that we adapt a model of all those who have our represented firms we believe that better solve the needs of the client. In this case in particular, this machine must be machined fibre of carbon, not only recanteado, which is quite common, but also milling surface with very high precision, boring and all the machining operations of carbon fiber. This requires a machine with linear motors, 90 m/min, i.e., a high-tech machine, but who then, in turn, implies a more productive solution and that it encompasses the industrialization, construction equipment, Automation control of Scada-month production through custom software made by us.

In the design of the equipment we have achieved savings more than 250,000 euros in cost to the client, thanks to a more effective and flexible proven solution, which is almost more important than the cost, because these projects models of piece undergo constant modifications and reaction time is vital.

Then you have to also take into account the environmental conditions required by this application, the carbon fiber is clean, this machine, that series is already carenada, you need an outside cabin which, in turn, contains the machine for double protection, with their systems of aspiration, filtering, etc. which requires demanding current environmental legislation.

I see that in this case the cooperation with Airbus was basic but I understand that it is the work of Maquinser mode: working with the client to decide what the best solution that can offer you.

Effectively. The client presents a project, tells us what production system have and want to know what machine, among which we sell, can help you to improve. We work side by side with them and propose our choice. We have a fairly wide range of product and why it is in our hands select the most appropriate based on what the client is proposed.

In fact isn't the first time that they work for Airbus - or will be the last, either civil or military sector as the implementation of the FAL (Final Assembly Line in Seville for Airbus Military - can detail what projects carried out in the FAL?

It is that Maquinser is approved by Airbus as a supplier. Our contribution was in the initial start-up implementation and further enlargements are not ruled out. There is are mecanizing the pieces that are assembled the wing of the aircraft with the body. And what they are looking at now is to mechanize the entire wing. Make the application on the mounted wing, but the truth is that it is an issue which is blocked in part by the economic situation.

This machine will be given in Airbus Illescas is group Parpas, whose machines sold from October 2009. It is a company which knows very well sectors such as aeronautics, but also the energy, rail, moulds and dies... was a boost for Maquinser in these sectors?

We have had the misfortune that when we started came us the crisis over. But one of the expectations we had with this signature was, precisely, as you said, get more in the wind sector, for example. But today the entire energy sector is very stopped. Although I have to say that we have already experience in the wind energy in particular. Our customers, and very important in the sector such as Endaki, Murua, Indae, CMA or Paramio, for example. But it is true that machines Parpas complementary part of the range not available so far. Anyway, for the wind sector we already have significant as SNK and Toshiba products.

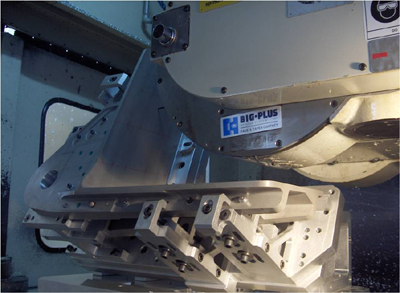

It's a 72-63V MAM with pallet change, and is already the third machine of the Japanese manufacturer, provided by Maquinser. Previously Inespasa in production a MAM 72-25 also had 5-axis, and a horizontal center HPLUS 630.

The newly installed machine has a head BBT 40 of 12,000 rpm and 90 tools Matrix charger, expandable to 240, measurement and Renishaw laser equipment. Inespasa has purchased this machine to be able to complete the workload for the supply of parts for the aeronautics sector to various projects of its customers: Airbus, Embraer and Bombardier.

MAM 72-63V represents the third machine of Matsuura provided by Maquinser in recent years, in addition to the two SNK and others up to a total of 9 machines.

The collaboration between Inespasa and Maquinser, begins in 1998 and remains to the present day. The quality and reliability of Matsuura, along with a professional service close to the customer, the experience of the technicians of Maquinser Engeneering applications in the aeronautical sector, are critical factors to maintain the trust of customers.

Generally speaking more of the company, what forecast do this year? The aeronautics sector will play an important role?

Yes, in that we trust. The current situation, it is increasing the number of pieces of titanium in aircraft and also is gathering momentum to the carbon fiber... so we anticipate that it will report a significant increase in the sector.

