The plastic containers are gaining ground thanks to the r & d

June 29, 2010

The development of plastic materials for packaging applications is in continuous growth, the new processes of polymerization, the use of nanocargas, the different formulations and the improvement of the processes of transformation, they make plastic packaging from accessing some applications which until a few years ago were unthinkable.

At the end of 2009, the technological Institute of plastics (Aimplas) organized the seminar I in packaging plastics. In this meeting were presented the latest developments in plastic containers, many of them already commercialized and it was put in evidence that plastics are more alive ever and the limit of applications that can reach still is unknown.

Co-inyectados packaging

As examples of these new products, from Aimplas co-inyectados packaging which can be alternative to metal containers for canned foods, as the co-inyección process allows combining two materials with complementary properties have been developed. In this line Aimplas has worked on two projects.

The first of these, already finished, with acronym Activepack, has focused on the development of active packaging with antioxidant properties to prevent the degradation of fatty compounds of processed foods. The project, which has involved the Ministry of industry, tourism and trade, has been to combine a material with thermal, and mechanical resistance as the polypropylene, a material that provides barrier properties to gases, and that favors the conservation of food, as the EVOH. Also on these containers are tested active systems such as scavengers and sequestrant of oxygen and natural antioxidants with the aim of increasing the useful life of packaged food. These packages are ideal for application in canned foods.

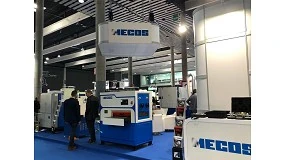

The second project, Cobapack (project Craft) is about creating a new recyclable packaging based on renewable materials and manufactured by co-inyección. It is a project within the 7th programme framework of the European Union developing at the moment. The project is to obtain packaging co-inyectados combining PP or HIPS as external materials with good mechanical and thermal properties with starch in the inner layer, providing barrier to oxygen (Figure 1). Starch, moreover, increases the sustainability of the packaging it comes from a renewable source, has a lower cost to materials as the EVOH barrier and to be soluble in water makes the process of recycling, there is a stage in the process of traditional recycling of grinding and washing, and it is the latter where separated the starch of the plastic material.

Biodegradable products

On the other hand, the development of biodegradable products is at a peak. After ten years of research in this field, Aimplas have developed products on demand for different applications. Film and trays for food use, plastic bags, tutors, meshes for packing fruit, are some of the developments taken Aimplas to different companies with materials 100% biodegradable and compostable. Products under controlled composting conditions "disappear" in less than 6 months.

New raw materials

The enterprise initiatives of the plastic at the national level, have not been left behind. With regard to raw materials, Novapet has developed a degree of material from PET called Glasstar which has an appearance very similar to the glass, so it makes it suitable for applications of catering and in sectors such as perfumes and cosmetics. (Figure 2).

On the other hand, the company Nurel is working with nanocargas in polyamides. These charges can increase the barrier properties of materials, thereby increasing the range of applications. The addition of the loads is performed in the polymerization process so that you get a proper distribution which allows the maximum effectiveness of the Nanocomposites.

In a very similar line, the Nanobiomatters company, is working with this type of loads. The fundamental difference is that in this case the nanocargas are added through a physical mixture in the phase of compound, developing tailor-made solutions on the basis of the final application.

Other companies such as Repsol, Borealis, Dow Chemical or DuPont, are working with new catalysts for materials with new or improved properties. New copolymers that favor sealing, more transparent polypropylene and polymers with better mechanical properties are some of the latest developments.

Manufacturers of machines and technologies

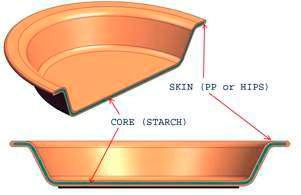

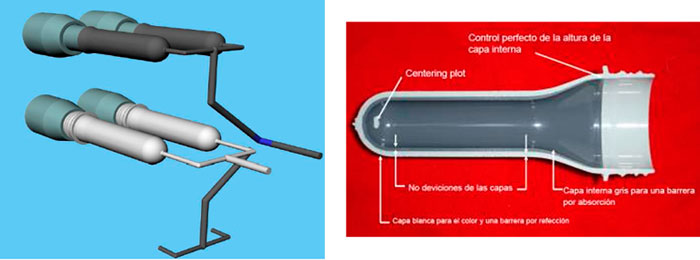

As for manufacturers of machines and technologies for processing are two new technologies. For a side, EDI has developed an extrusion head of laminating flat to obtain multilayer structure with a high number of layers which allows to obtain a plate final with better mechanical properties or barrier to the classical distribution (Figure 3).

Netstal has finally developed a co-inyección system for preforms from PET to the manufacture of bottles for dairy products. This process allows obtaining bottles with very good properties of preservation of the product, in a more productive process and obtaining structures with a single material in two layers, PET, which facilitates the recycling (Figure 4).

The efforts of r & d in enterprises, agencies of funding and technological centres, as Aimplas, put in cutting-edge plastic materials as reference material in the manufacture of packaging. In this sense, Aimplas is providing support to the companies in the plastics sector and end users to carry out its r & d initiatives, helping in the search for financing, the technical development of the project, the validation of the product and the dissemination of the results.