Application of Base B & R CNC: hardware + display + simulation

December 20, 2010

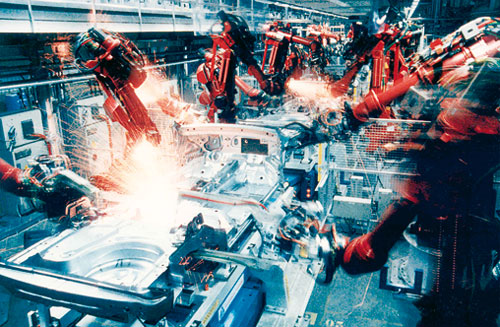

The production of machinery is an innovative field: in recent years technological developments have enabled the industry to advance in leaps and bounds. Due to the demands of the customers, who wanted to increase their productivity, machinery manufacturers have merged the functionality of several machines on a single in order to reduce unproductive time. The result: increasingly there are more axes moving, you need a higher positioning accuracy and has less time to calculate interpolation. In addition, increasingly there are more sensors and actuators connected, which require more inputs and outputs. At the present time, in which production processes have already been optimized to the mechanical limits, many are focusing on reducing the internal logistics processes, automate entire production Islands. At times even production lines and entire production centres.

On the other hand, the machinery manufacturing industry is not so revolutionary. They use technologies and well-established traditional developments that do not leave until that they do not become an impediment to a new development. Traditionally, the automata controlled processes with inputs and outputs, while the CNC controlled movements. They were two completely separate areas. For many, the robot controllers were even another area. As a result, some prestigious manufacturers of automation equipment still continue to offer CNC solutions that use a hardware for the control of inputs and outputs and one for the control of movements. These teams use a different programming methods and may not be monitored in the same pane, thus hindering the development of applications that combine a large number of axes, multitude of sensors and robots.

Long time customers of B & R have been able to develop these applications in a much simpler way. On the one hand, there is great potential in the hardware: the Acopos are servo with built-in intelligence and in addition to the Powerlink can add you all kinds of peripherals. On the other hand, the software solution is very effective: Automation Studio allows to develop the entire application in a single project, including the functions of PLC, visualization, the 'motion', CNC and robotics.

Large machinery manufacturers appreciate the liberty B & R provides them to combine the tasks of processing positioning and visualization, as well as the ease with which you can synchronize and run at high speed, even in more complex cases. An example is the Austrian machinery makers Fill. Its processing Robmill Center, manages the Robotics, processing of PLC and CNC functionalities on same hardware with the concept of software called 'generic motion Control'.

However, not only the major manufacturers of complex machinery can and must invest a great effort in the development of automation. Most of the manufacturers of CNC continuously develop new products to offer more useful solutions to its customers. This requires the use of a more complex programming, with the integration of more and more axles, minimizing the space required and increasing energy efficiency. These companies take advantage of the opportunity that has the Generic Motion Control combine CNC with PLC functionality, as well as using simultaneous and synchronous motors, stepper motors and hydraulic axes on the same hardware platform and an integrated visualization system indistinct. Also, the use of inputs/outputs and safety connected via Powelink equipment saves space and is handled in a completely uniform way thanks to Automation Studio.

Even so, machinery manufacturers need more: need a standard package that covers all the basics of a CNC, which use the most modern and efficient technologies available in each area and make it easy to implement without losing ease of easily extend it according to own needs. This package should serve as a basis for the development of each machine without requiring a Development Department to modify it. In short, a package of initiation for machinery manufacturers who wish to focus its efforts on its area of competence, but which at the same time want to have the maximum support from hardware and software.

Application of basis for CNC machines

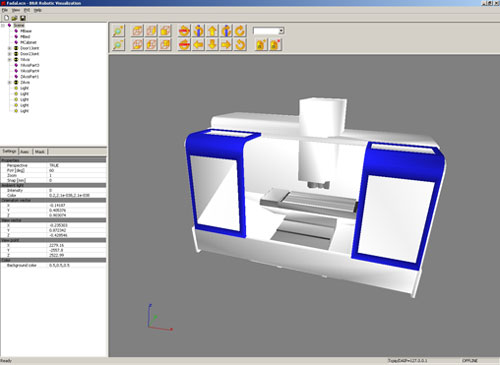

B & R has noticed this need and has developed its standard package of CNC. For the first time, machinery manufacturers have access to a complete and homogeneous solution that provides all the key features of the CNC, a system of standard display and easily adaptable and even specially developed simulation tools to work without hardware.

The visualization application was developed so that it is fully functional and can be used as is, without performing any changes. The application of visualization has been developed with Visual Components and the manufacturer can use it as is, but can also modify it, extend it or simply adapt it to your corporate image. The application consists of seven pre-programmed operation modes, which can be used directly, which is the automatic, the execution block to block and simulation.

In an environment of typical CNC, the display has to be able to show large lists of programs, but at the same time has to be sufficiently compact and simple to handle the machine. For this reason has developed a special panel with a screen of 15 "with portrait orientation, with numerous function buttons which allow operation in adverse environments, as it can be operated even with gloves. It is usual that the operator has to enter manipulate the machine at distance from the control panel, has also developed a portable remote control which allows to manipulate the machine from any position of its perimeter.

This hardware using the Automation Runtime operating system, which also is responsible for multitasking management in real time. The functionality of the CNC runs on the same processor as the rest of the PLC control programs, so it has no place in a separate control as do other manufacturers. The system thus eliminate communication delays allowing further shorten cycle times.

In contrast to many other architectures of CNC available on the market, which only provide a channel, the solution of B & R has no such limitation. Currently there still is a logical limitation of 8 channels of CNC with 9 axles each, but in short this limitation will be thing of the past. From then on, the only limitation that there will be will be the calculation of used CPU power.

The package also includes a simulation environment in real-time that runs on Windows which is intended for an Office environment. This tool allows a complete simulation of the machine and/or CNC who can even simulate 'hardware-in-the-loop'.

Many of our competitors have been providing for many years packages CNC machinery manufacturers. The Base implementation of CNC in B & R is not only a software package it ready to be used, but it also provides a platform ready to develop and innovate a custom application to the manufacturer. Thus the manufacturer can offer a value added technology to its product, applying and protecting an oriented know-how to improve the productivity of its customers.