The truth is that we believe that it will be better than last year. The best sales year was 2007 and in 2008 billing, because we must bear in mind that the deadlines for delivery of the projects tend to be long. 2009 was a really bad year and 2010 recovery, especially the last four months. And we hope that 2011 is better without, obviously to 2007 levels. However there is a slow recovery from the metalworking sector in general, although more slowly than is desirable.

However, we are optimistic. In Catalonia we have for example with 7 set up for the next two months, many with engineering. In the area of Madrid have also entered new projects, and the sector of the car in the Basque country is clear improvement.

Also added the entry into force of the Act of delinquency which has increased the problem. SMEs are paying a maximum of 60 days and 120 days, without the possibility to collect most deduct role either by your bank or by your customer to pay for transfer without allowing twists or factoring. In this context the weak finances customers, implausible as it sounds. It's a good idea with difficult to implement due to the lack of sanctions.

The upside is that companies have put their sights in foreign markets where payments are guaranteed in less than 60 days in the majority of cases.

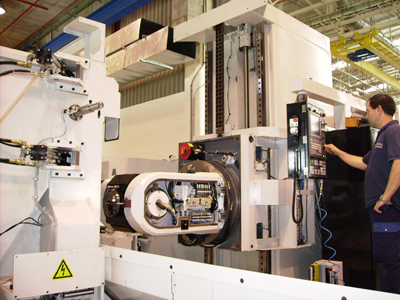

Maquinser has recently completed the implementation underway of a machining center of the Japanese company SNK in Consur. In this case it's a HPS120A specially designed for machining titanium. This design, designed especially for the work of parts in aeronautics, has as main characteristic the movement of the Bureau of 1,200 x 3,048 mm, which allows the loading of the piece in level to oscillate then 90 ° allowing an optimal evacuation of shavings. The head of 5-axis are available horizontally to the piece. The routes of the machine are X: 3,150; AND: 1. 500; Z: 1000 mm.

In this case the Consur client has decided for a machine specially designed for the machining of titanium. The machine incorporates a printhead BBT 50 5000 rpm and 1,000 Nm of torque, equipped with internal cooling through the center of the tool to 50 bar, and has a few outsized prismatic guides to ensure the rigidity of the demanding machining of titanium. It also incorporates a charger 120 tools, Balluf identification system for tools, and Blum and Renishaw measurement systems.

CONSUR, provider of reference for the aeronautical sector is relying on Maquinser since its inception. The first Matsuura machines were delivered in 1988 and until now the cooperation between the two companies has been excellent as demonstrate the six machines of the Japanese brand that has, along with 9 of SNK, for a total of 15. The quality of the product SNK, who have been relying since always, the proximity of the technical service provided by Maquinser with own delegation in Seville and the experience of the technicians of Maquinser Engeneering applications in the aeronautical sector, are decisive factors for that the cooperation between the two companies have been going des of more than 20 years ago, and present a few excellent omens for the future for both companies.

What other areas do you think that they can make more billing to the company?

The automotive industry. It is in fact already being important. But we do not necessarily speak in the Spanish market. The major manufacturers, Tier 1 and so on, have offices in other countries, but if the plants are here, we continue to make them projects, although the final installation is out of Spain.

For example, we have now achieved a turnkey project for Brazil but the acceptance of the process will take place at our facilities and then will be sent and install on the final destination.

It is an availability and service that we offer to all our customers. Both aircraft as automotive. Our experience in these markets allows us to offer the customer an already done project to be extrapolated to other locations outside of Spain. It is further proof of the trust our customers place in us.

When told that they make projects to locate in other regions such as China, etc., is the design of the machine to what extent is determined by destination?

A lot. Not only by the regulations, but so prosaic as voltage issues. Brazil for example we have to carry refrigerated and tropicalizados, engines for the degree of humidity. All this must be taken into account. Security systems are not the same, even providers there are not that always work but they should choose to give the best service possible while they are an envelope cost. It also influences for example if the labour force in selected countries remains economic, they ask for machines with manual loading. The degree of automation is not which is required in Europe.

Finally, do you have a project for the world of Aeronautics that can move me?

Some of us have. It must be taken into account as there are clients subcontractors that they are entering new jobs. And it also reverts in suppliers like us. In addition, the A350 is beginning to enter series production, so this will create a lot of work also.