The folding TruBend 7000 reach records folded with the B & R technology

September 10, 2010

In 1968, Trumpf released Trumatic 20, the first folding machine of metal with CNC in the world and with a fully automated operational sequence. Based on the technology of perforation plates, was a real feeling in the sector of sheet metal processing.

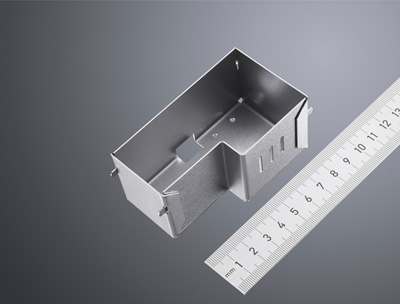

TruBend 7000 series folding presses that were presented at the Euroblech 2008, was a similar milestone in the development of this sector. Perfectly adapted to also manipulate small components whose total area is less than a DIN A3, this new series machines significantly improve the energy efficiency of the process. Not only is the fastest folding press in the world, but it also provides an ergonomic environment for comfortable handling thanks to its human-machine interface. This is accomplished because it manipulates sitting, to the contact surfaces can be adjusted and the Assembly of the control. The processing zone is illuminated by a system that incorporates technology iLED used in the medical sector of Trumpf products and that illuminates without heat in the area of manipulation of the user. It also allows to generate a laser on the line to bend, so the operator can check if the accused is correct.

The presses of the 7000 series have lightning manipulated high acceleration and speed thanks to a lightweight fiberglass media and control that it performs an engine's torque. Besides getting a few movements of a demanding dynamic, they succeed with a very low consumption.

Seeks to control for torque motor

As a great innovator in the sector of metal processing, the decision of Trumpf use this relatively new technology, was a development in unknown territory. At the end of the year 2005, the search for a compact and powerful control solution for the torque engine, led to their engineers to solve ACOPOSmulti who was then beginning to see the light. Energy efficiency which reach thanks to the regeneration of current, a simple Assembly and the effective implementation of a limitation of torque to prevent accidents, joined an excellent dynamic behaviour to finally become the chosen solution.

Finally convince Trumpf technicians, there were some elements which surpassed its own requirements, such as the possibility of deploying security technology without adding any hardware. ACOPOSmulti is able to do this thanks to its 2 disabling entries that meet category 4 of EN 954-1, which corresponds to a level 3 of IEC 61508. It was especially important to comply with the requirement to turn off the driver in a safe way to dispose of a braking secure enough to not have to take into account the pair might even develop engines during this process.

Total dynamic control

Trumpf wanted to continue to work with your provider of automata: "We had a fluid relationship and the level of satisfaction was good," explains Alfred Hutterer, executive director of Trumpf Machinen Austria GmbH & CoKG. "His experience with hydraulic axes us was very useful, especially in the technology of 4-cylinder using the TruBend 5000 series".

However B & R was able to convince Trumpf to integrate all the automation of the machine in a single solution. The requirements of speed of the machines of the 7000 TruBend series ended by unbalance the balance. We had to control a total of 8 axes with speeds and very high accelerations, implying a very short cycle times with a very fast, and also coordinated reaction with a periphery that should operate in a very fast deterministic bus.

All this was achieved with the APC 620, managed by the operating system AR010, which controlled the entire process automation including X 20 i/o modules. The ACOPOSmulti servo are connected via Ethernet Powerlink. A really special feature is that Windows works in the industrial PC in parallel to the environment of the operating system to display the view on the touch screen by means of the interface from Trumpf.

Faster customized developments

The final decision to opt for B & R allowed the integration of all the cylinders in a single project in Automation Studio. Thus was achieved rapid development thanks to the Elimination of interfaces. Trumpf benefited greatly from this rapidly developing, as explains the doctor Hutterer on a truly exceptional situation for a machine tool manufacturer: "as soon as we plugged the first prototype, we got a pleasant surprise"": all the elements of the machine ran the first". Even during the following preserial with some of our most trusted clients, users did not have any problem, what they really excited. Thanks to this technology from B & R, Trumpf engineers were able to reach a new world record in bending of metal with the new TruBend 7000-series machines.